Large-span two-arch two-cable subway station structure constructed through open-cut method

A subway station, large-span technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of long construction period, channel depression, increased strength loss, etc., to improve service life, clear force Reasonable and weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

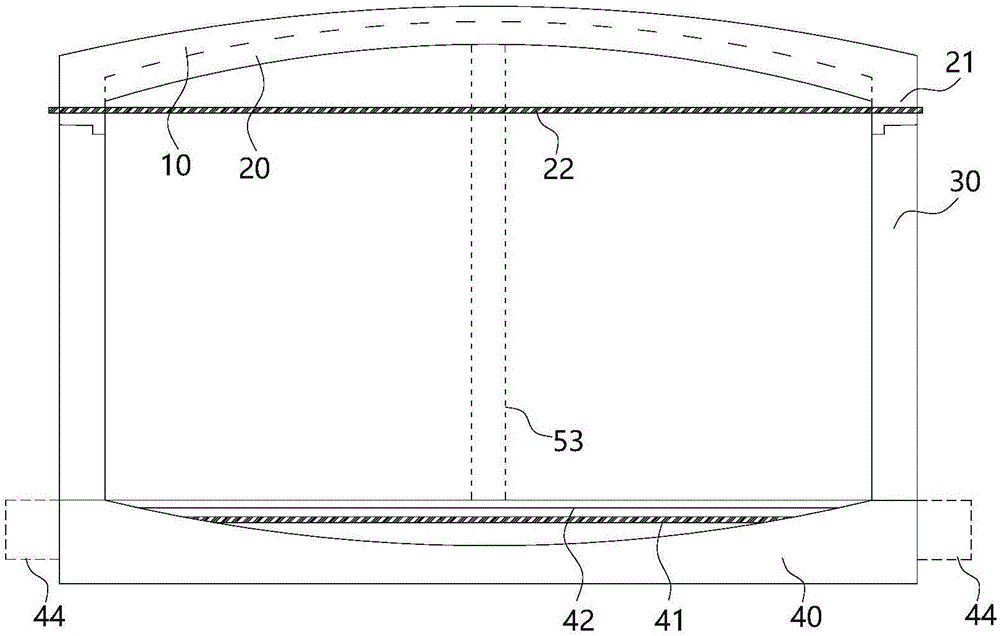

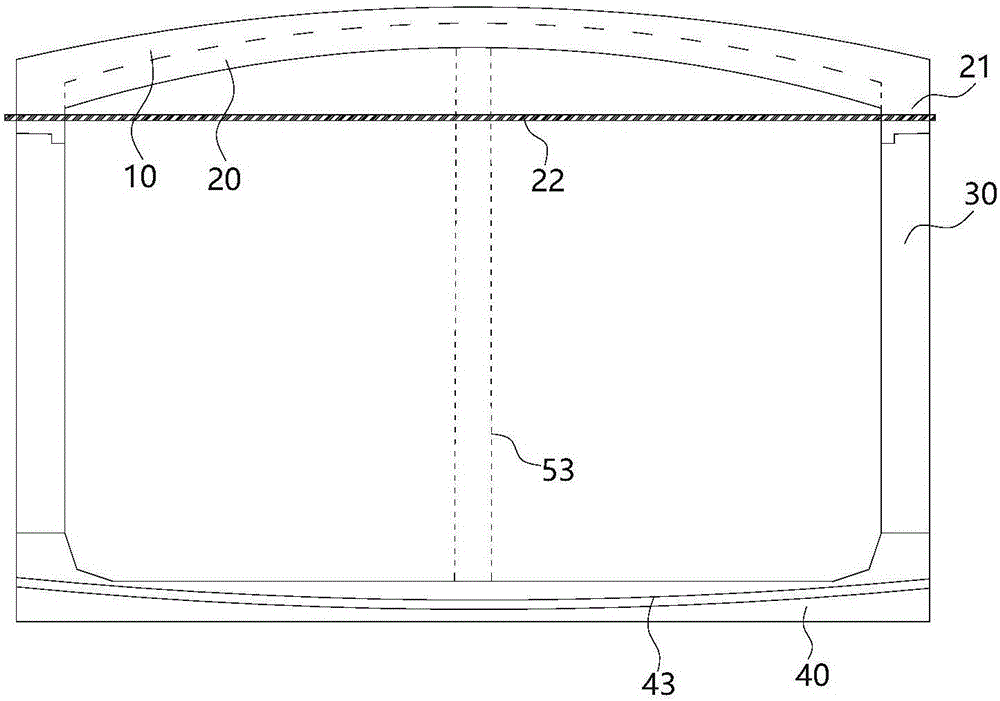

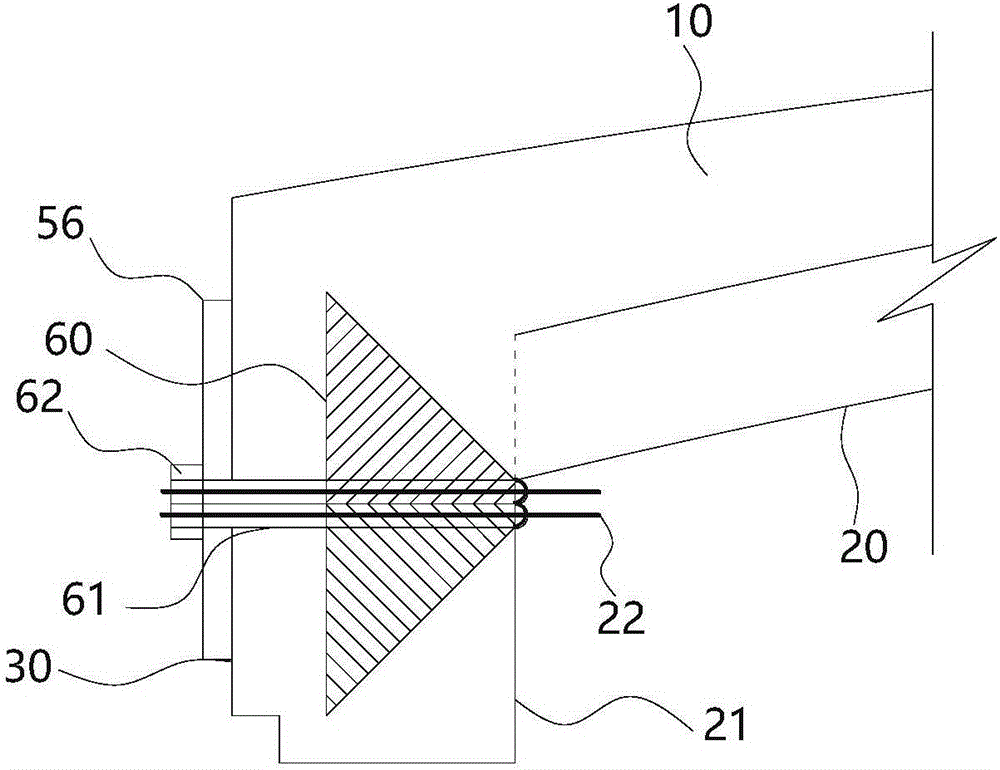

[0035] like figure 1 As shown, the large-span two-arch two-cable subway station structure of an open-cut method according to an embodiment of the present invention generally includes a side wall 30 arranged in the underground passage for supporting and preventing side wall earth and rocks from collapsing, and arranged at the end of the underground passage. The top is the top slab 10 that bears the load from above, the top beam 20 below the top slab 10 is supported by the side walls 30 on both sides, and the arch feet 21 arranged under the top beam 20 to connect with the side walls 30, and support the entire underground The bottom arch 40 of the channel, and the prestressed cables 22 that apply a horizontal tension to the top beam 20 .

[0036] Furthermore, in the channel formed by the top beam 20 and the bottom arch 40 , support columns 53 supporting the top beam 20 may also be arranged at intervals. The support columns 53 can overcome the settlement of the top plate 10 itsel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com