A fixing device for pipeline welding in building construction

A technology for building construction and fixing devices, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of poor fusion, insufficient strength, small positioning welding points, etc., so as to reduce labor intensity, improve construction efficiency, and avoid welding. The effect of obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

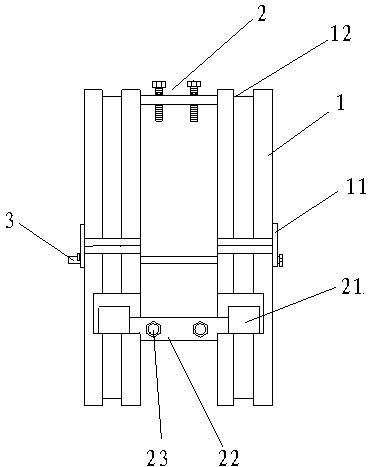

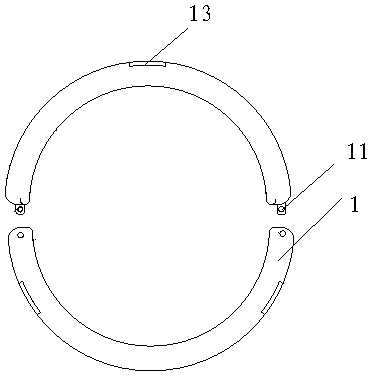

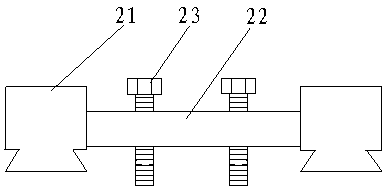

[0026] as attached Figure 1-3 As shown, a fixing device for pipeline welding in building construction of this patent includes two fixing rings 1, four sliding fasteners 2 and positioning connecting bolts 3;

[0027] The two fixed rings 1 include two symmetrically arranged circular rings and two pin shafts; each fixed ring 1 is composed of two half rings; connecting pieces 11 are arranged on the outer sides of both ends of one of the half rings, and the connecting pieces 11 There are pin holes on the top; the two ends of the other half ring are provided with the same pin holes as on the connecting piece 11; one end of the two half rings is respectively connected by two pin shafts to form a fixed ring 1; the other end The two fixed rings 1 are connected by positioning connecting bolts 3; there is a gap at the half-ring port at the joint of the pin shaft, so that the two half-rings that are opened can be opened and closed around the pin shaft, so that the fixed ring 1 can be eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com