Tire trimmer cutter loading device

A technology of trimming machine and knife device, which is applied in the field of automobile tire manufacturing, can solve the problems of high labor intensity, harsh working environment, and low production efficiency, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

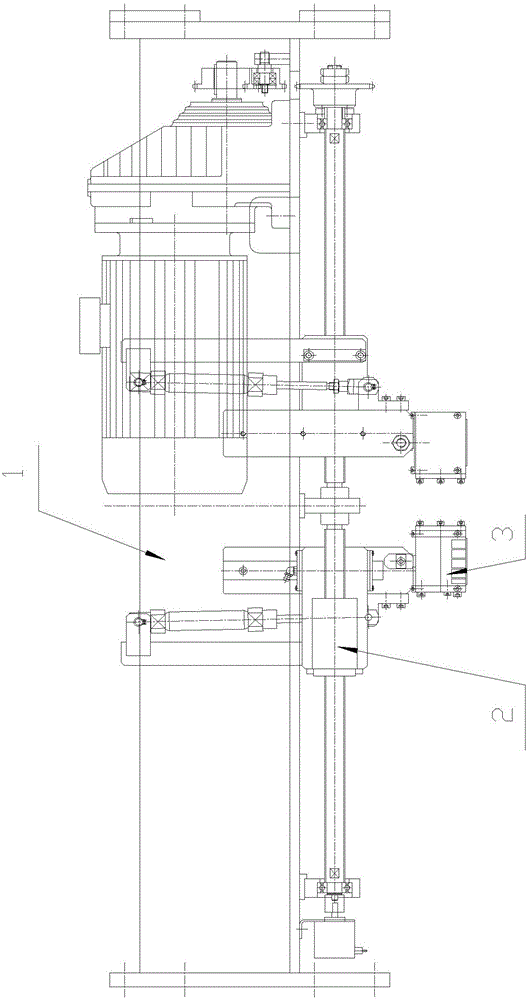

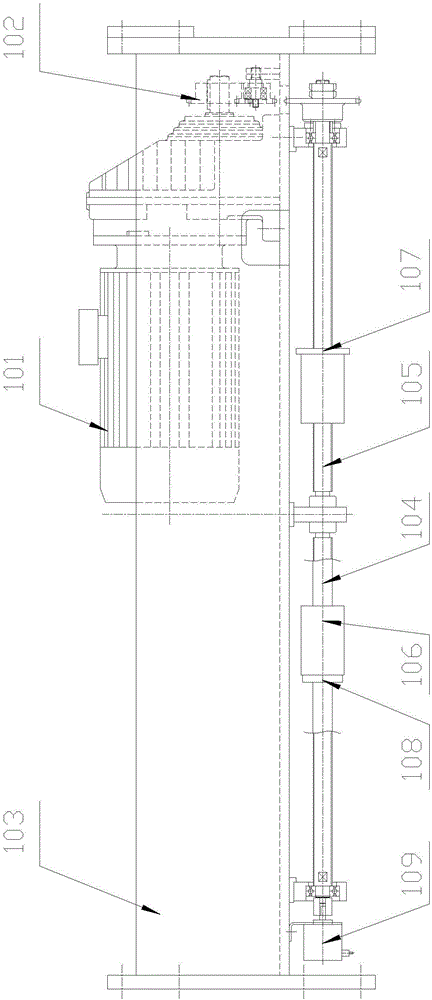

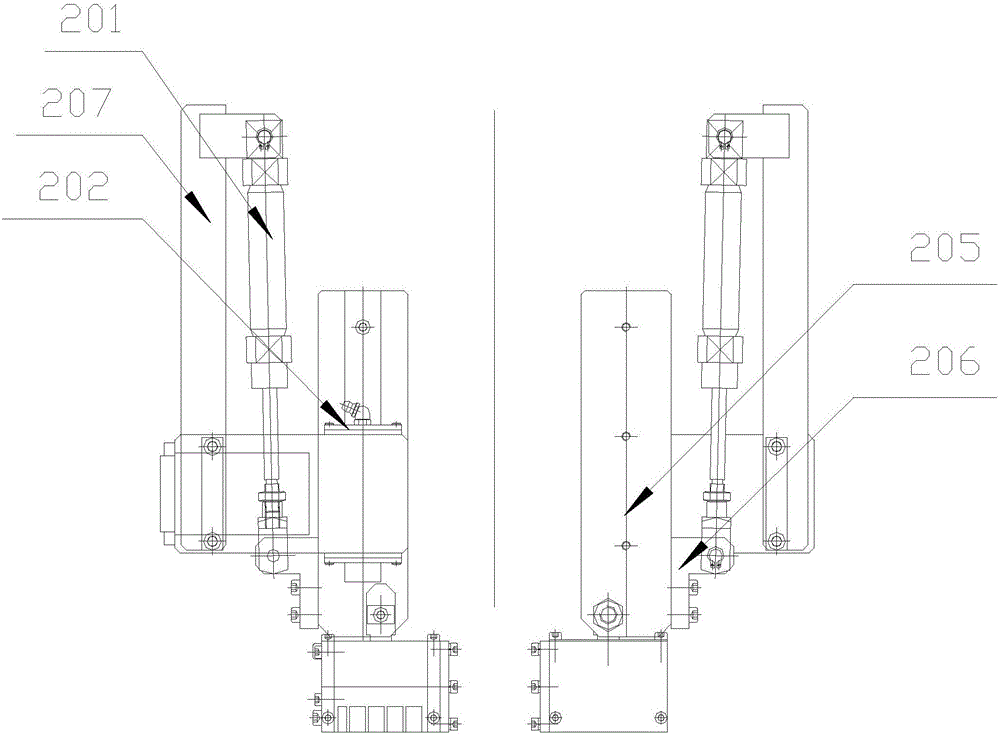

[0021] Such as Figure 1-5 As shown, a knife loading device for a tire edge trimmer of the present invention includes an opening and closing mechanism 1 and a knife loading mechanism 2 arranged on the opening and closing mechanism 1, and a knife seat 3 is provided on the said knife loading mechanism 2; Mechanism 1 comprises knife rest 103, and described knife rest 103 is provided with deceleration motor 101; The below of described knife rest 103 is equipped with ball screw 105 and guide post 104; 105 connection, one end of the ball screw 105 is connected to the encoder 109; it also includes a coupling block 106 installed on the ball screw 105 and the guide post 104; the upper knife mechanism 2 includes a cylinder 201, and one end of the cylinder 201 Connect the cylinder support plate 207, the other end of the cylinder 201 is connected to the cylinder connecting plate 206, the cylinder connecting plate 206 is connected to the linear guide rail mounting plate 205, and the linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com