magnetic lock

A magnetic lock and lock body technology, applied in the field of door and window locks, can solve the problems of reducing the service life of the lock, damage to the user's body, wear and tear of the lock tongue and striker plate, etc., and achieve the effects of prolonging the service life, improving practicability, and facilitating unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

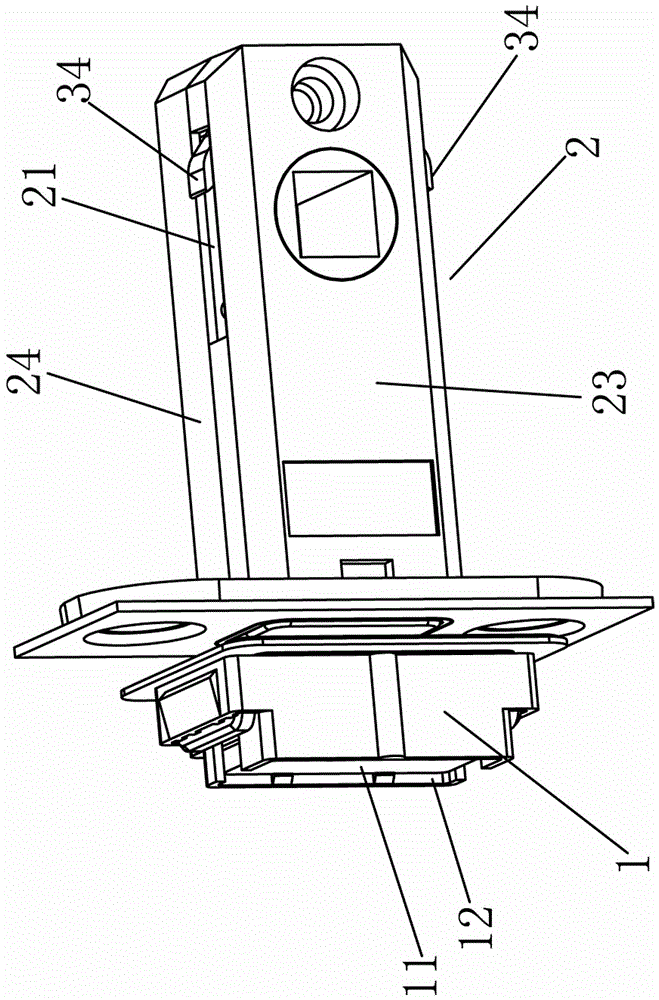

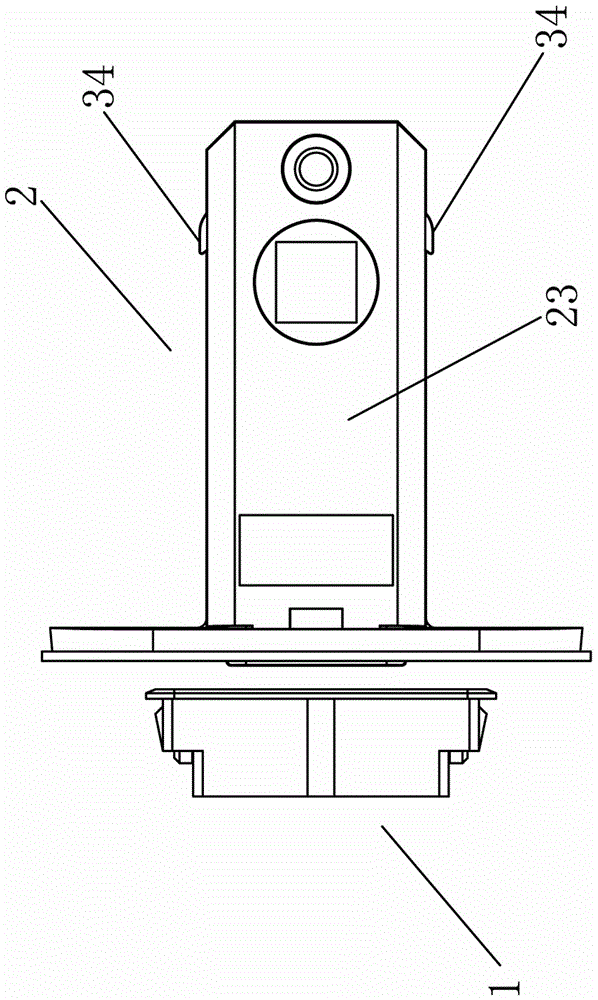

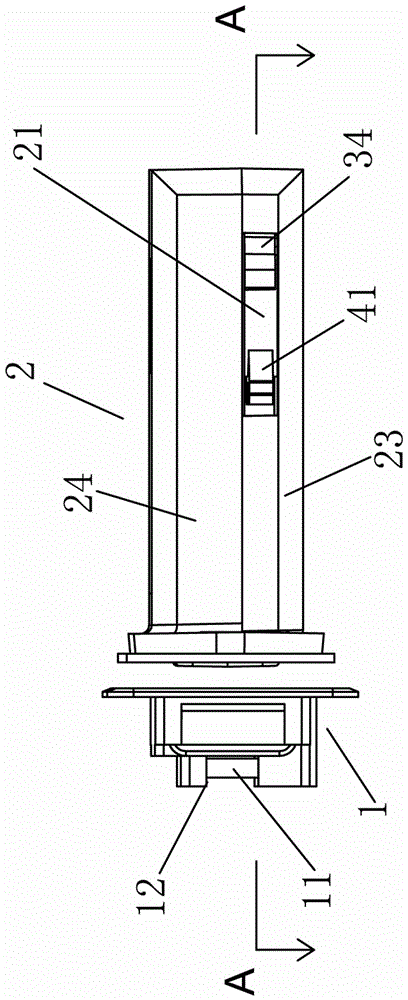

[0027] Example, combined with Figure 1 to Figure 8 As shown, a magnetic lock includes a striker plate 1, a lock body 2, a dead bolt 3 and a handle core 4, the striker plate 1 is installed on the door frame, and the bottom of the striker plate 1 is provided with a first magnet The accommodating cavity 12 , the first magnet 11 is locked in the first magnet accommodating cavity 12 .

[0028] The magnetic lock is installed on the door body corresponding to the position of the strike plate 1. The lock body 2 of the magnetic lock includes a cover 23 and a box body 24. The upper and lower side walls of the cover 23 are provided with chute 21, and the inner cavity of the box body 24 is A second magnet accommodating groove 25 is provided, and the second magnet 22 is clamped in the second magnet accommodating groove 25 , and the cover 23 and the box body 24 are buckled to form the lock body 2 .

[0029] The deadbolt 3 includes a deadbolt head 31 and two legs 32, the deadbolt head 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com