Contra-rotating floor scrubber and floor scrubbing brush thereof

A technology for scrubbing brushes and scrubbers, applied in the field of scrubbers, can solve the problems of high labor intensity and easy fatigue of operators, and achieve the effects of reducing labor intensity, easy control and stable direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

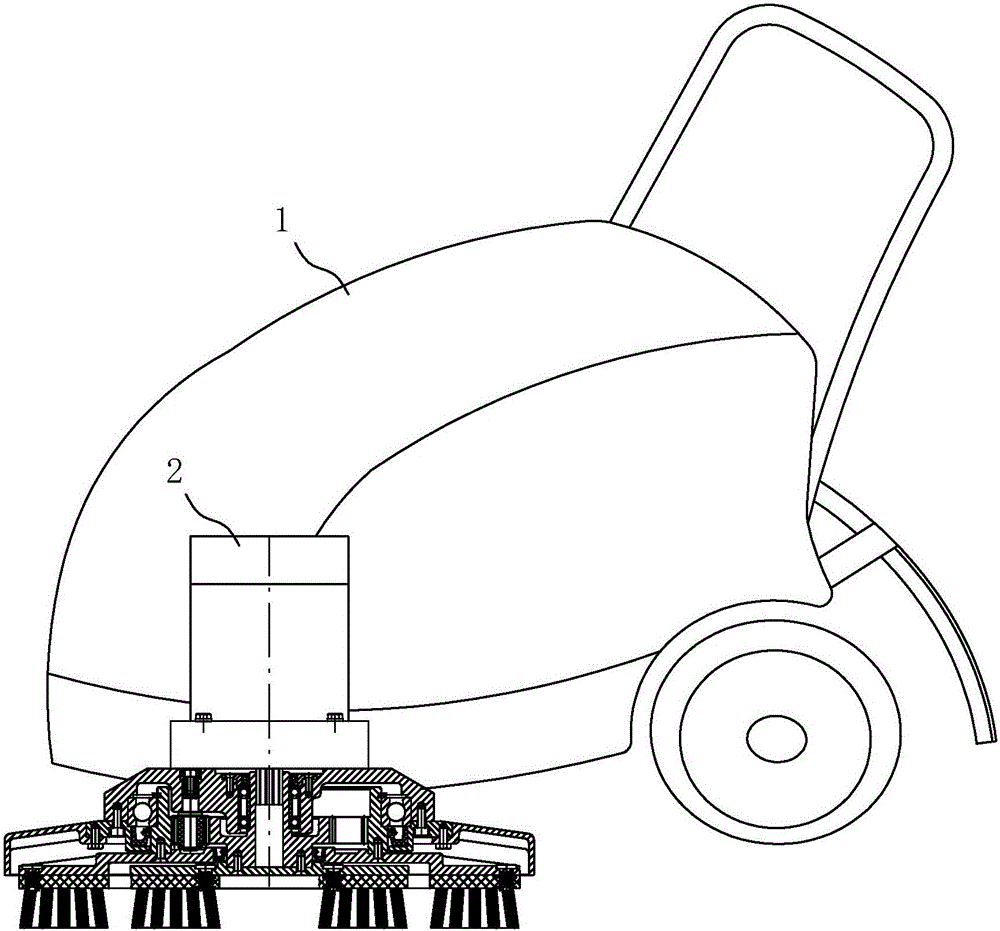

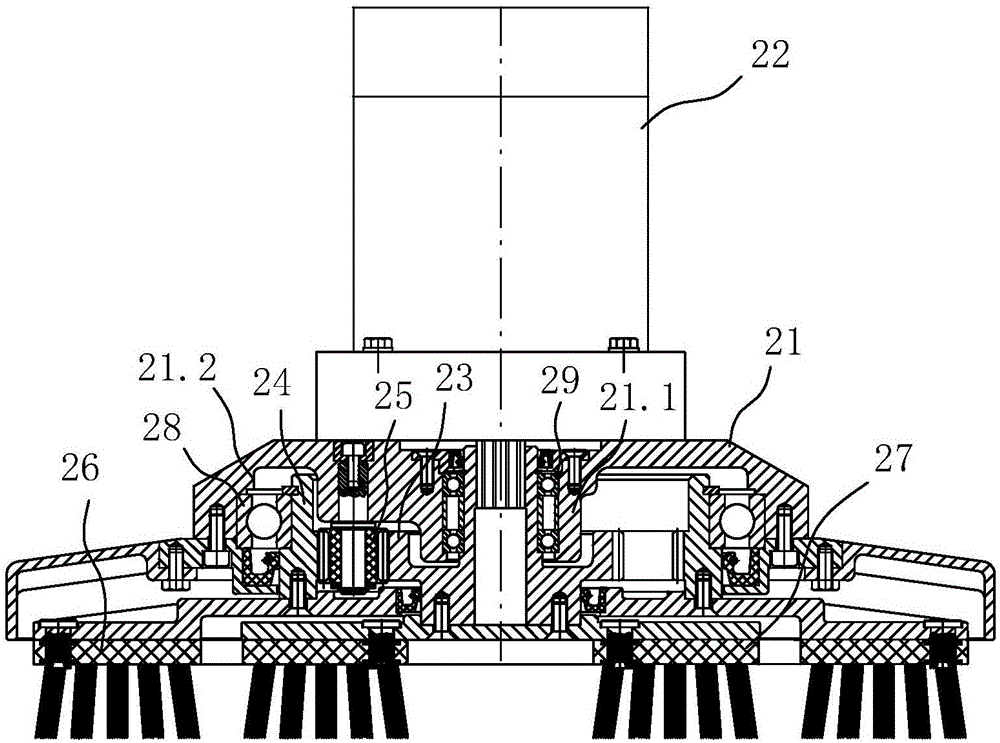

[0011] Such as figure 1 , 2 As shown, a counter-rotating washing machine, the front end of the main body 1 of the washing machine is equipped with a washing brush 2, the washing brush 2 includes a top seat 21, a motor 22 is fixed on the top seat 21, In the present invention, the bottom of the top seat 21 is provided with an outer ring gear 23 fixed to the main shaft of the motor 22, and an inner ring gear 24 is provided. The gear 25 of the outer ring gear 24 is equipped with an outer turntable hairbrush 26, and the bottom of the outer ring gear 23 is equipped with an inner turntable hairbrush 27.

[0012] The motor 22 is started, and its main shaft drives the outer ring gear 23 to rotate, and the outer ring gear 23 drives the inner turntable brush 27 to rotate, while the outer ring gear 23 rotates and drives the inner ring gear 24 to rotate reversely through the transition gear 25, and the inner ring gear 24 then rotates Drive outer turntable hairbrush 26 to rotate. Because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com