Opening speed improved superhigh-voltage silicon carbide thyristor and manufacturing method thereof

A technology of silicon carbide crystal and silicon carbide, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of limited improvement of turn-on time, increase the complexity of test circuits, etc., and achieve the effect of increased turn-on speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

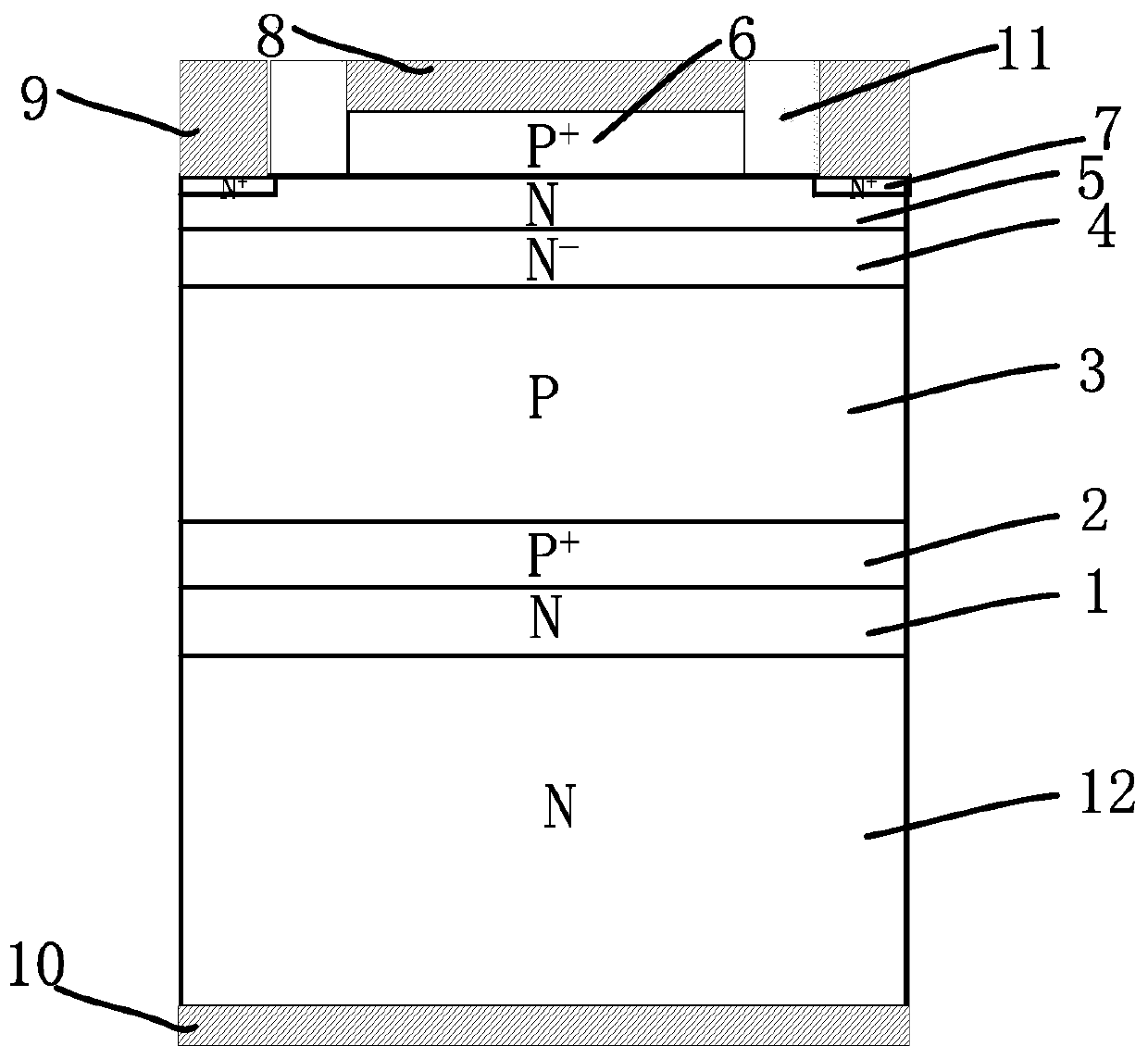

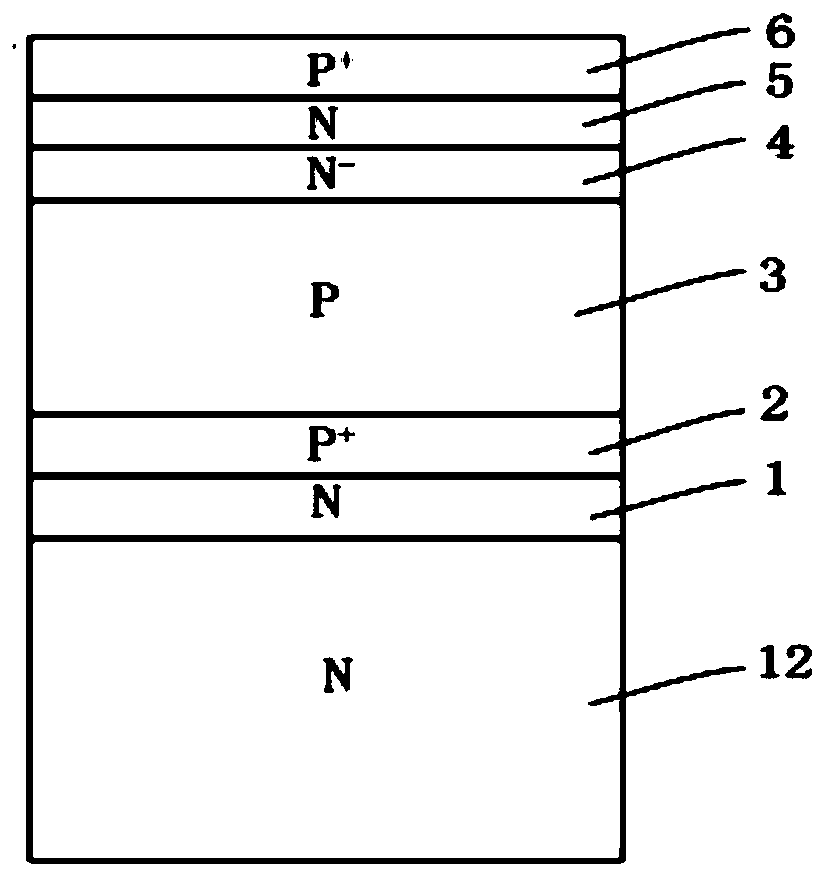

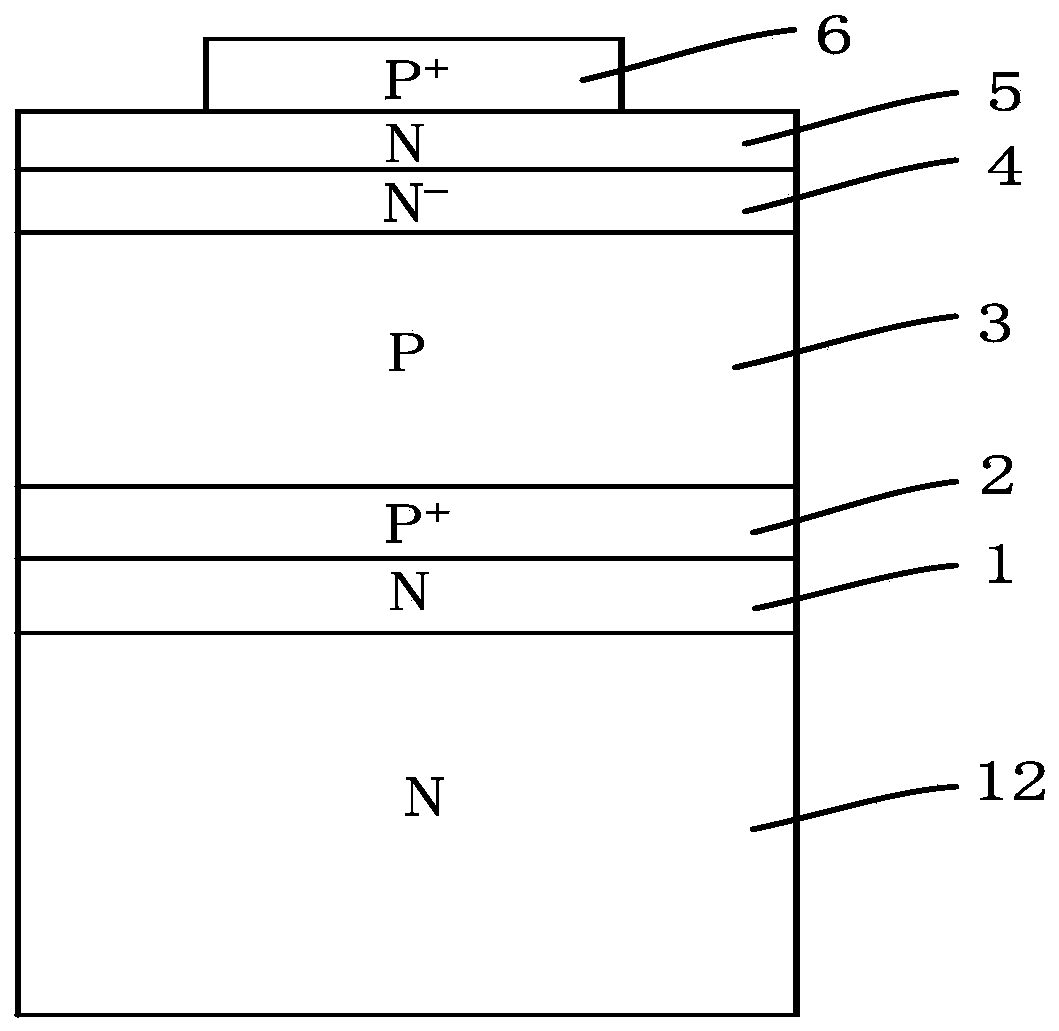

[0061] Step 1. First select a 4H-SiC single crystal substrate, and then epitaxially grow silicon carbide N buffer layer 1, silicon carbide P+ buffer layer 2, silicon carbide P long base region 3, and silicon carbide N- low-doped silicon carbide substrate on the substrate surface. Region 4, silicon carbide N highly doped region 5 and silicon carbide P+ emitter region 6, the thickness of the 4H-SiC single crystal substrate is 300-350 μm;

[0062] The doping concentration of silicon carbide N buffer layer 1 is 2x10 18 cm -3 , the thickness of SiC N buffer layer 1 is 1.0 μm, and the doping concentration of SiC P+ buffer layer 2 is 2x10 17 cm -3 , the