X-shaped clothes hanger rotary connector and x-shaped clothes hanger prepared therefrom

A technology of rotating connectors and drying racks, which is applied in the field of drying racks, can solve the problems of broken separation, unfavorable carrying and moving, and large storage space of drying racks, so as to improve connection stability, facilitate carrying and moving, and reduce storage height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

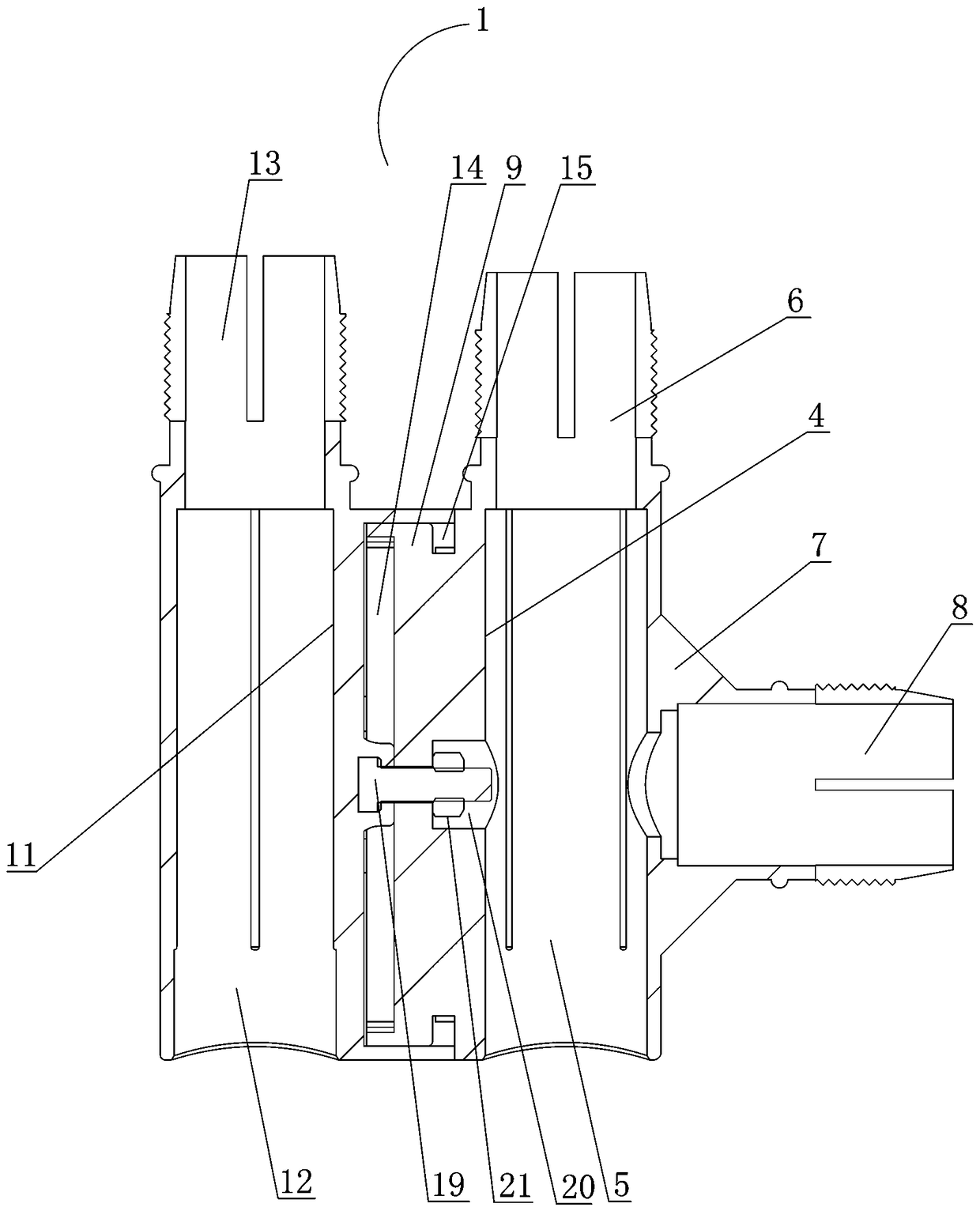

