Low-temperature refrigerant liquid spraying device and automatic liquid spraying and supplementing method

A liquid spraying device and automatic liquid spraying technology, which is applied to machines that use refrigerant evaporation, refrigeration and liquefaction, refrigerators, etc., can solve the problems of reducing use efficiency, unable to maintain stable spray speed, and loss of low-temperature refrigerant. To achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

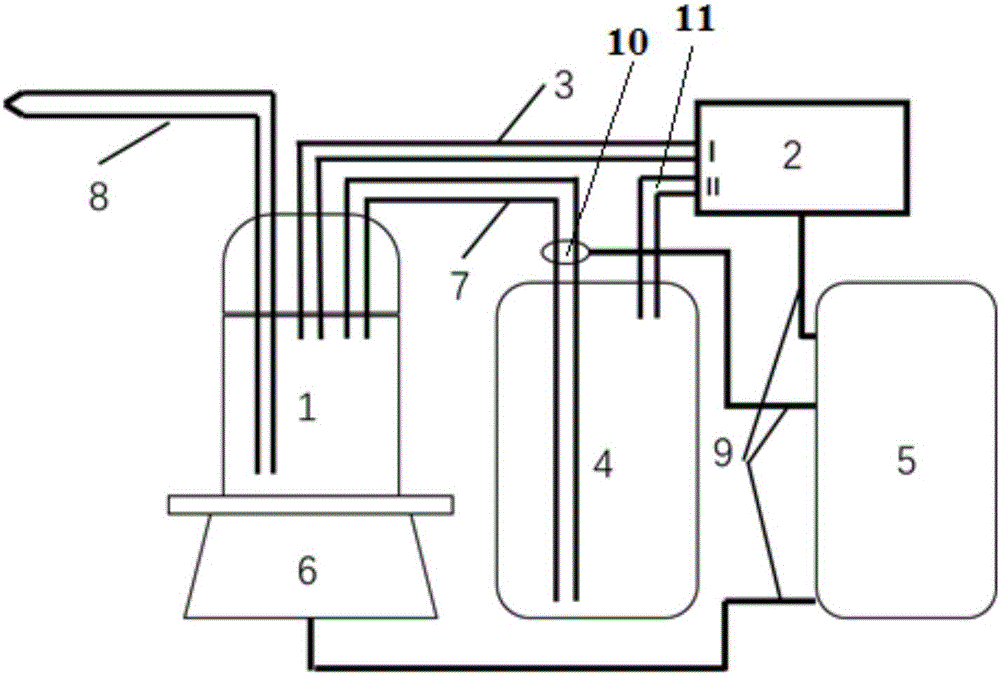

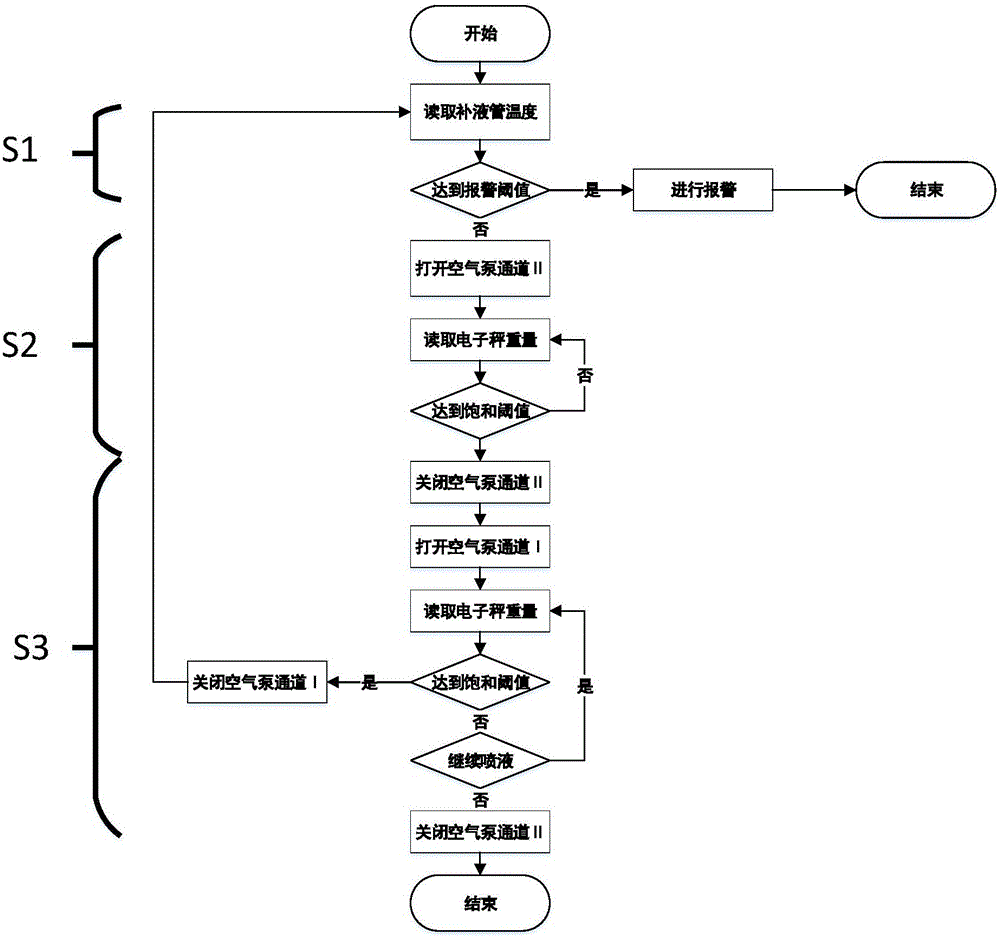

[0037] The structure of the low-temperature refrigerant spraying device in this embodiment is as follows: figure 1 As shown, the device includes a vacuum liquid spray container 1, a liquid spray booster pipe 3, a liquid spray pipe 8 and a dual-channel air pump 2. The empty liquid spray container 1 is filled with refrigerant. One end port of the liquid spray pipe 8 extends into the refrigerant in the vacuum liquid spray container 1 , and the other end port faces the target to be sprayed. Channel I (liquid injection channel) of the dual-channel air pump 2 is connected to one end of the liquid injection booster tube 3 , and the other end of the liquid injection booster tube 3 extends into the refrigerant in the vacuum liquid injection container 1 . The dual-channel air pump 2 provides pneumatic power to press the low-temperature refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com