An external counterpart for barrier-free welding of pipelines

An external counterpart and barrier-free technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor fusion, insufficient strength, small positioning solder joints, etc., to reduce labor intensity and reduce assembly Effects on incompatibility and avoidance of welding obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

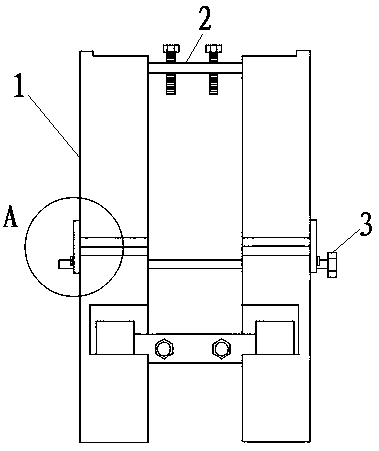

[0037] As shown in the accompanying drawings, this patent is an external counterpart for barrier-free welding of pipelines, which is used for butt welding of pipelines.

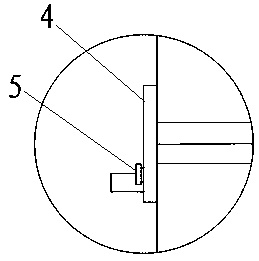

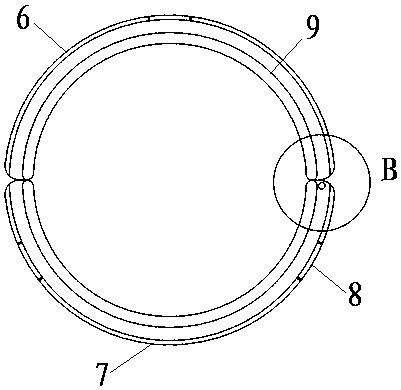

[0038] The snap ring 1 includes an upper half ring 6 and a lower half ring 7; the upper and lower half rings 7 are symmetrically arranged to form a circular ring; the outer sides of the two ends of the upper half ring 6 are respectively provided with a first connection protruding from the upper half ring 6 ports Sheet 4 and the second connecting piece 11, the first connecting piece 4 and the lower half ring 7 are provided with a pin shaft 5, and the second connecting piece 11 and the lower half ring 7 are provided with corresponding through holes 10; the pin shaft The upper and lower half rings 7 on the outer side of the 5 are provided with gaps, and the gaps are used to make the upper and lower half rings 7 of the snap ring 1 open, so that the snap ring 1 can be stuck on the pipe to be welded.

[0039] Both ...

Embodiment 2

[0046] It is the same as Embodiment 1, but the upper and lower surfaces of the slider 12 are inlaid with free-rotating balls, which is to further facilitate the sliding of the slider 12 in the circular chute.

Embodiment 3

[0048] Same as embodiment 1, but the tightening bolt 13 is provided with a handle, which is for the convenience of workers to loosen and tighten the tightening bolt 13 without other tools, so as to save working time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com