Optical super-resolution dynamic imaging system and method based on microlens modified probe

A super-resolution, dynamic imaging technology, applied in the field of nanomanipulation, to achieve the effect of improving the efficiency and success rate, and expanding the capabilities of nanometer observation imaging and nanomanipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

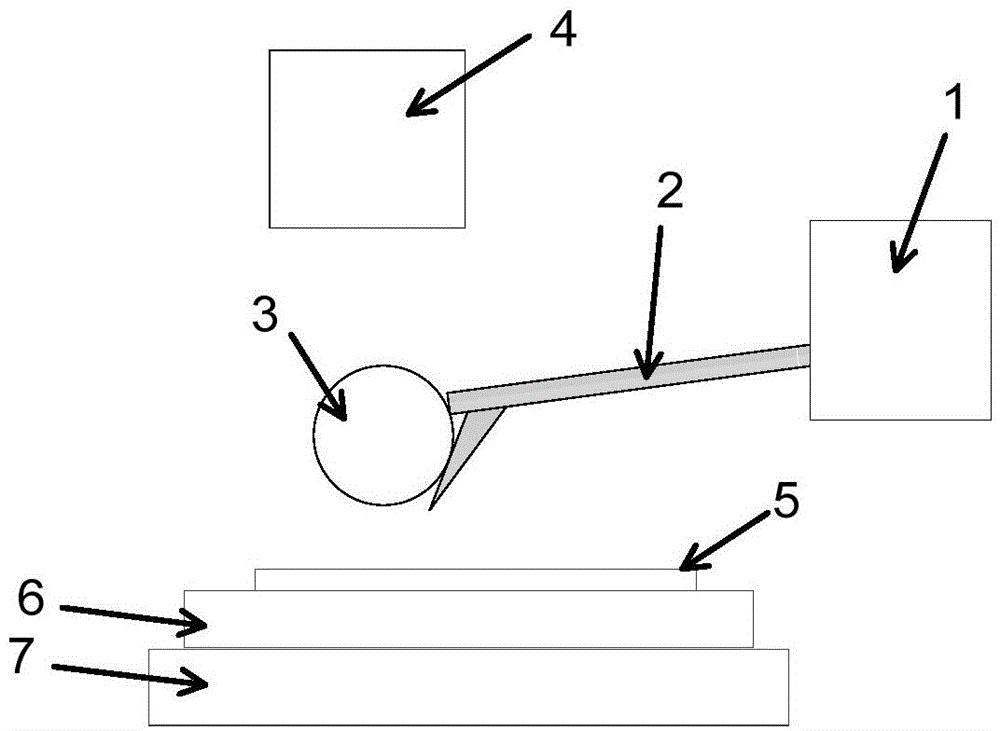

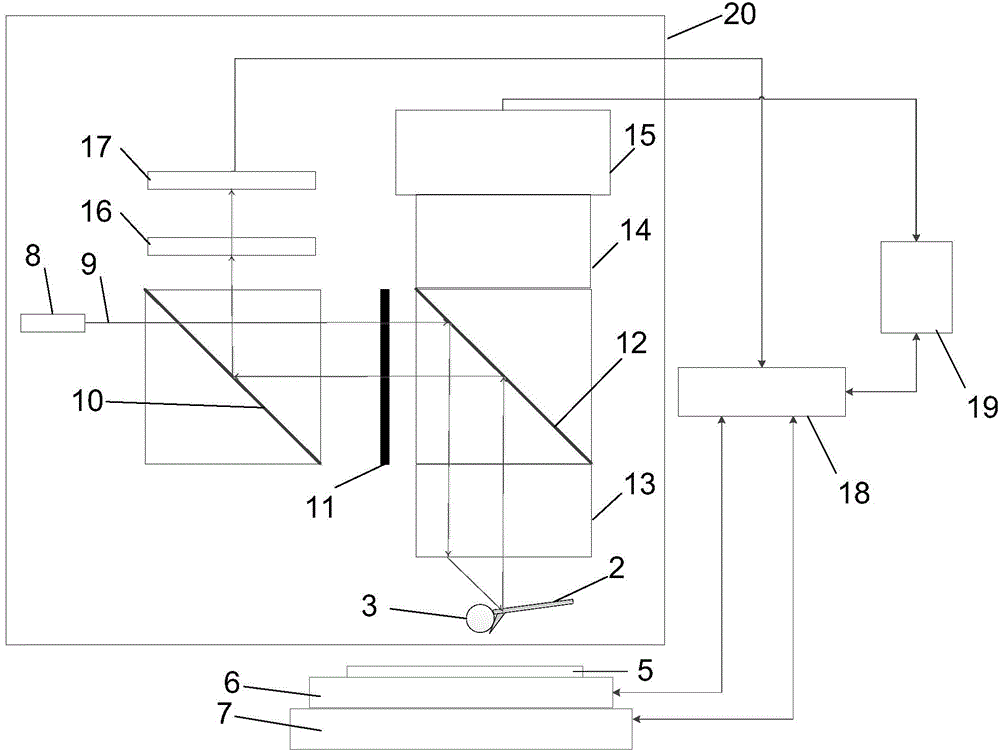

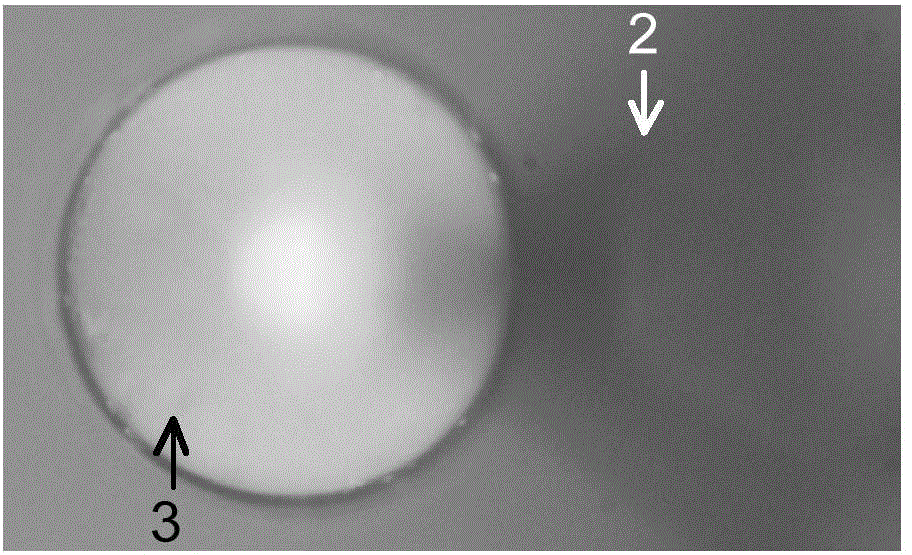

[0052] The implementation process of super-resolution optical imaging system constructed by combining microlens microscopy technology and atomic force microscopy technology is taken as an example.

[0053] Microlens Modification Probe Method:

[0054] 1) A capillary glass tube with a tapered tip, with a tip diameter of about 8 microns, is prepared by using a programmable laser puller (for example, P2000 / G, Sutter Instrument Company). The capillary glass tube is connected to the syringe through a hose and fixed on the micro-nano XYZ three-dimensional mobile platform.

[0055] 2) Use the fixed capillary to absorb a small amount of UV-curable adhesive NOA63, and control the tip of the capillary to move to the front end of the cantilever beam of the atomic force microscope probe fixed on the probe holder through the three-dimensional mobile platform, and release a small amount of NOA63 to the front end of the cantilever beam.

[0056] 3) Take an appropriate amount of barium titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com