Vibration disc position adjusting device applicable to thread rolling machine

An adjustment device and vibration plate technology, applied in the mechanical field, can solve the problems of inability to adjust the position of the vibration plate, inconvenient installation of the vibration plate and the feeding mechanism, and low degree of automation, and achieve the effects of simple structure, convenient installation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

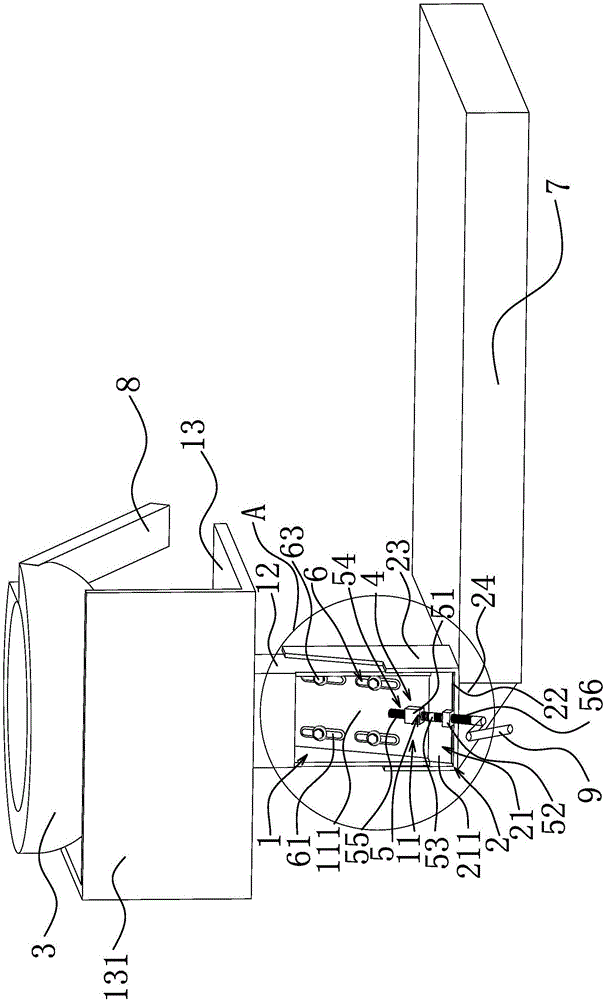

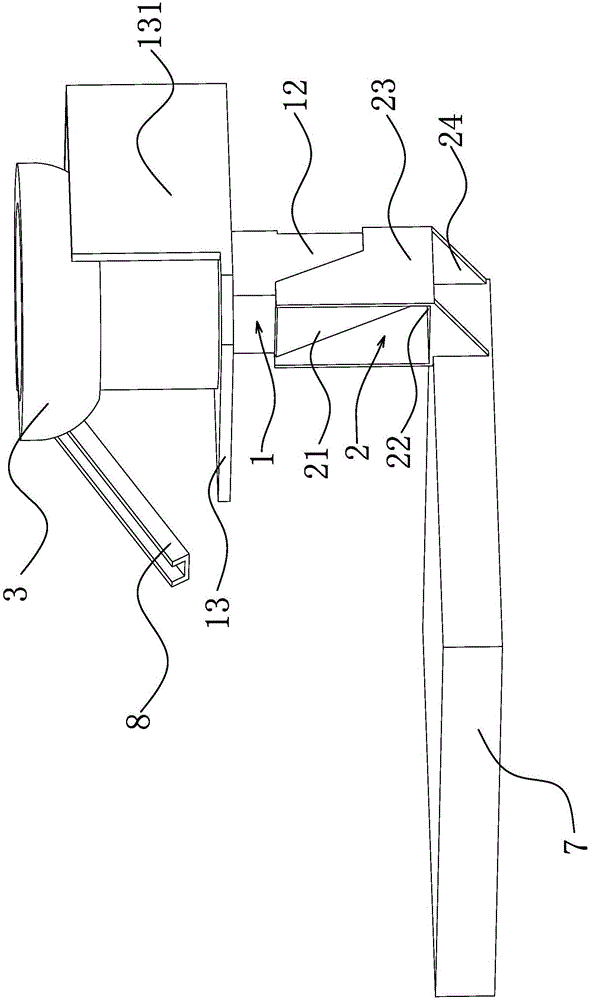

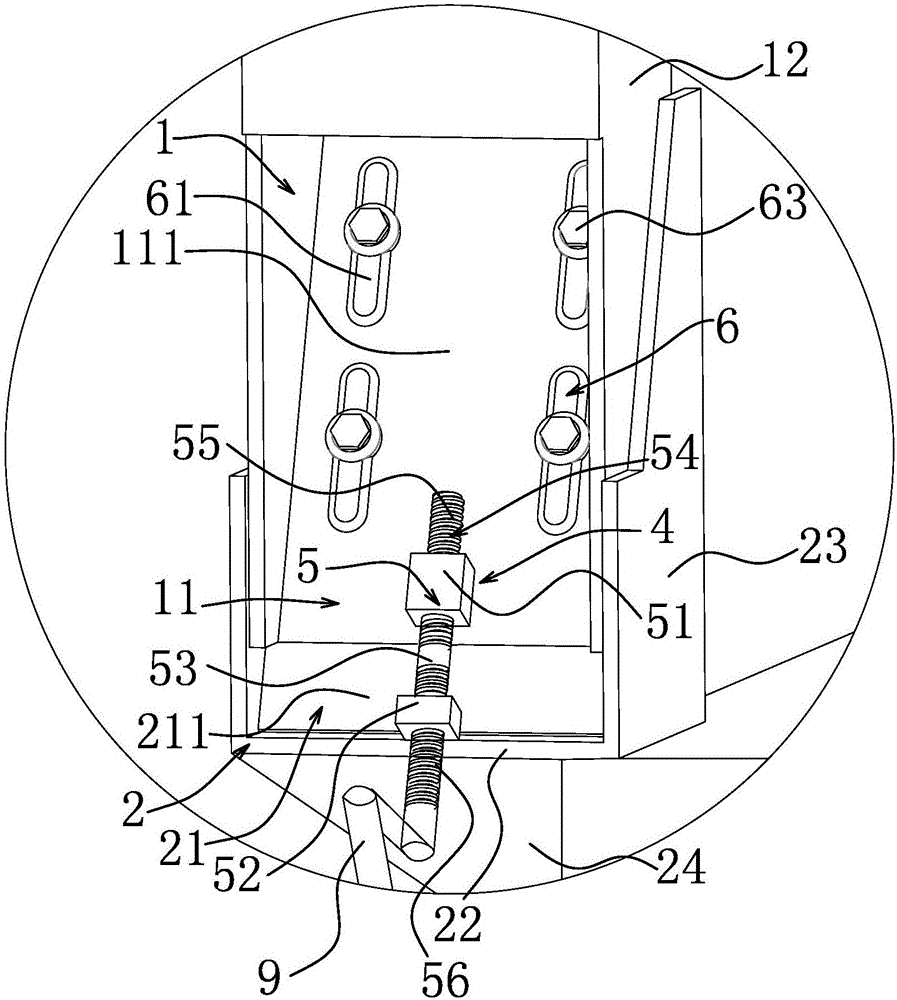

[0021] Such as figure 1 As shown in Figure 3, this device is applicable to the vibration plate position adjustment device of the thread rolling machine. This position adjustment mechanism includes an upper frame body 1 connected with the vibration plate body 3. The lower end of the upper frame body 1 is provided with an upper inclined surface 111 extending downward. The upper inclined plate 11, the lower end of the upper frame body 1 is movably connected with the lower frame body 2, the upper end of the lower frame body 2 is provided with a lower inclined plate 21 extending upwardly and corresponding to the lower inclined surface 211 corresponding to the upper inclined surface 111, and the upper inclined plate 11 It is slidingly connected with the lower sloping plate 21, and there is a device between the upper sloping plate 11 and the lower sloping plate 21 to enable the lower sloping plate 21 to have an upward thrust on the upper sloping plate 11, and the upper sloping plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com