Maintenance vehicle

A technology for repairing vehicles and hinged seats, which is applied in the direction of lifting devices, etc., can solve problems such as poor handling, and achieve the effect of convenient handling and maintenance, and a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

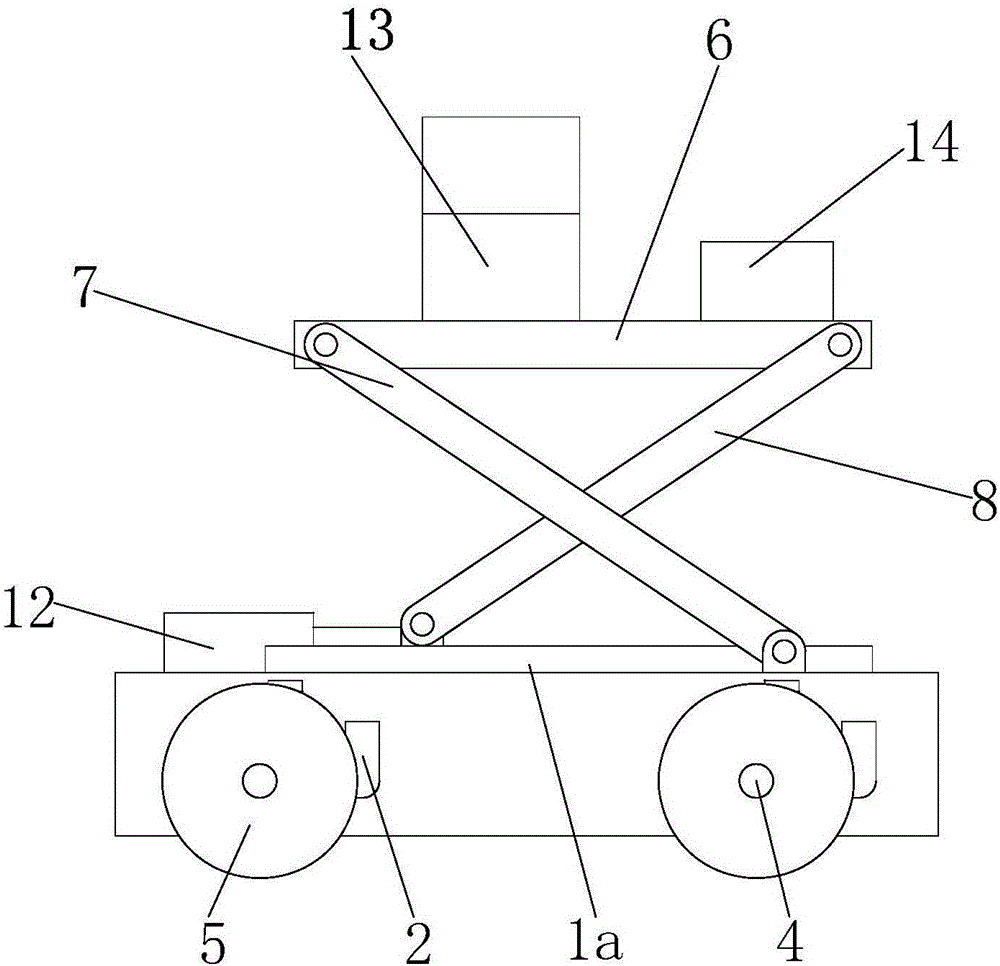

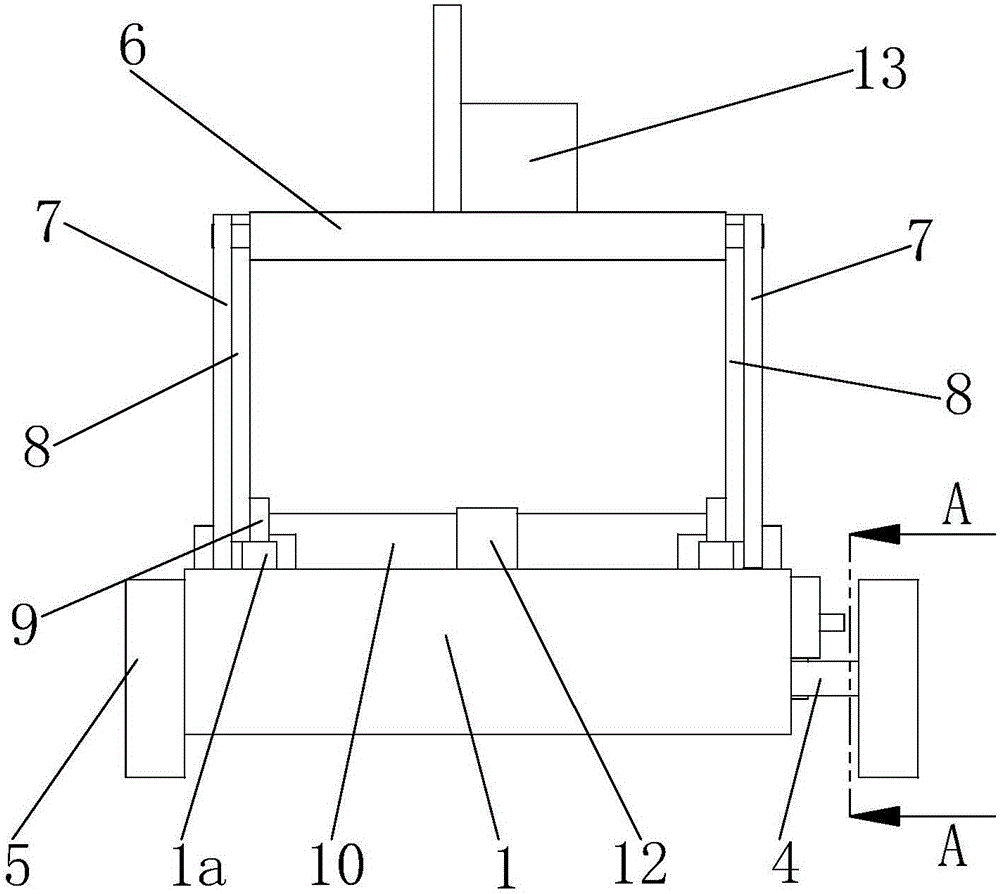

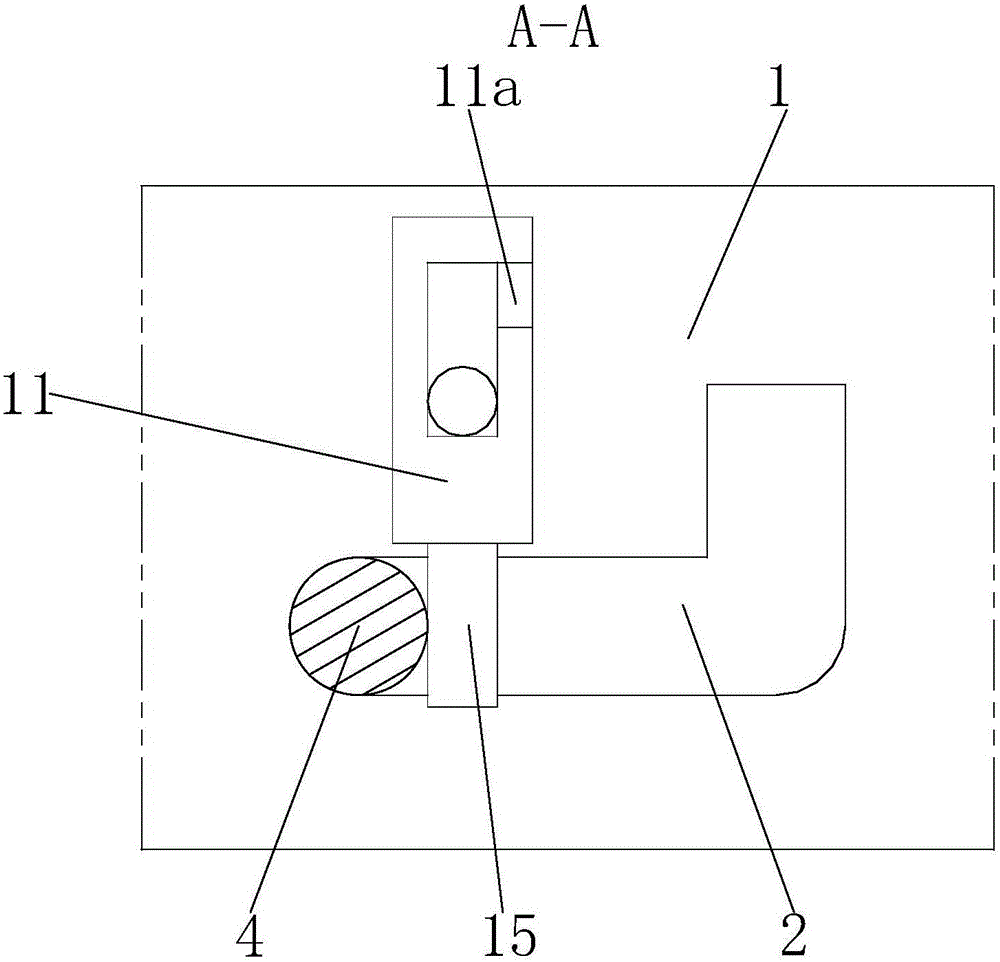

[0016] like Figure 1 to Figure 3 Shown, a kind of maintenance car, comprises vehicle base 1, and the front portion of described vehicle base 1, the rear portion are all provided with L-shaped holding tank 2, and above the middle part of described holding tank 2 all has track frame 11, described An L-shaped blocking pin 15 is slidably installed in the track frame 11 along the longitudinal direction, and a round roller 4 is slidably installed in the accommodating groove 2 , and wheels 5 are fixedly installed on the shaft ends of the round roller 4 .

[0017] There is a lifting platform 6 directly above the vehicle base 1, and an auxiliary strut 7 is hingedly connected to both of the lifting platform 6 and the vehicle base 1, and two active struts 8 are hinged at the lower end of the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com