Press fit jig

A technology of pressing jig and pressing mechanism, which is applied in the field of jig, can solve the problems of low efficiency, low assembly accuracy, unable to meet the requirements, etc., and achieve the effect of good pressing effect, improving quality and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

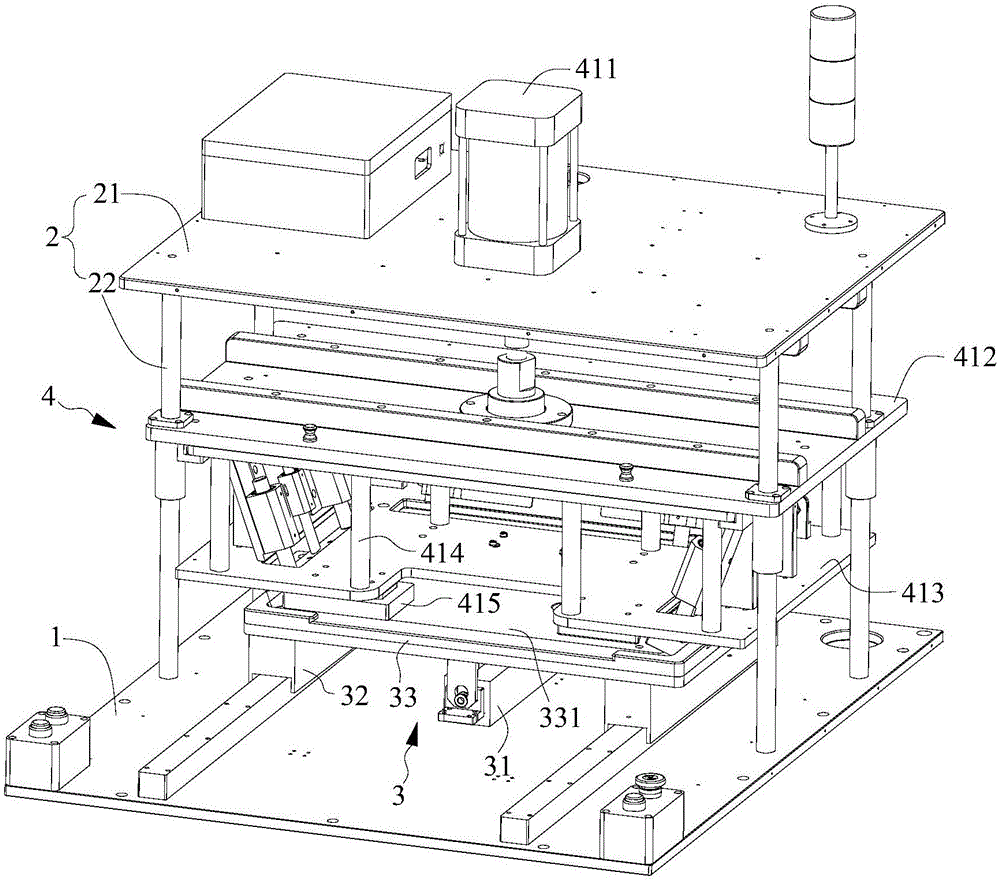

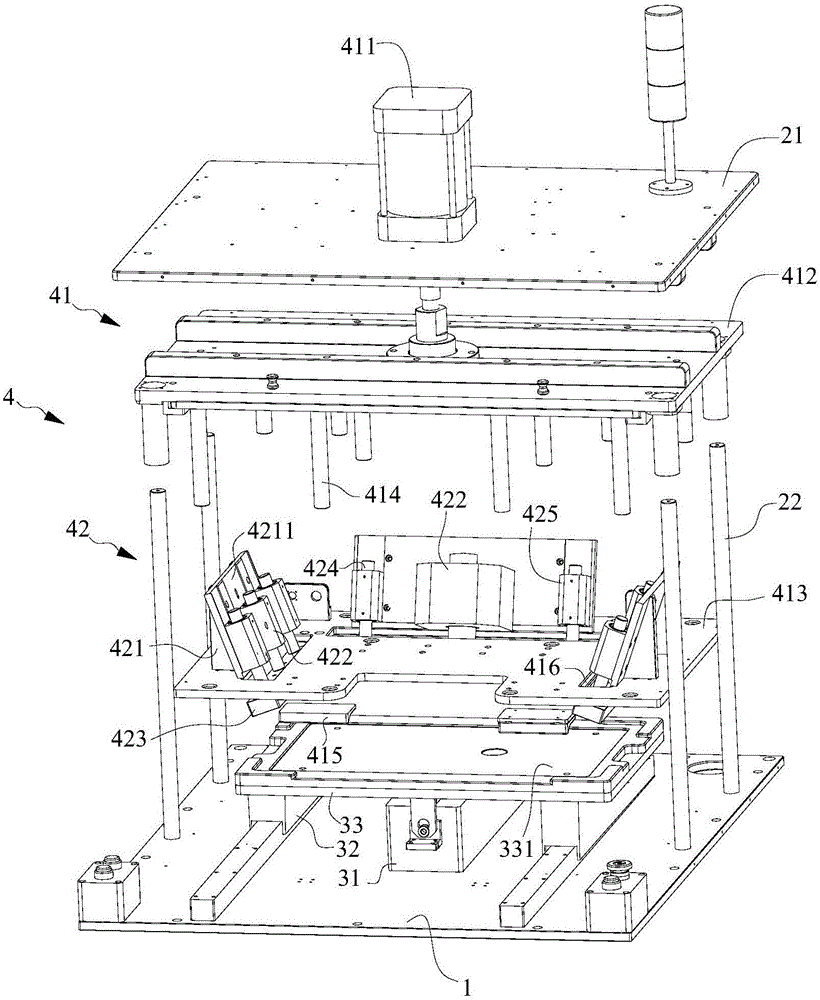

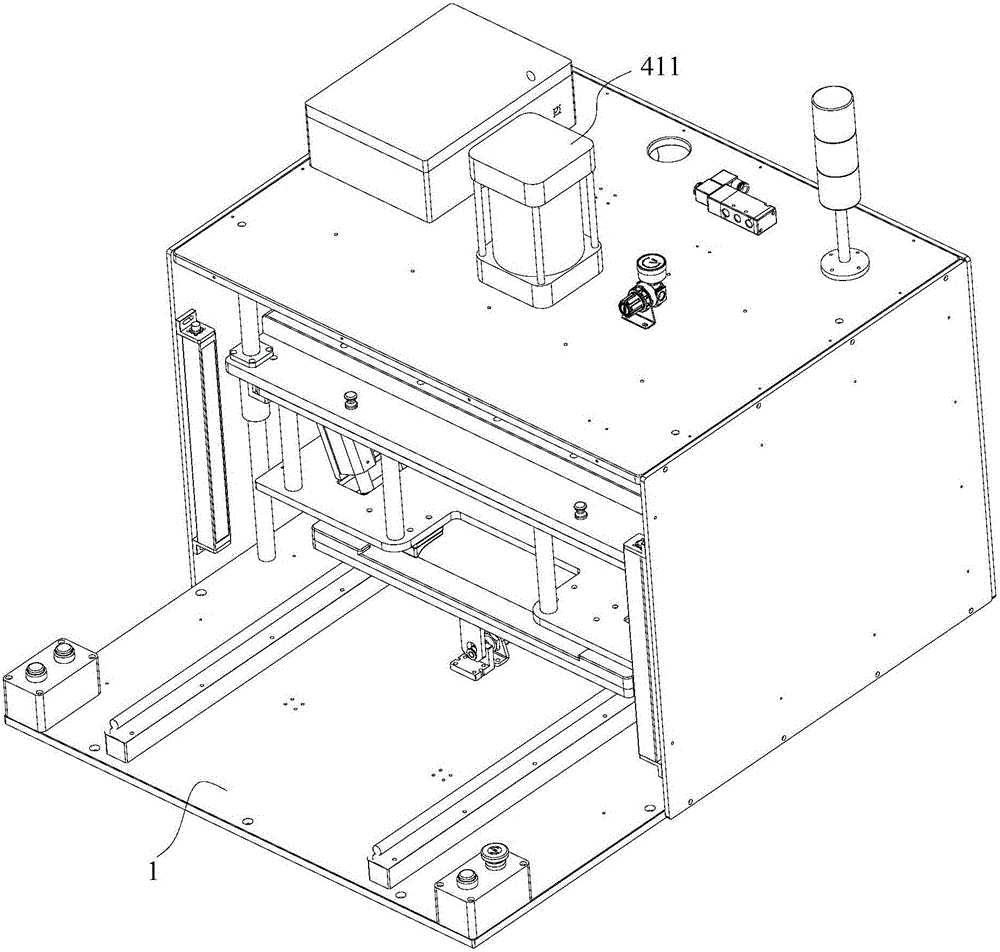

[0023] refer to Figure 1 to Figure 3 , this embodiment provides a pressing fixture, including a base 1, a supporting structure 2, a carrier module 3 and a pressing mechanism 4, the supporting structure 2 is fixed on the base 1, and the bottom of the carrier module 3 is slidable The ground is connected to the base 1, and the top is provided with a limit groove 331 for placing parts to be pressed. The pressing mechanism 4 includes a pressing mechanism 41 and a side pressing mechanism 42. The pressing mechanism 41 is arranged above the carrier module 3, and the side pressing mechanism 4 The pressing mechanism 42 is arranged on the pressing mechanism 41. The pressing mechanism 41 vertically presses down the back side of the component to be pressed from the top, and the side pressing mechanism 42 obliquely presses down the side of the component to be pressed. Through the pressing mechanism 41 and the side pressing mechanism 42, the parts to be pressed can be pressed vertically dow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap