Method of producing leisure foods with shrimp shells and dried small shrimps

A snack food and shrimp shell technology, which is applied in food drying, chemical preservation of meat/fish, food science, etc., can solve the problems of narrow market sales, single form of shrimp skin products, etc., to extend shelf life, improve taste and edible sex, taste improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

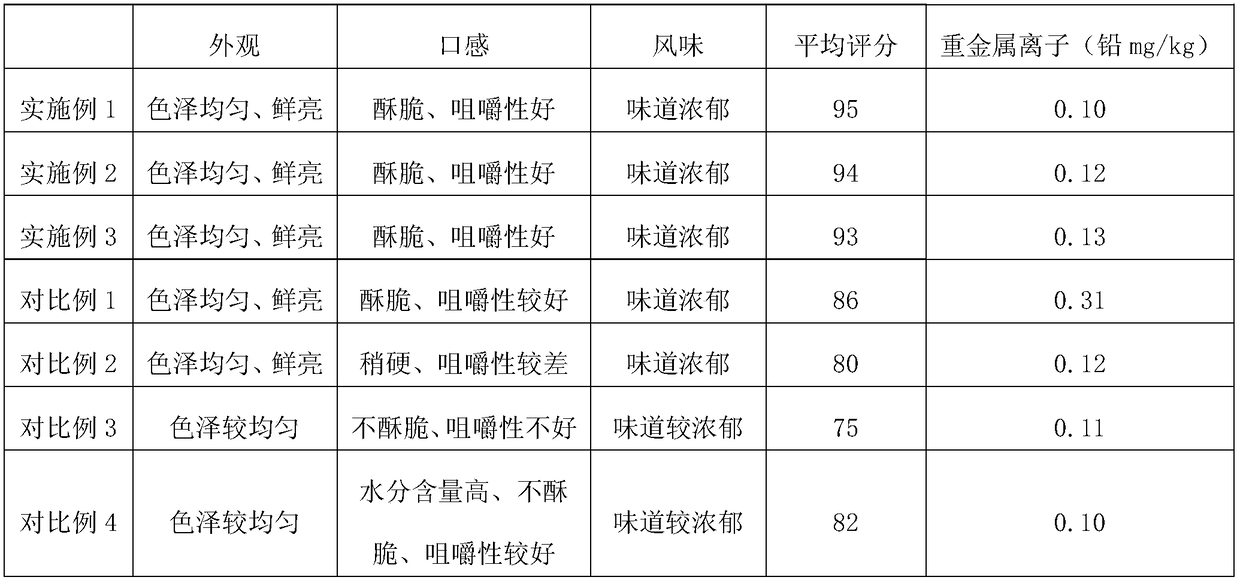

Examples

Embodiment 1

[0035] A kind of method utilizing shrimp shell and shrimp skin to prepare snack food, comprises the following steps:

[0036] S1. Preprocessing:

[0037] Shrimp shells and shrimp skins are removed from impurities, cleaned, drained and water controlled, then soaked in the pretreatment solution for 1 hour, then rinsed for 20 minutes, soaked shrimp shells and shrimp peels in sterile water for 2 hours, and the sterile water is Ozone treated water. Finally, it is dried with hot air at a temperature of 65°C.

[0038] The pretreatment liquid includes the following components according to mass percentage: 2% soluble chitosan, 0.5% glacial acetic acid, 5% salt, 0.3% lecithin, 0.5% zeolite powder, 0.2% lysozyme, and the rest is sterile water .

[0039] S2. Softening:

[0040] High-pressure steam is used for softening treatment, the softening temperature is 125°C, the pressure is 0.12MPa, and the softening time is 15min.

[0041] S3. stereotypes:

[0042] The softened shrimp shell ...

Embodiment 2

[0051] A kind of method utilizing shrimp shell and shrimp skin to prepare snack food, comprises the following steps:

[0052] S1. Preprocessing:

[0053] Remove impurities from the shrimp shells and shrimp skins, wash them, drain them and control the water, add them to the pretreatment solution and soak them for 2 hours, then rinse them for 10 minutes, soak the rinsed shrimp shells in sterile water for 3 hours, then take them out and dry them. Finally, it is dried with hot air at a temperature of 70°C. The sterile water is ozone-treated water.

[0054] The pretreatment solution includes the following components according to mass percentage: 3% soluble chitosan, 0.3% glacial acetic acid, 8% salt, 0.1% lecithin, 1% zeolite powder, 0.1% lysozyme, and the rest is sterile water.

[0055] S2. Softening:

[0056] Shrimp shells were softened by high-pressure steam at a temperature of 130° C., a pressure of 0.1 MPa, and a softening time of 10 minutes.

[0057] S3. stereotypes:

[...

Embodiment 3

[0067] A kind of method utilizing shrimp shell and shrimp skin to prepare snack food, comprises the following steps:

[0068] S1. Preprocessing:

[0069] Remove impurities from the shrimp shells and shrimp skins, wash them, drain them and control the water, add them to the pretreatment solution and soak for 0.5 hours, then rinse them for 30 minutes, and finally dry them with hot air at a temperature of 60°C. The sterile water is ozone-treated water.

[0070] The pretreatment liquid includes the following components according to mass percentage: 1% soluble chitosan, 1% glacial acetic acid, 8% salt, 0.5% lecithin, 0.3% zeolite powder, 0.5% lysozyme, and the rest is sterile water.

[0071] S2. Softening:

[0072] High-pressure steam is used for softening treatment, the softening temperature is 120°C, the pressure is 0.15MPa, and the softening time is 20min.

[0073] S3. stereotypes:

[0074] The softened shrimp shell and the pretreated shrimp skin are mixed evenly with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com