A circuit breaker housing and a circuit breaker with the housing

A circuit breaker and casing technology is applied in the field of circuit breaker casings and circuit breakers with the casings, which can solve problems such as potential safety hazards of circuit breakers, achieve stable arc extinguishing performance, improve breaking capacity and use safety , the effect of improving segmentation capability and security performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

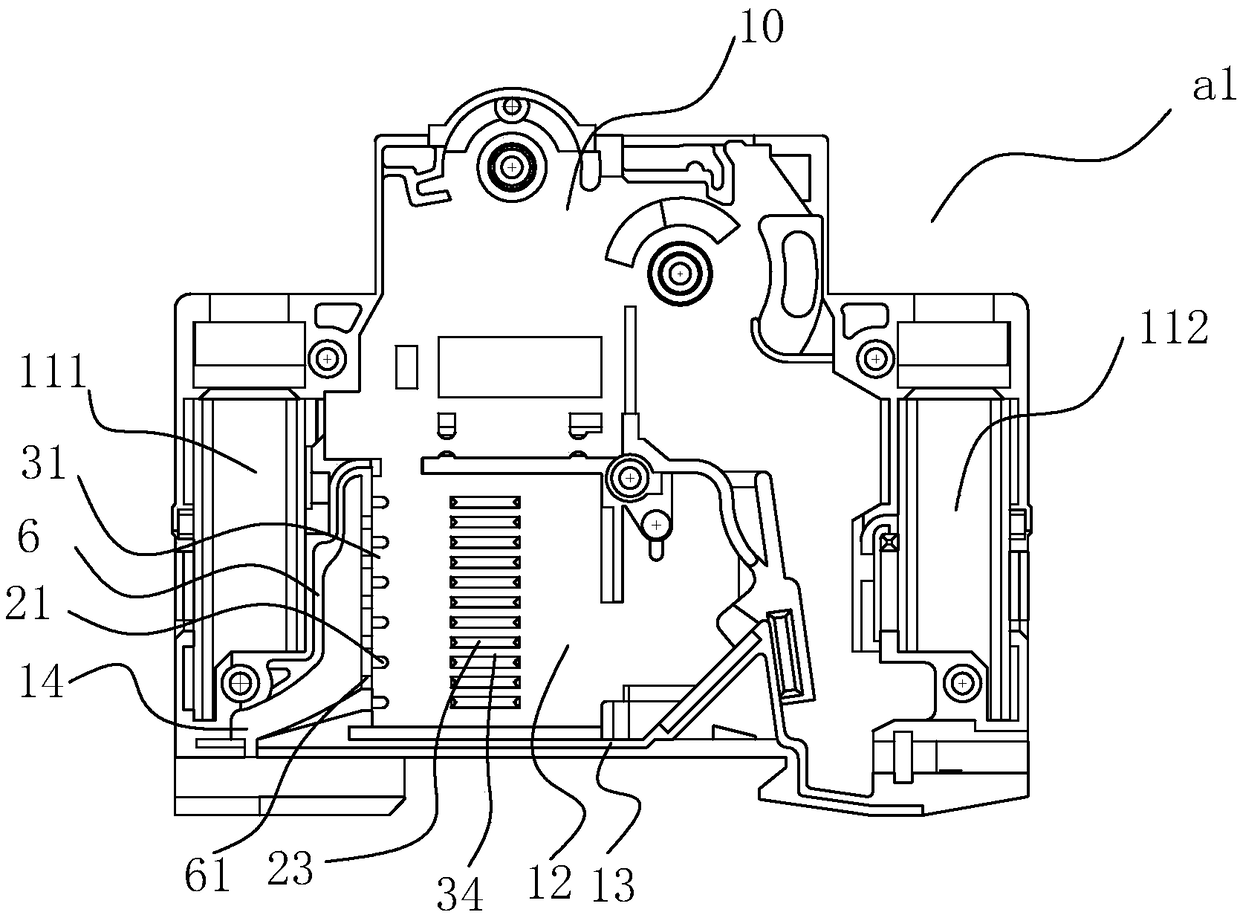

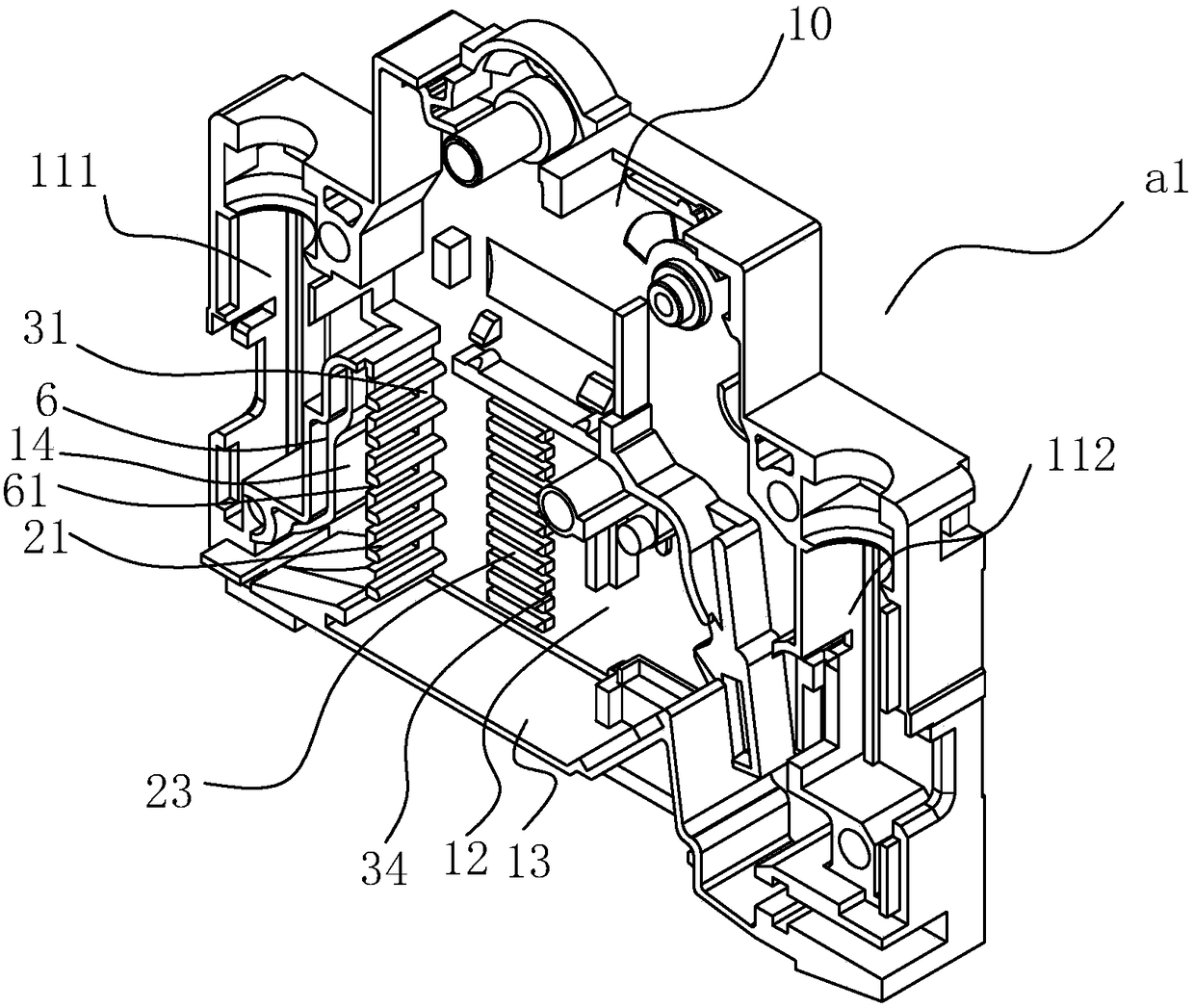

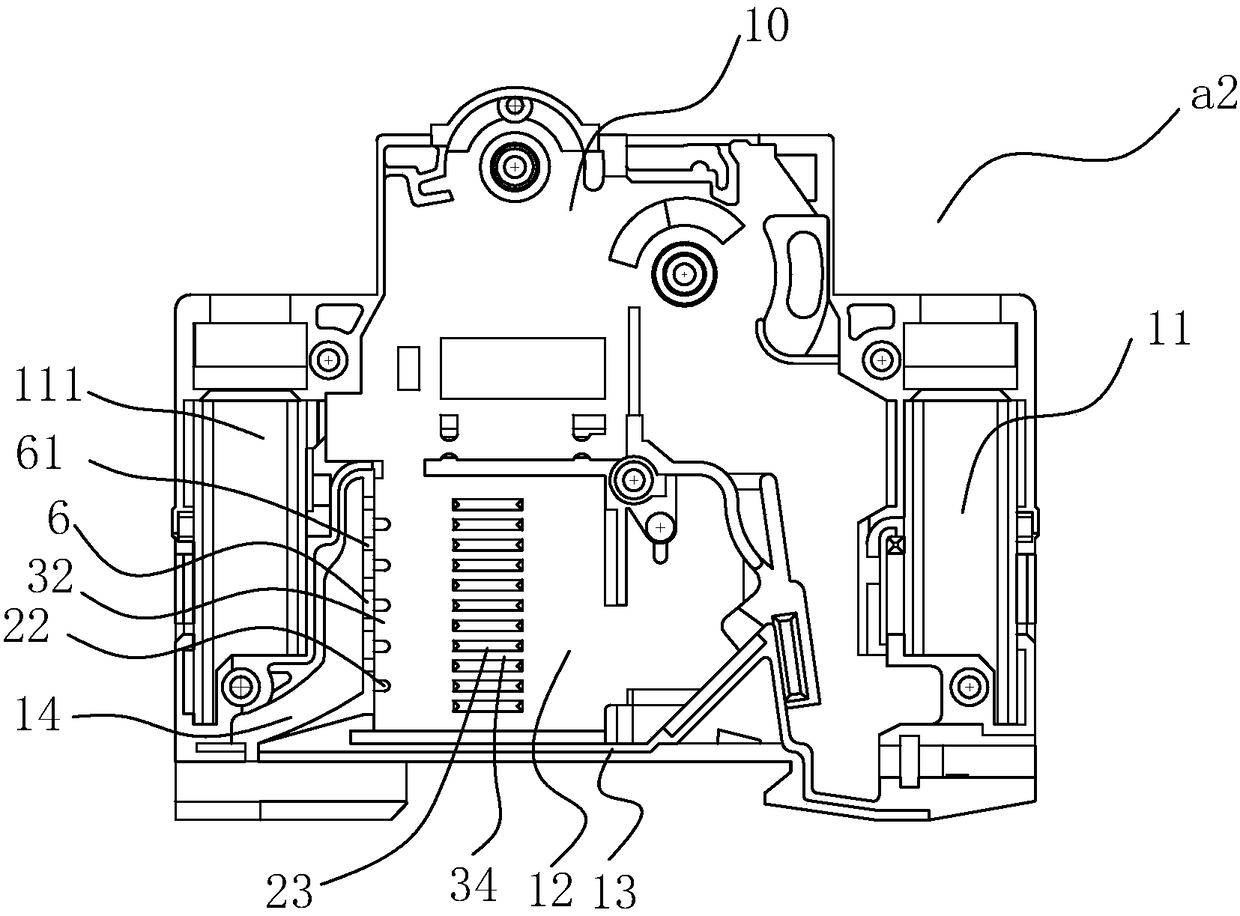

[0049] Such as Figure 1-3 Said, a circuit breaker housing includes a first housing a1 and a second housing a2 that have the same shape and size and constitute a complete circuit