thickness of the silicon carbide P+ buffer layer 2 is 2.0 μm, and the doping concentration of the silicon carbide P long base region 3 is 2×10 14 cm -3 , the thickness of the silicon carbide P long base region 3 is 160 μm, and the doping concentration of the silicon carbide N-lowly doped region 4 is 2×10 14 cm -3 , the thickness o...

Embodiment 2

[0071] Step 1. First select a 6H-SiC single crystal substrate, and then epitaxially grow silicon carbide N buffer layer 1, silicon carbide P+ buffer layer 2, silicon carbide P long base region 3, and silicon carbide N- low-doped silicon carbide substrate on the substrate surface. Region 4, silicon carbide N highly doped region 5 and silicon carbide P+ emitter region 6, the thickness of the 4H-SiC single crystal substrate is 320 μm;

[0072] The doping concentration of silicon carbide N buffer layer 1 is 2x10 18 cm -3 , the thickness of SiC N buffer layer 1 is 1.0 μm, and the doping concentration of SiC P+ buffer layer 2 is 2.5x10 17 cm -3 , the thickness of the silicon carbide P+ buffer layer 2 is 2.2 μm, and the doping concentration of the silicon carbide P long base region 3 is 2.x10 14 cm -3 , the thickness of the silicon carbide P long base region 3 is 161 μm, and the doping concentration of the silicon carbide N-lowly doped region 4 is 2.5×10 14 cm -3 , the thicknes...

Embodiment 3

[0081] Step 1. First select a 4H-SiC single crystal substrate, and then epitaxially grow silicon carbide N buffer layer 1, silicon carbide P+ buffer layer 2, silicon carbide P long base region 3, and silicon carbide N- low-doped silicon carbide substrate on the substrate surface. Region 4, silicon carbide N highly doped region 5 and silicon carbide P+ emitter region 6, the thickness of the 4H-SiC single crystal substrate is 330 μm;

[0082] The doping concentration of silicon carbide N buffer layer 1 is 3x10 18 cm -3 , the thickness of SiC N buffer layer 1 is 1.2 μm, and the doping concentration of SiC P+ buffer layer 2 is 3x10 17 cm -3 , the thickness of the silicon carbide P+ buffer layer 2 is 2.5 μm, and the doping concentration of the silicon carbide P long base region 3 is 1.4×10 14 cm -3 , the thickness of the silicon carbide P long base region 3 is 163 μm, and the doping concentration of the silicon carbide N-lowly doped region 4 is 3×10 14 cm -3 , the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com