Intelligent tool fault diagnosis method

A fault diagnosis and cutting tool technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems affecting production efficiency, consuming economic costs, and cutting tool fault diagnosis is not online and intelligent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the drawings and embodiments.

[0037] The present invention provides an intelligent tool fault diagnosis method, which includes the following steps:

[0038] 1) Set up a PLC between the CNC end of the machine tool (computer numerical control end) and the machine tool end, and the PLC realizes the input and output signal processing on the machine tool side and the CNC side.

[0039] 2) The PLC obtains several tool vibration signals x(t) generated during the machining process of the machine tool, and processes the collected tool vibration signals x(t) and extracts the tool characteristics:

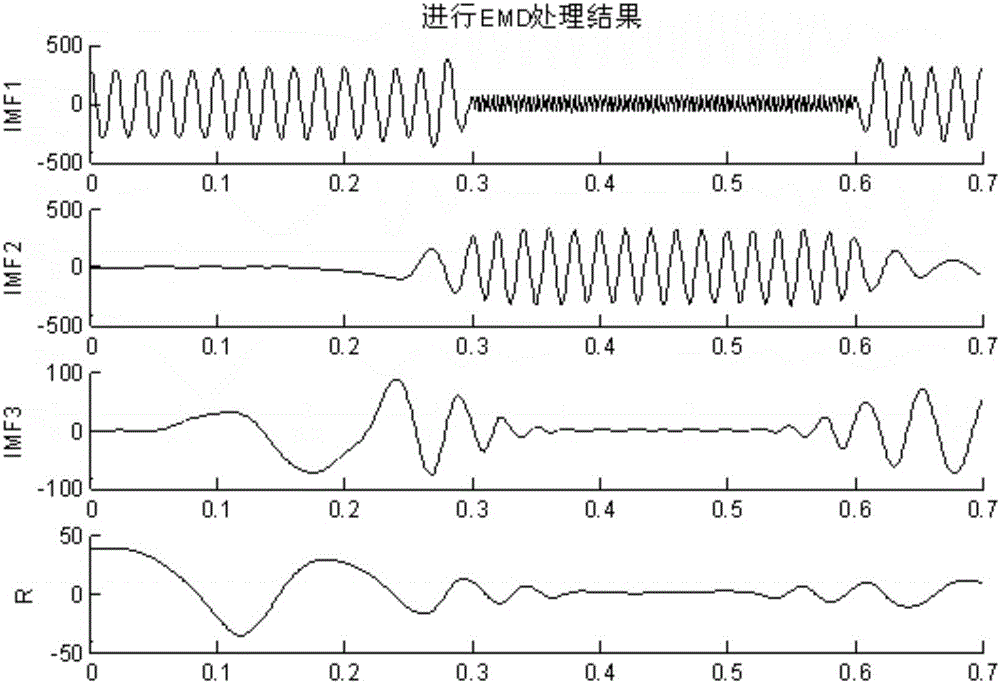

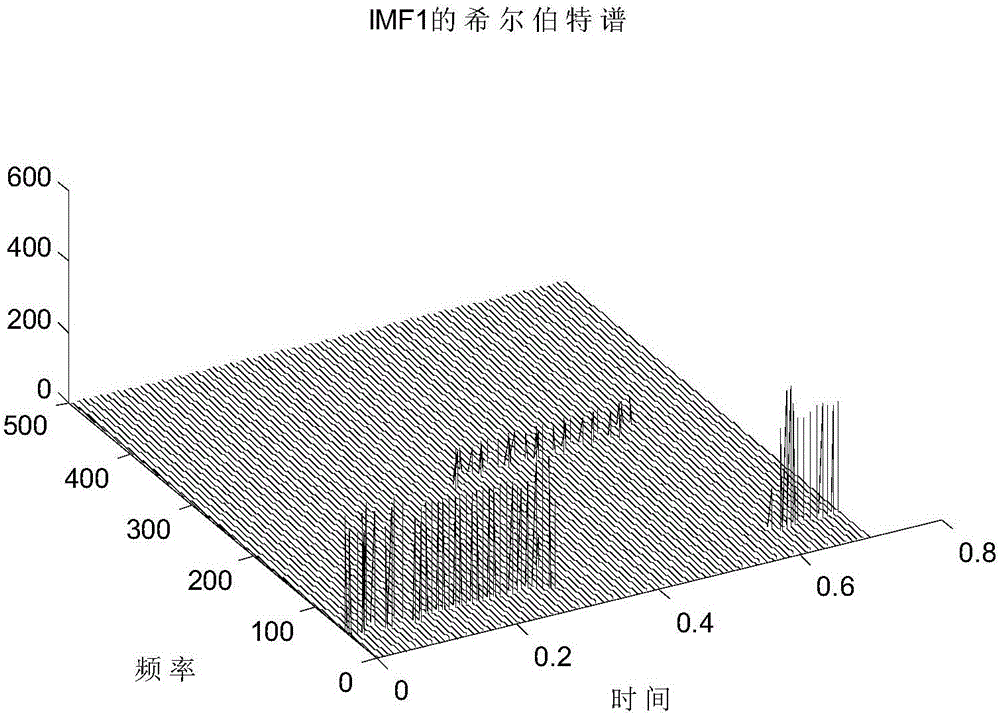

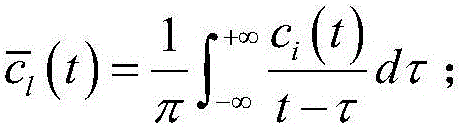

[0040] 2.1) Empirically decompose the collected tool vibration signal x(t), and decompose the fluctuations or trends of different scales in the tool vibration signal x(t) step by step to generate data sequences with different characteristic scales, and combine These sequences are defined as intrinsic mode functions (IM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com