breaker housing, both of which form an operating mechanism housing area 10 and a wiring assembly housing Area, arc extinguishing chamber accommodation area 12, arc pilot accommodating area 13, and wall member 6, wall member 6, wall member 6 of the first shell a1 is surrounded by at least one ventilation channel 14, and wall of the second shell a2 At least one vent passage 14 is formed around the member 6, and the wall members 6 of both are provided with an arc inlet 61 connecting the vent passage 14 and the arc extinguishing chamber containing area 12.

[0050] Such as figure 1 , figure 2 As shown, the first housing a1 is integrally formed with several main anti-breakdown protrusions 21, and a main arc extinguishing grid positioning gap 31 is formed between every two adjacent main anti-breakdown protrusi...

Embodiment 2

[0055] The difference from Embodiment 1 is that the circuit breaker housing is not divided into two parts, but is integrally formed using 3D printing technology, that is, the arc extinguishing grid positioning protrusion 23 and the second housing a2 are integrated.

Embodiment 3

[0057] The difference from Embodiment 1 is that the primary anti-breakdown protrusions 21 and the secondary anti-breakdown protrusions 22 are arranged in parallel, that is, the height of the main arc extinguishing grid positioning gap 31 = the secondary arc extinguishing grid positioning gap 32 height = the secondary arc extinguishing Grid positioning gap 33 = height of actual arc extinguishing grid positioning gap 34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com