A method for fixing and welding movable pipelines in building construction

A technology for building construction and welding methods, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor fusion, insufficient strength, and incomplete penetration, so as to avoid welding obstacles, improve construction efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

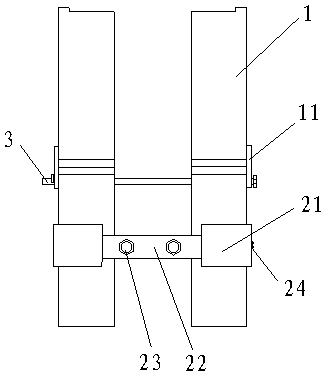

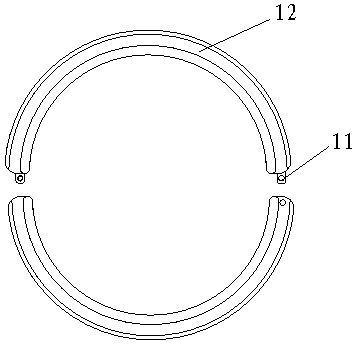

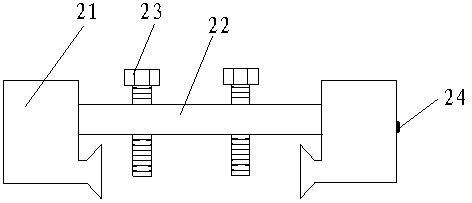

[0033] as attached Figure 1-5 Shown, a kind of pipeline fixed welding method in the construction of this patent, its specific steps are:

[0034] Step 1: Complete the processing of each component of the pipeline welding fixture, wherein the structure of each part is:

[0035] Two fixed rings 1: the structure includes two symmetrically arranged rings and two pin shafts; each fixed ring 1 is composed of two half-rings; connecting pieces 11 are provided on the outside of both ends of one of the half-rings , the connecting piece 11 is provided with a pin hole; the two ends of the other half ring are provided with the same pin hole as that of the connecting piece 11; one end of the two half rings is respectively connected by a pin to form a fixed ring 1; The other end connects the two fixed rings 1 through the positioning connecting bolt 3; a gap is also provided at the half-ring port at the joint of the pin shaft, so that the two half-rings can be opened and closed around the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com