Electric vehicle main power switch

A technology for electric vehicles and total power supply, applied in electromagnetic relays, detailed information of electromagnetic relays, circuits, etc., can solve problems such as unusable main power switches, and achieve the effect of preventing deformation and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

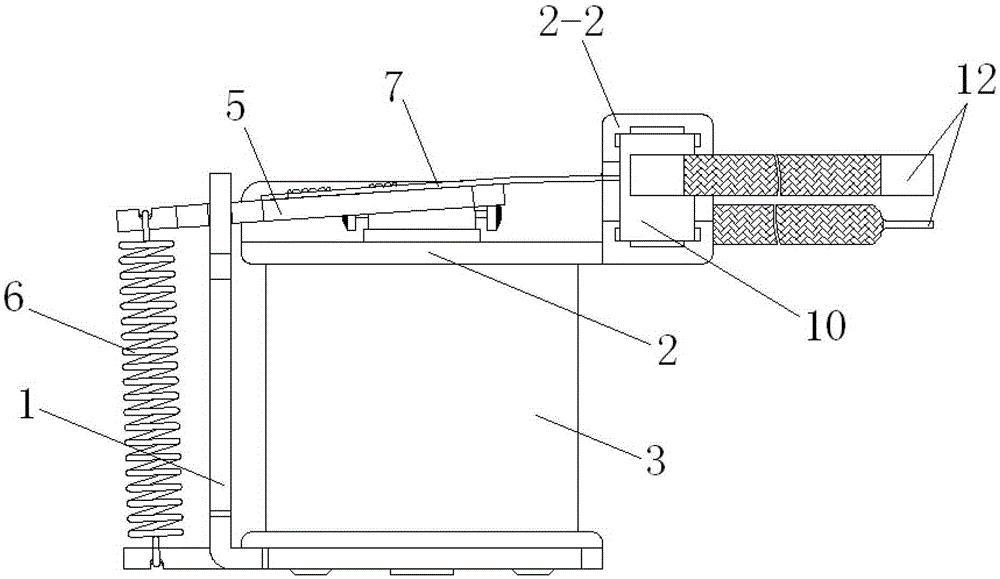

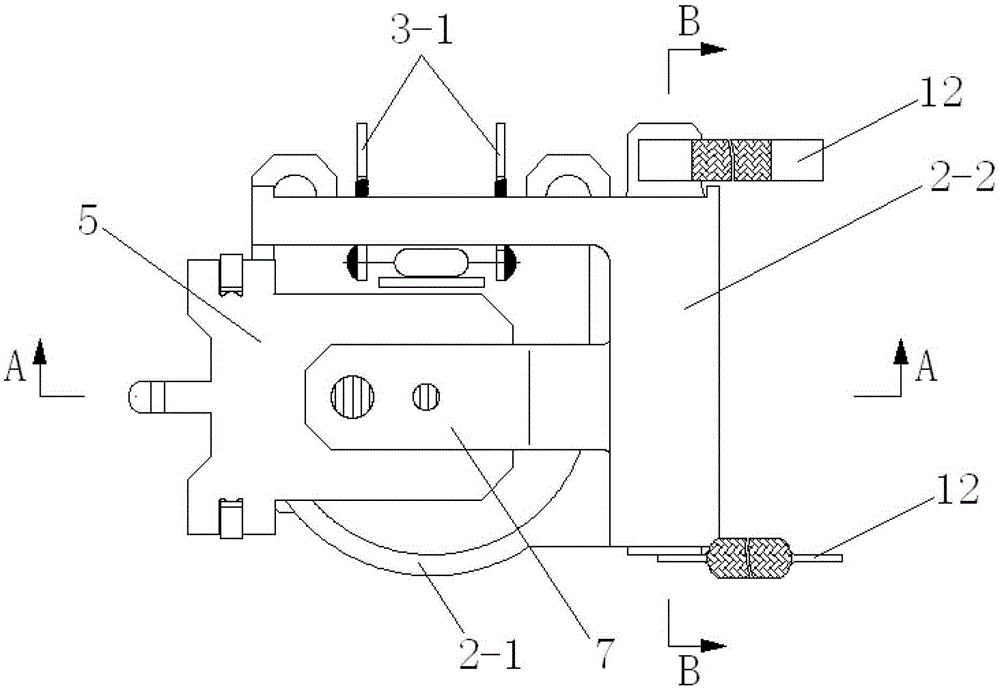

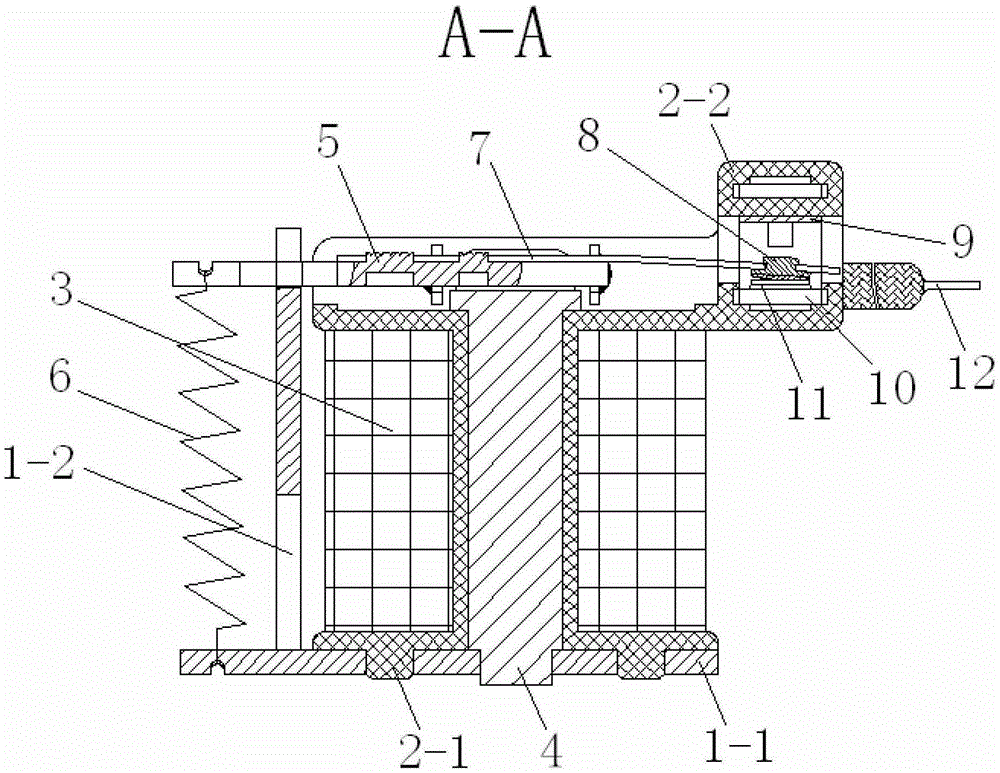

[0035] The electric vehicle total power switch of the present embodiment comprises yoke iron 1, bobbin 2, coil 3, iron core 4, armature 5, extension spring 6, moving reed 7, moving contact 8, supporting piece 9, static reed 10. Static contacts 11, brush wires 12 and insulating materials.

[0036] The yoke 1 includes a horizontal portion 1-1 disposed horizontally and a vertical portion 1-2 disposed vertically. The coil bobbin 2 is fixed on the horizontal part 1-1 of the yoke 1, and the coil bobbin 2 includes a coil installation part 2-1 and a contact installation part 2-2. The coil 3 is wound on the coil installation part 2 - 1 of the coil bobbin 2 , and the two lead-out terminals 3 - 1 of the coil 3 are fixed on the coil installation part 2 - 1 of the coil bobbin 2 . The power consumption of the coil 3 is ≤5.5W. The iron core 4 is fixed at the center of the coil installation part 2 - 1 of the bobbin 2 . The middle part of the armature 5 is supported by the vertical part 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com