Fan for motor and manufacturing method of fan

A manufacturing method and fan technology, applied in the direction of manufacturing tools, mechanical equipment, electric components, etc., to achieve firm connection, avoid collision and displacement, and good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In conjunction with the above-mentioned accompanying drawings, the motor fan of the present invention and its manufacturing method are described in detail:

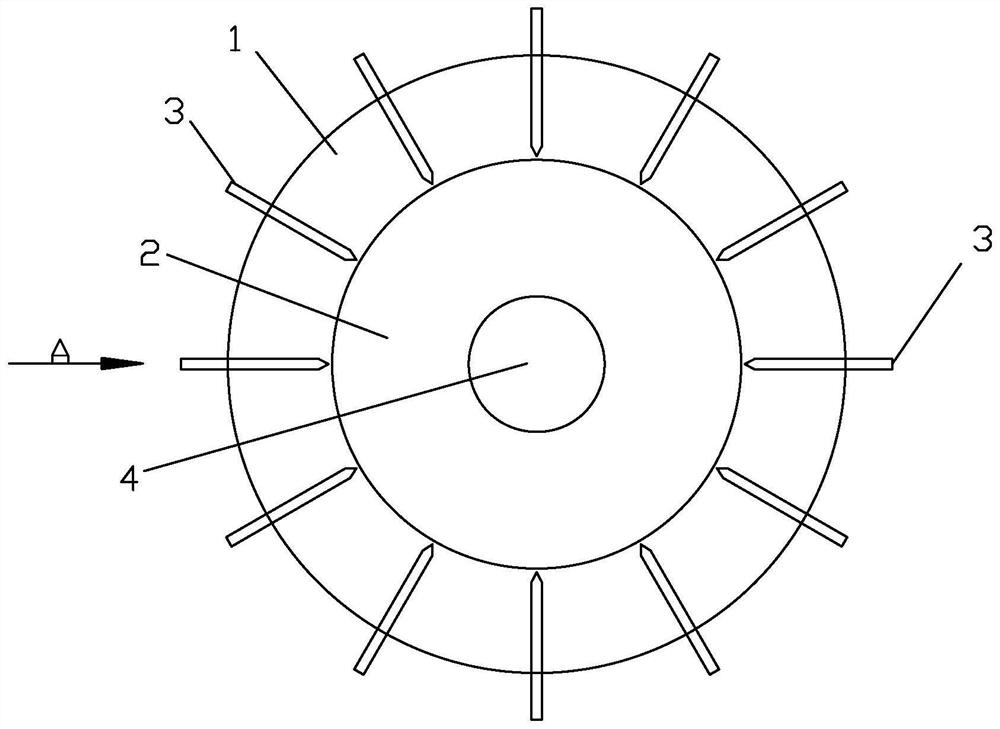

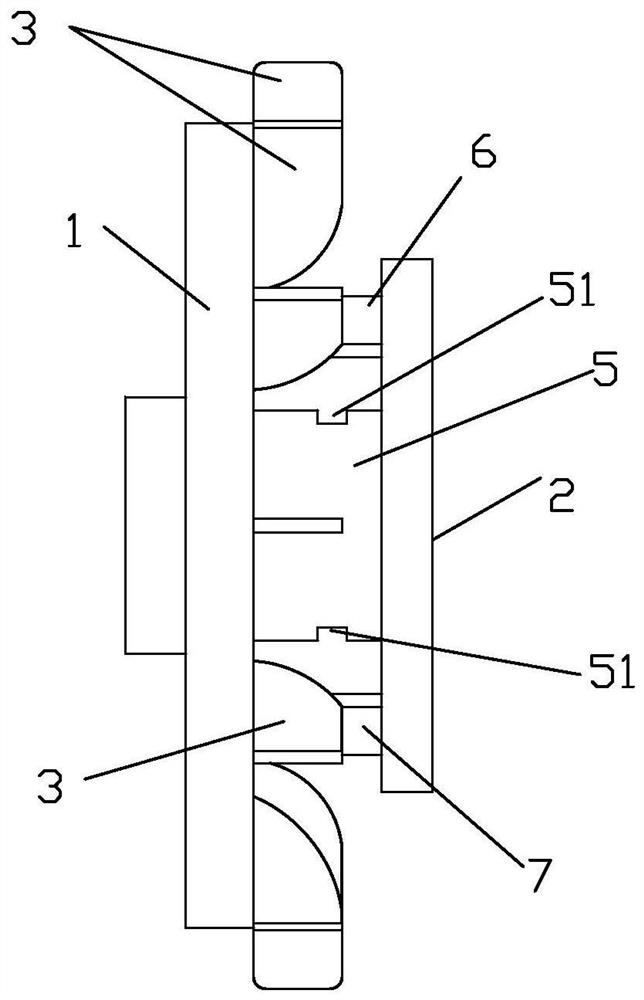

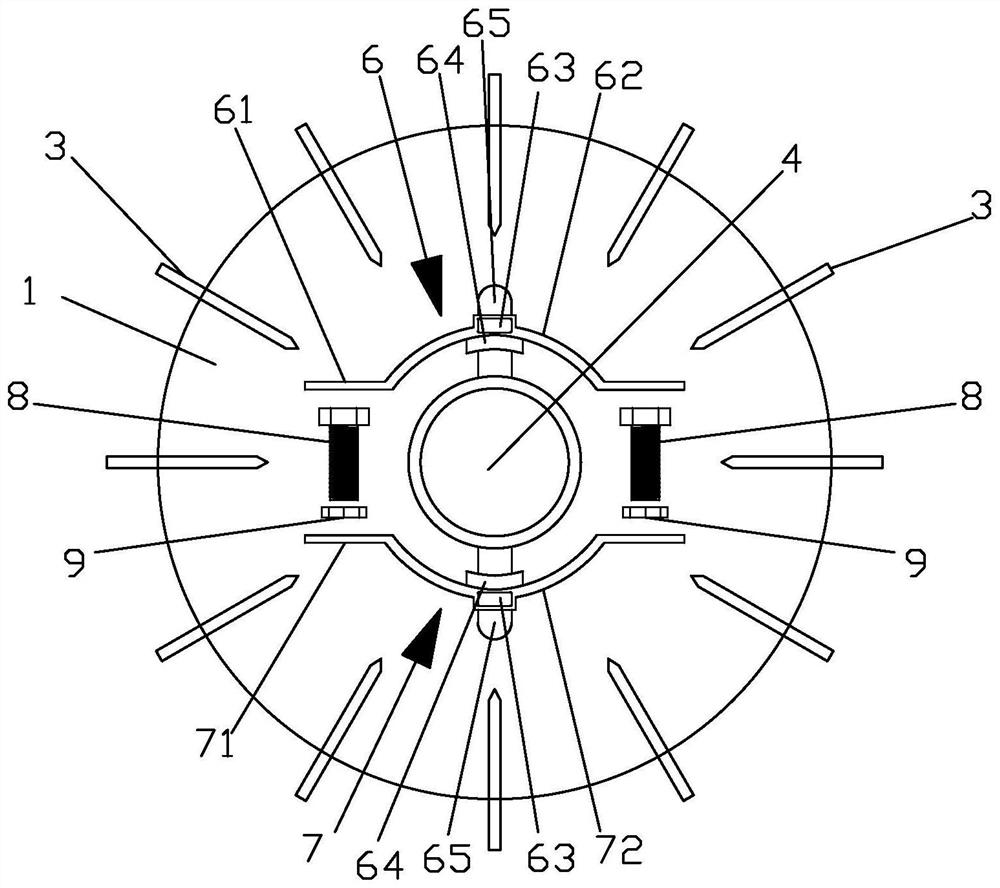

[0043] 1. Motor fan

[0044] Including the base plate 1, the reinforcement plate 2 and the fan blade 3 installed on the base plate 1, the reinforcement plate 2 is connected with the shaft tube 5, the shaft tube 5 is welded with the base plate 1, and the shaft hole 4 is formed, and the motor is connected through the shaft hole 4 shaft; a clamping hoop is provided between the base plate 1 and the reinforcing plate 2, the clamping hoop includes an upper hoop 6 and a lower hoop 7, the upper hoop 6 and the lower hoop 7 are respectively located at the two ends of the shaft cylinder 5, the upper hoop 6 and the lower hoop The hoop 7 is clamped and fixed by the bolt 8 and the nut 9; the upper hoop 6 and the inner side of the lower hoop 7 are equipped with a clamping block 64, and the shaft cylinder 5 is provided with a clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com