A method of changing into discrete additive casting for preparing homogenized ingot

A homogenization and ingot casting technology, which is applied in the field of discrete additive casting for the preparation of homogenized ingots, can solve problems such as not being able to meet the needs of equipment construction, achieve obvious solidification shrinkage, reduce macro segregation, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

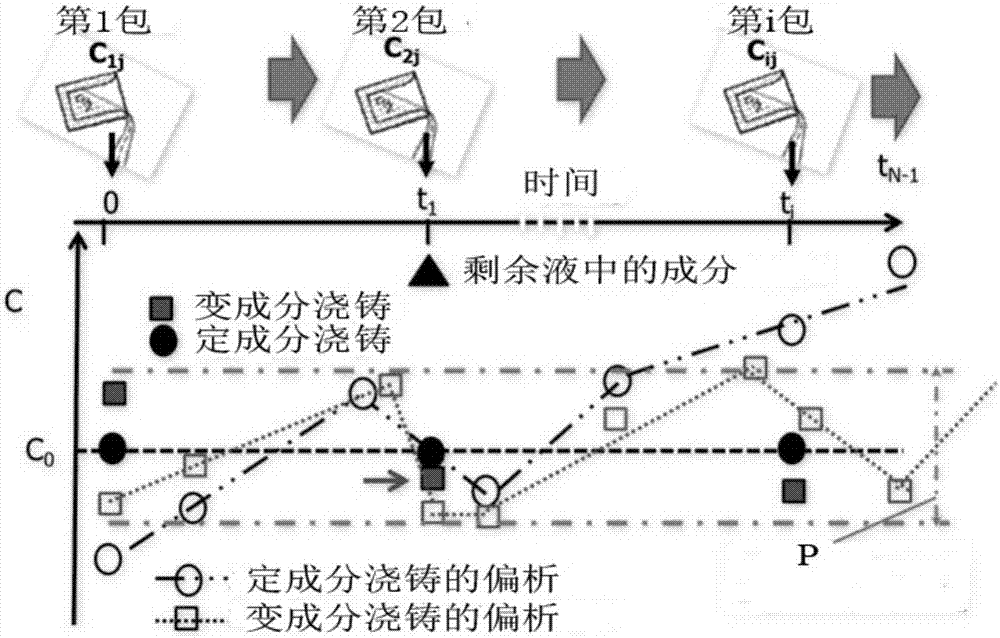

[0043] Because the experimental preparation cost of a hundred-ton large-scale ingot is huge, a numerical simulation method is used to verify the method of the present invention. In this embodiment, a steel ingot with a height of 4.4 m and a diameter of about 2.4 m is used as the research object, and the carbon content is 0.2%. The ingot will be discretized into 10 packs for variable composition casting, and the implementation steps are as follows:

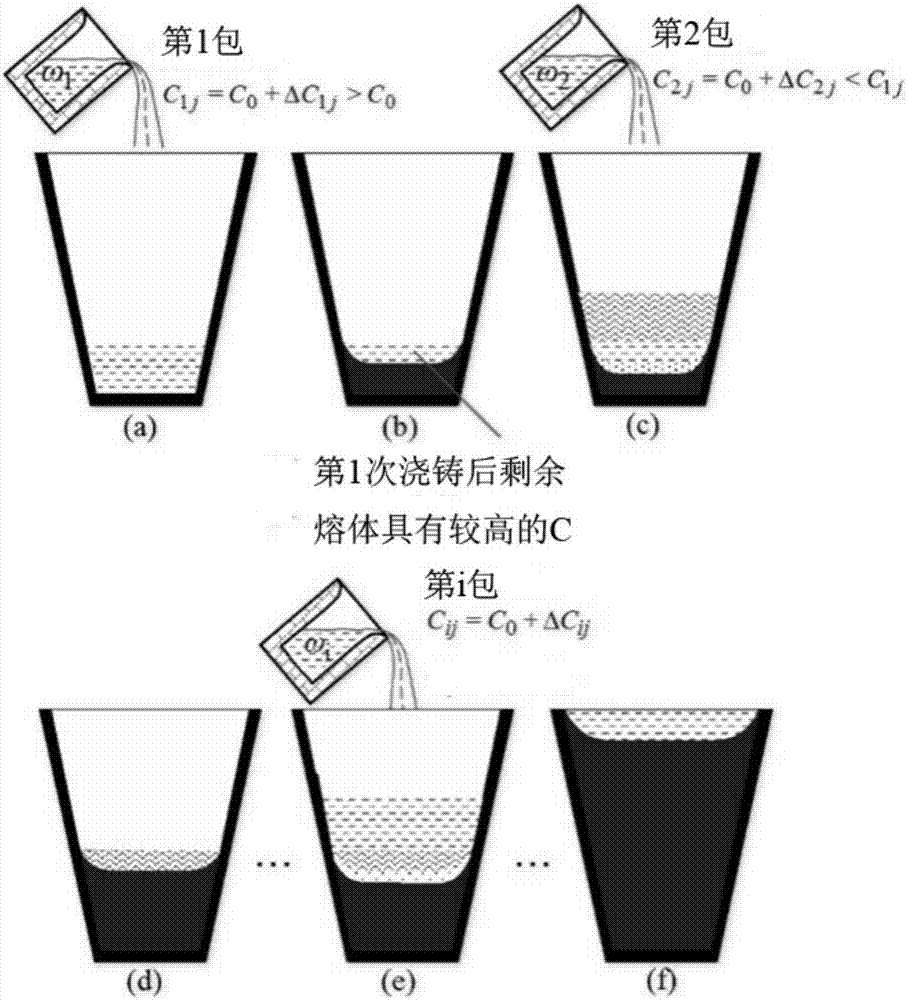

[0044] (1) Carry out the first ladle casting, wait for it to solidify until the solid phase ratio reaches 80%;

[0045] (2) Measure the remaining molten metal composition in the previous step, and calculate the composition of the next bag according to the model;

[0046] (3) Carry out next bag casting, treat that it is solidified to solid phase rate and reach 80%;

[0047] (4) Repeat steps (2)-(3) eight times until the ingot is formed;

[0048] The weight of the ingot in this embodiment is about 100,000kg. By comparing the macro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com