Stator screw hole position testing fixture

A technology of screw holes and inspection tools, applied in measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of stator performance and defective rate that have a great influence, and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

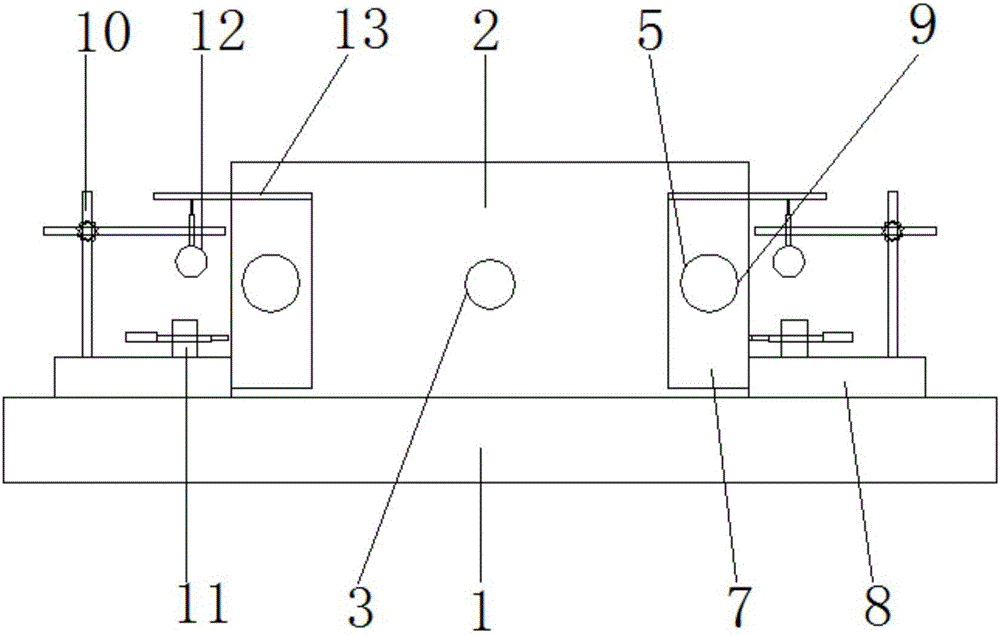

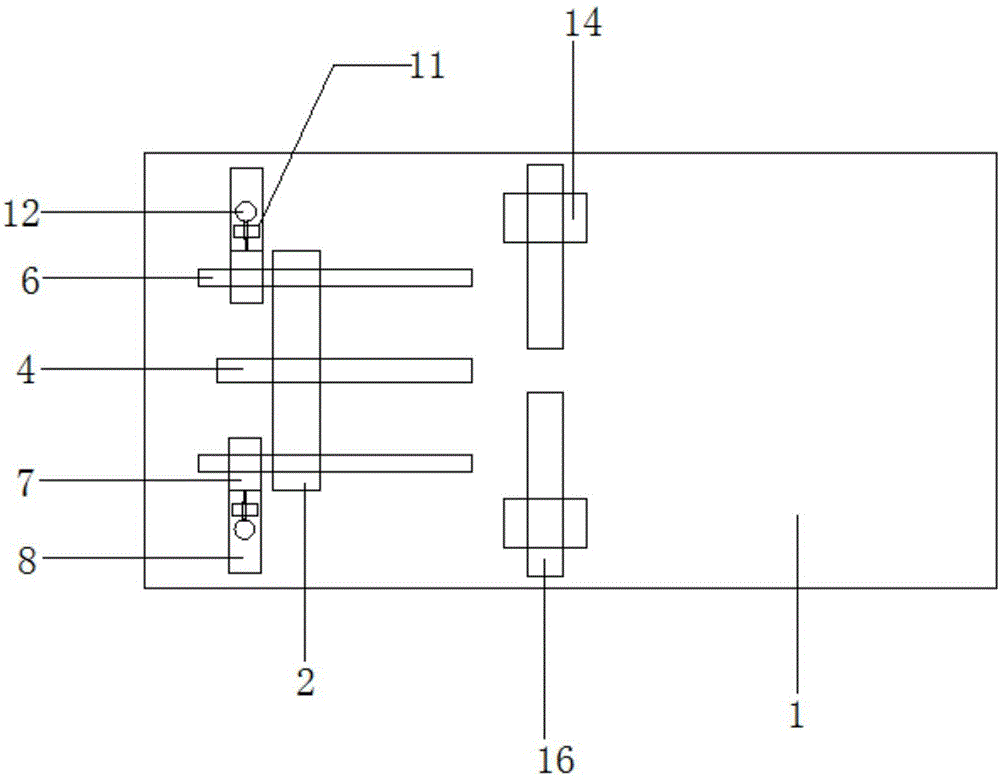

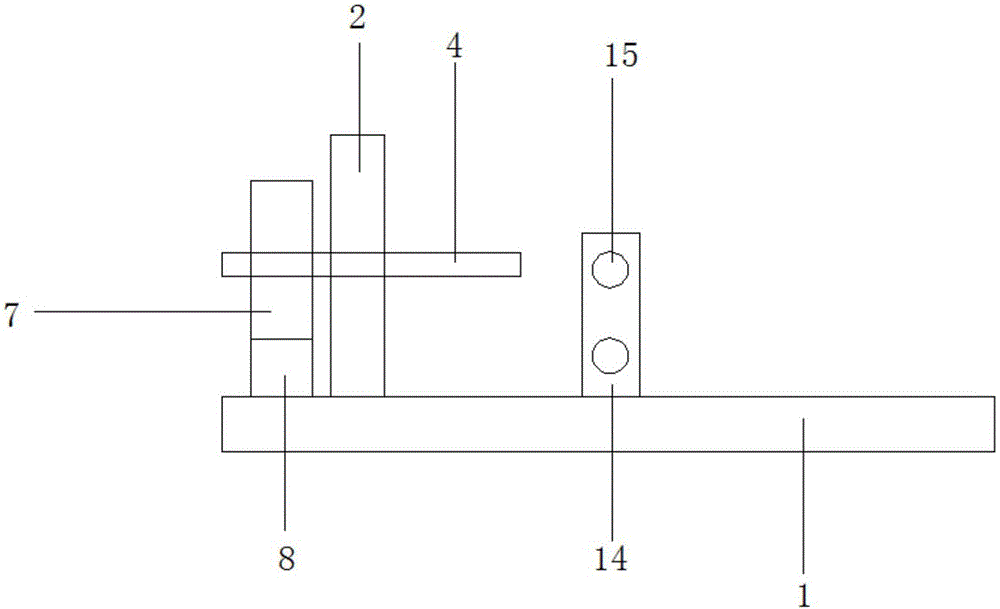

[0017] see Figure 1-3 , the present invention provides a technical solution: a stator screw hole position detector, including a base 1, a positioning seat 14 is installed in the middle of the base 1, a fixing pin hole 15 is opened on the positioning seat 14, and a fixing pin hole 15 is interspersed in the fixing pin hole 15. Pin 16, positioning seat 14 is provided with two, and each positioning seat 14 has two fixed pin holes 15 up and down, is all interspersed with a fixed pin 16 in each fixed pin hole 15, by four fixed pins 16 up and down front and back The stator to be determined is fixed on the base 1;

[0018] A detection board 2 is fixed on one side of the base 1, and a positioning pin hole 3 is opened in the middle of the detection board 2, and a positioning pin 4 is interspersed in the positioning pin hole 3, and the detection pin 4 is inserted into the screw hole in the middle of the tester for preliminary calibration Positioning, the detection board 2 has a first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com