Wheel type mechanism of which radius can be adjusted

A radius adjustment and radius technology, applied in the directions of wheels, transportation and packaging, vehicle components, etc., can solve the problems of not changing the radius of the wheel body, bumps, etc., to reduce the sense of undulation and impact, ensure self-locking ability, and improve obstacle crossing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

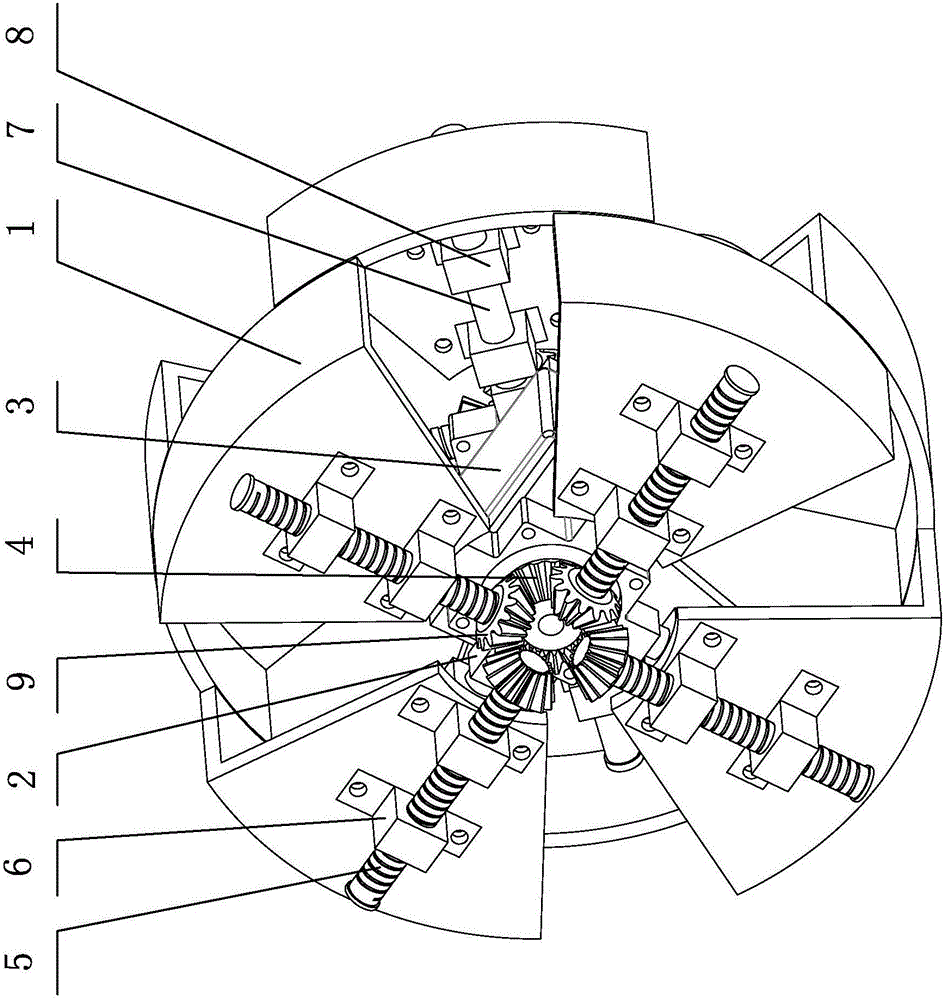

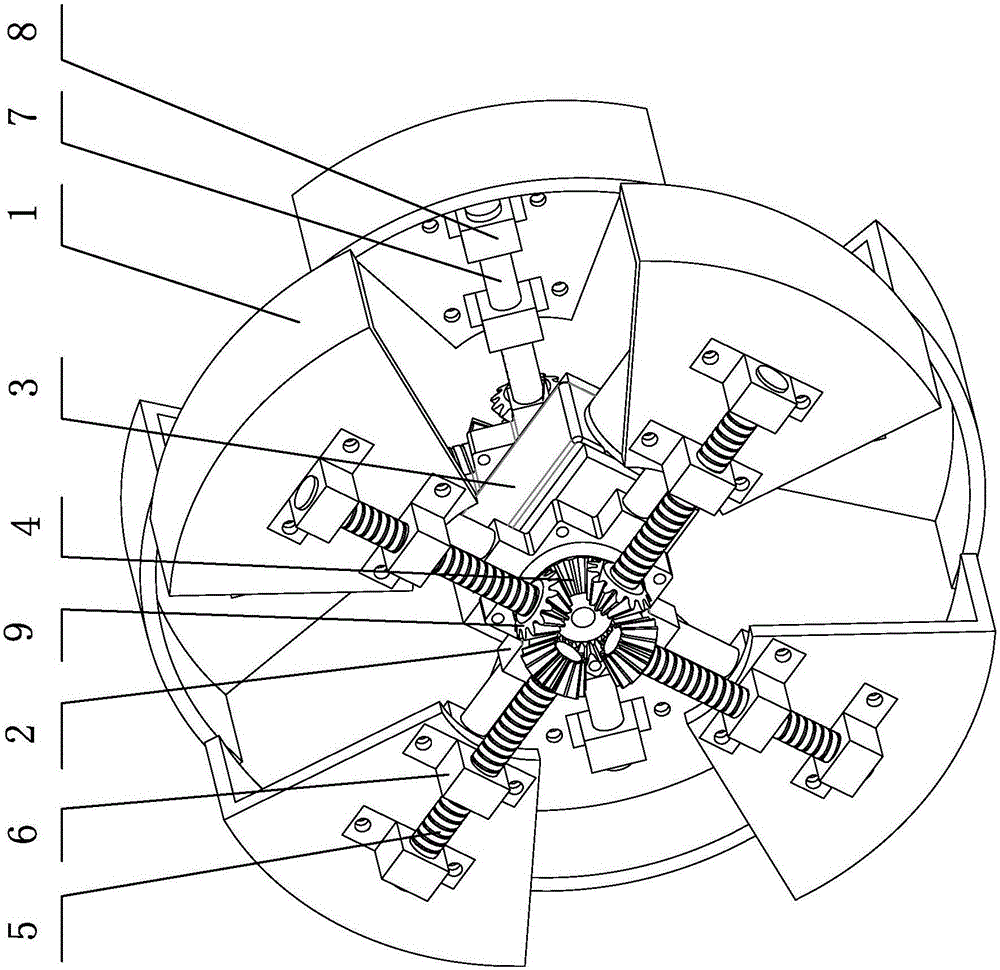

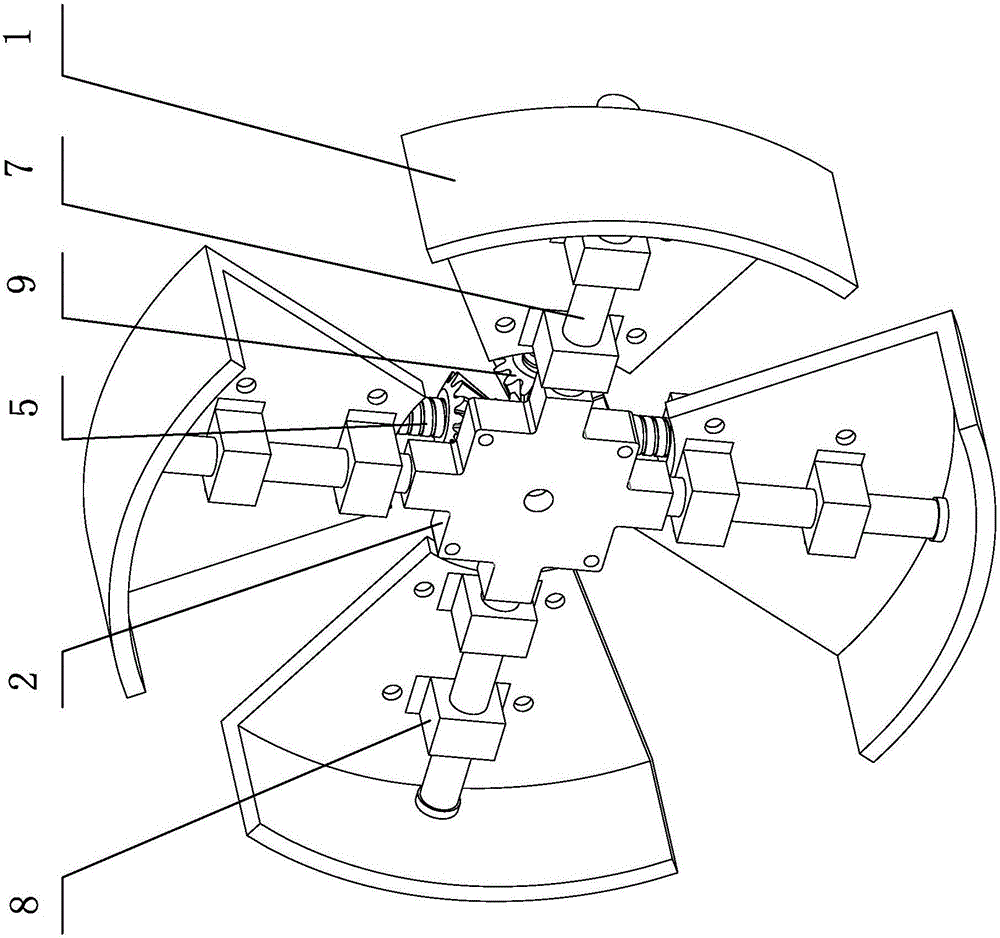

[0016] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0017] The technical solution of the radius-adjustable wheel mechanism of the present invention includes a wheel based on the wheel frame 2, a radius adjustment assembly and a motor drive assembly.

[0018] The wheel includes four spokes 1 on the left and right sides, and the four spokes 1 on each side are evenly distributed around the circumference. The spokes 1 include fan-shaped webs and arc-shaped rims. The other side is placed horizontally, and the spokes 1 on the left and right sides are at the same radial position and are opposite to each other with a 45° offset. ), that is, the two ends (circumferential direction) of the spoke 1 on one side overlap with the head and tail ends (circumferential direction) of the adjacent spoke 1 on the other side, and the distance between the overlapping rim end faces is 0. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com