Discrete casting method for preparing homogenized cast ingot

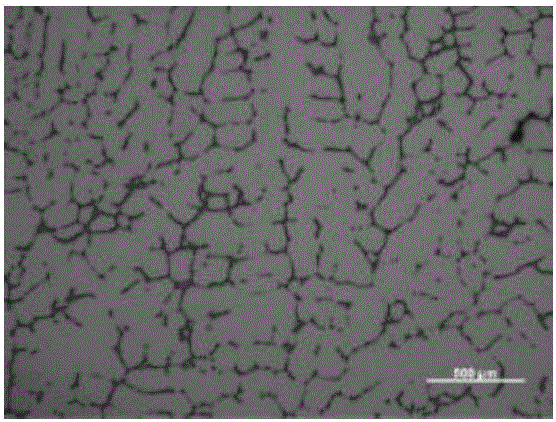

A technology of homogenization and ingot casting, which is applied in the field of discrete casting for preparing homogenized ingots, can solve the problems of scrapping performance, uneven grains, cracking of forgings, etc., and achieves reduction of shrinkage defects and fine grain size , the effect of increasing the nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

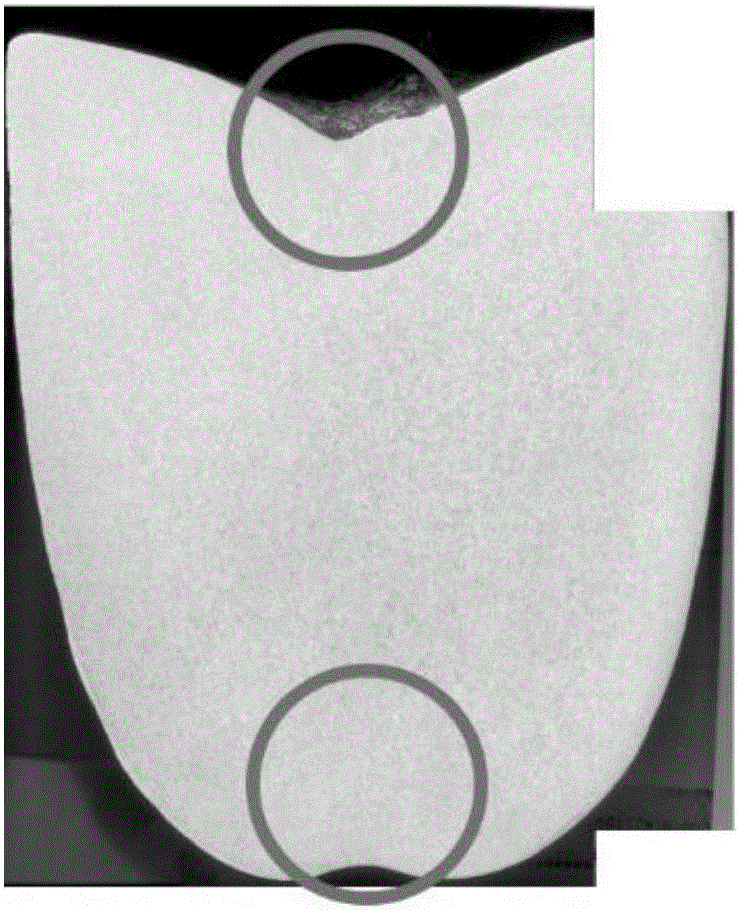

[0044] In this example, a graphite crucible with a height of 140mm and a diameter of about 130mm is used as the ingot mold, and aluminum-copper alloy is used as the experimental material. The ingots will be separated into 4 packs for casting. For comparison, an ingot of a traditional casting method was cast under the same conditions as follows:

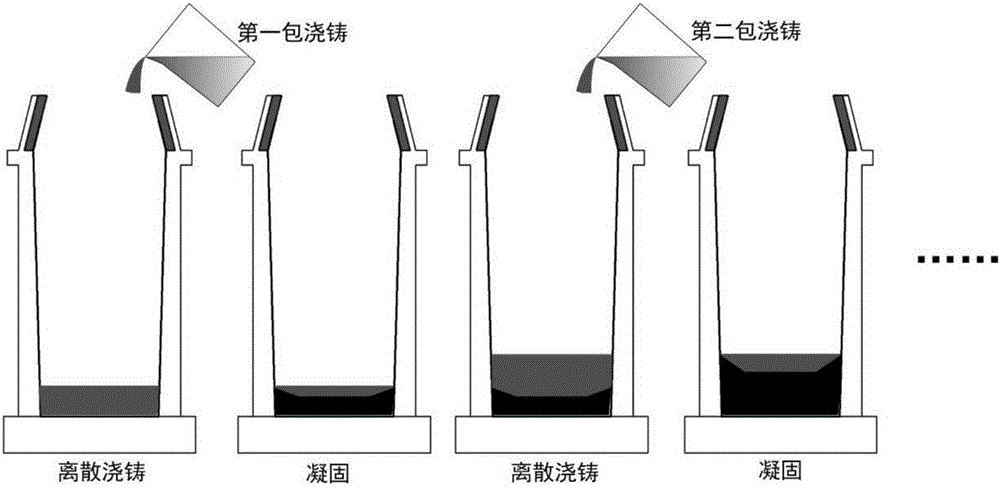

[0045] 1. Using the numerical simulation method to calculate the solidification process of the ingot, it is predicted that the pouring intervals of the second bag, the third bag, and the fourth bag are 30s, 45s, and 60s respectively;

[0046] 2. Add pure aluminum, raise the temperature until it melts, add aluminum-copper master alloy, refine and let the melt keep at 750°C to prepare for casting;

[0047] 3. After casting the first bag, wait for it to solidify for 30 seconds, start casting the second bag, cast the third bag after 45 seconds, and cast the last bag after 60 seconds;

[0048] 4. Casting an ingot using traditional castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com