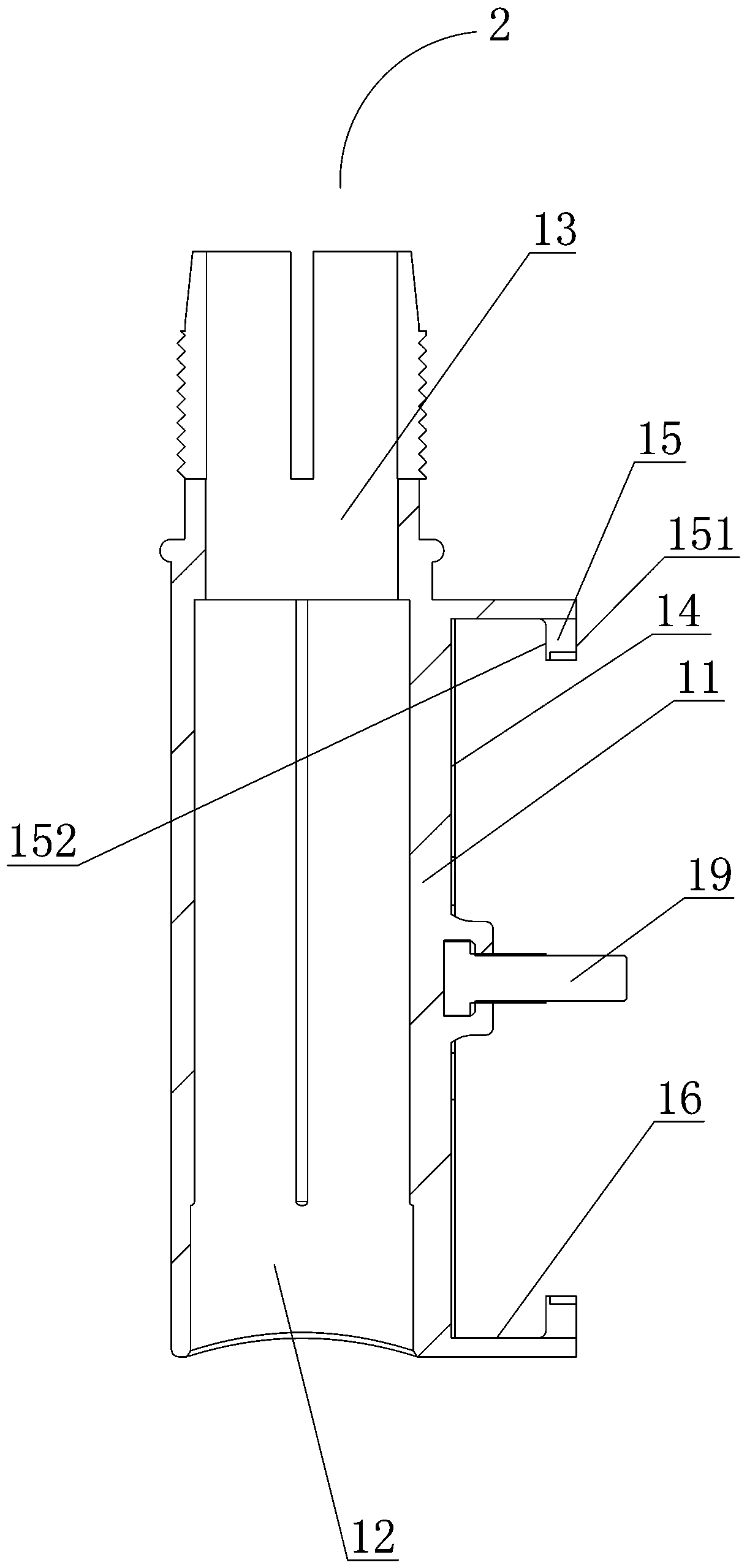

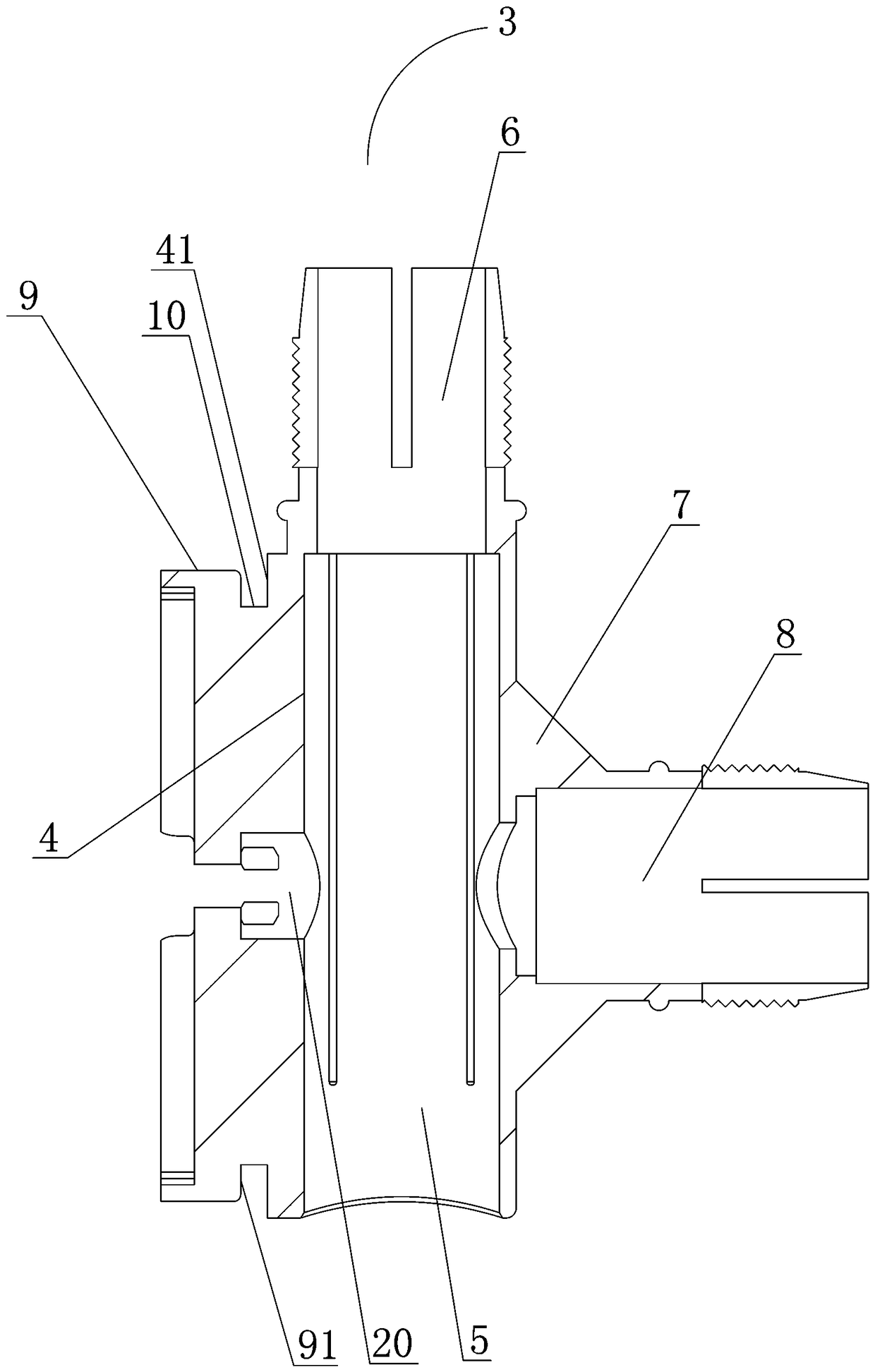

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the X-shaped clothes hanger rotating connector 1 includes an outer rotating member 2 and an inner rotating member 3 that are relatively rotatably connected. The outer side of the disk 4 is provided with an inner and lower support rod sleeve 5, and the upper end of the inner and lower support rod sleeve 5 is coaxially provided with a first locking sleeve 6, and a cross bar support sleeve 7 is arranged on the inner and lower support rod sleeve 5. The outer end of the cross-bar support sleeve 7 is coaxially provided with a second locking sleeve 8, and the inner side of the inner rotating disk 4 is provided with a limiting block 9, and a first clamp is formed between the limiting block 9 and the inner end surface of the inner rotating disk 4. Groove 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap