Device for milling left bearing pedestal and right bearing pedestal

A bearing seat and milling processing technology is applied in the field of left and right bearing seat processing tooling, and left and right bearing seat milling and processing devices, which can solve problems such as troublesome calibration, affecting processing operations, affecting the accuracy of finished products, etc. Efficiency, the effect of eliminating manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

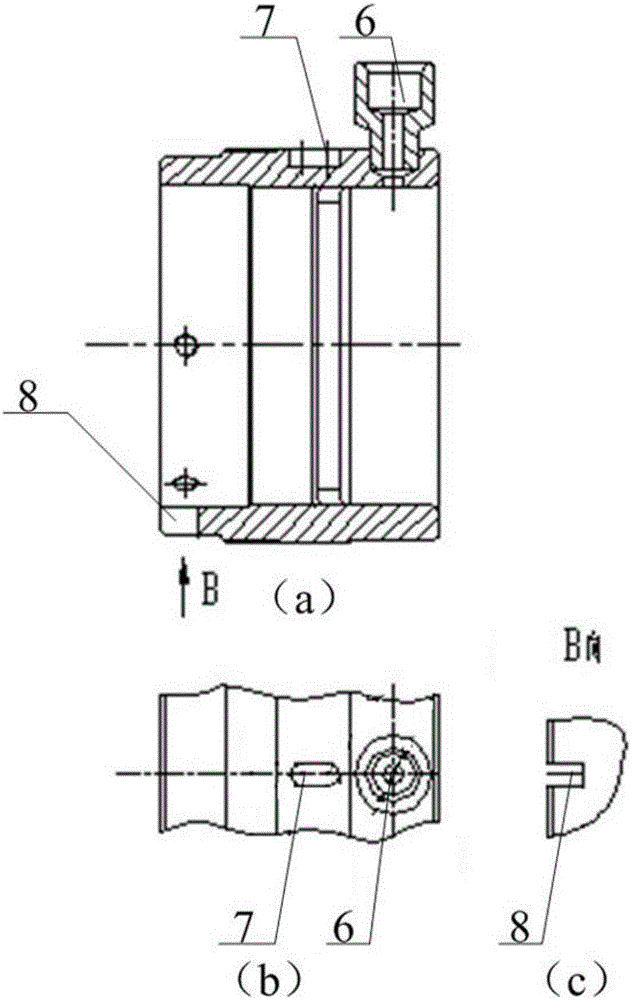

[0012] The invention is mainly used for milling of left and right bearing seats. Such as figure 1 As shown, the upper and lower symmetrical directions of the left and right bearing seats should be respectively provided with a keyway 7 and a notch 8, and a through hole 6 is provided next to the keyway 7, and the through hole 6 and the keyway 7 are located on the same center line; the centerline of the notch 8 and the keyway 7 Centerlines are parallel and lie in the same plane.

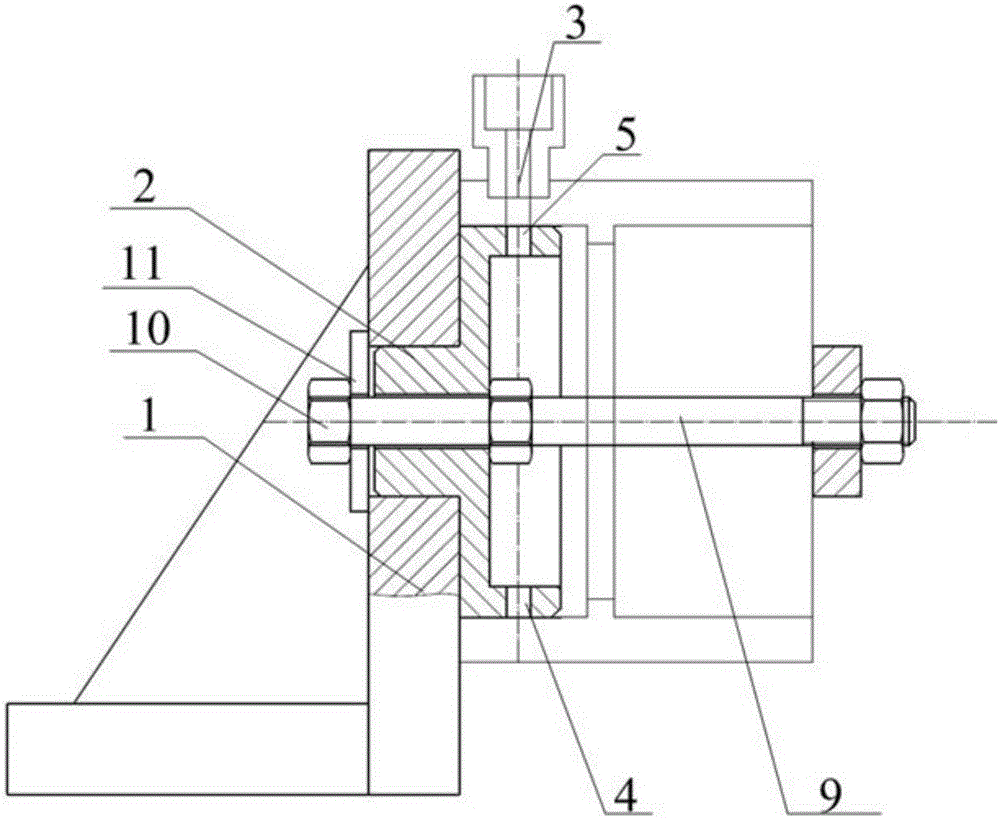

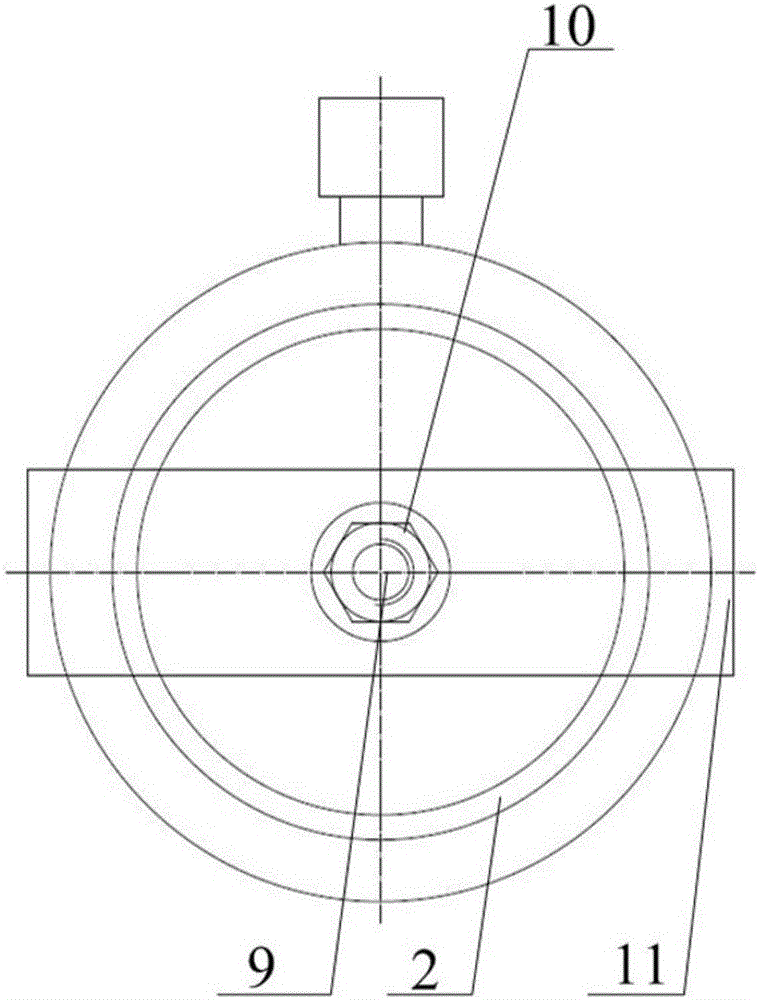

[0013] Such as figure 2 and 3 As shown, the device for milling the left and right bearing seats of the present invention includes a support 1, a positioning sleeve 2, a limit pin 3 and a pressing device. The support 1 has an L-shaped structure, and the positioning sleeve 2 has a ring structure, and the positioning sleeve 2 is installed on the elevation of the support 1 .

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com