Linkage laminated injection mold

An injection mold and lamination technology, applied in the field of linkage lamination injection mold, can solve the problems of low efficiency, high cost and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

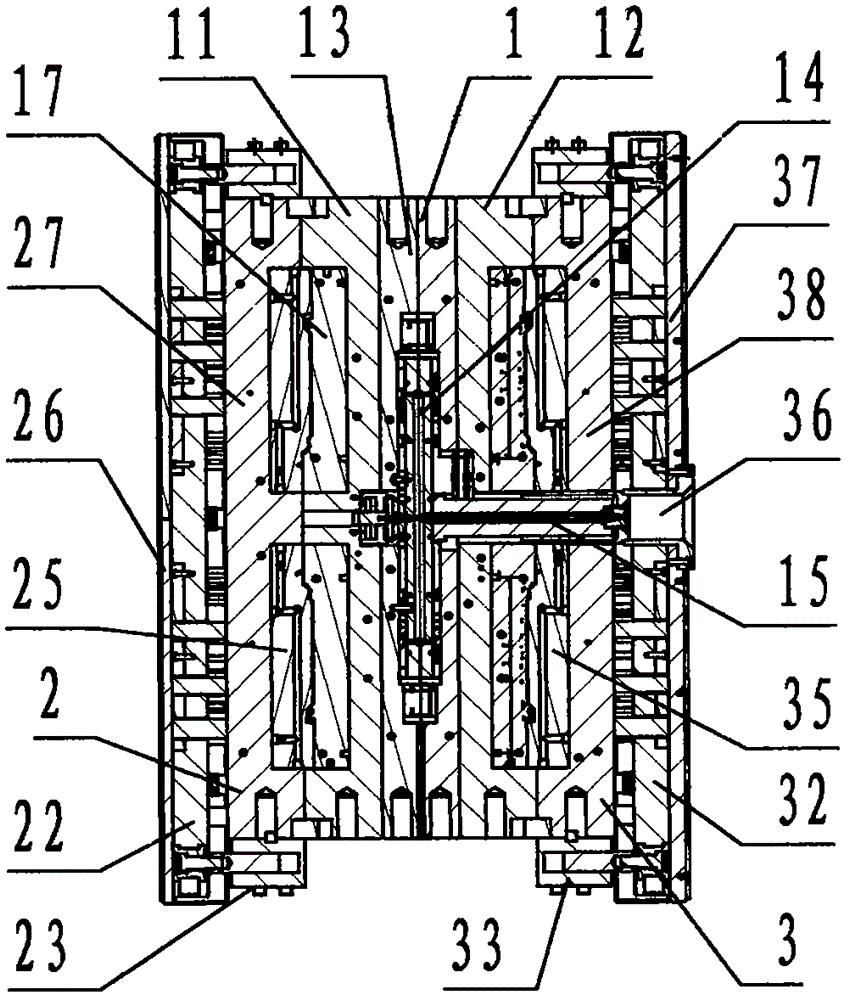

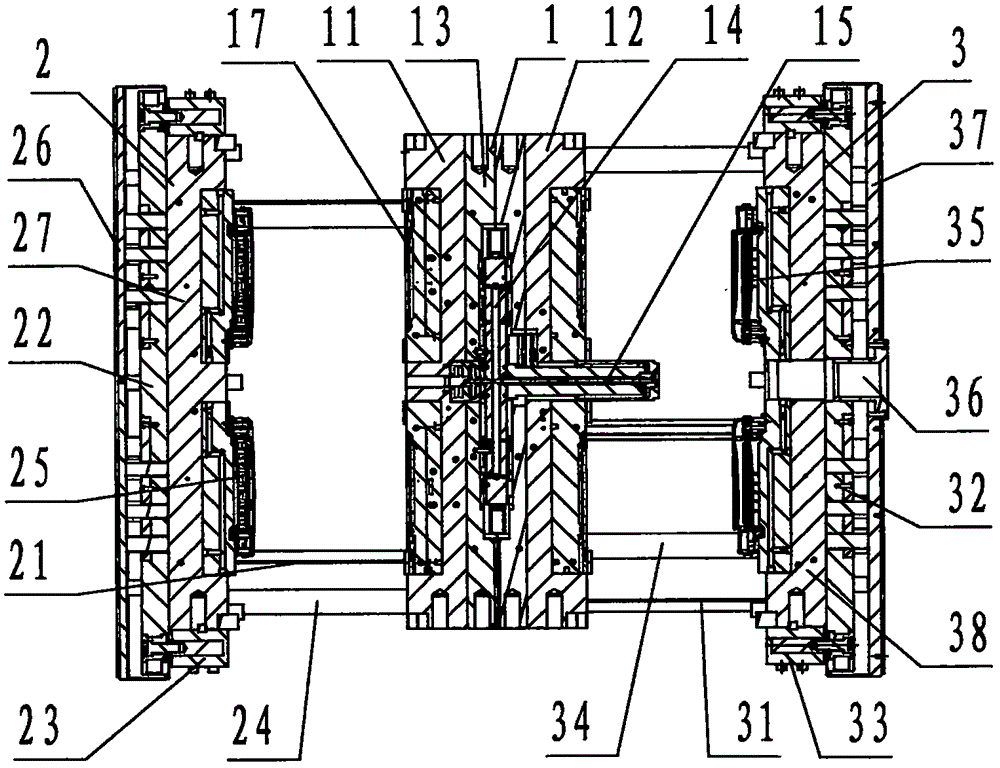

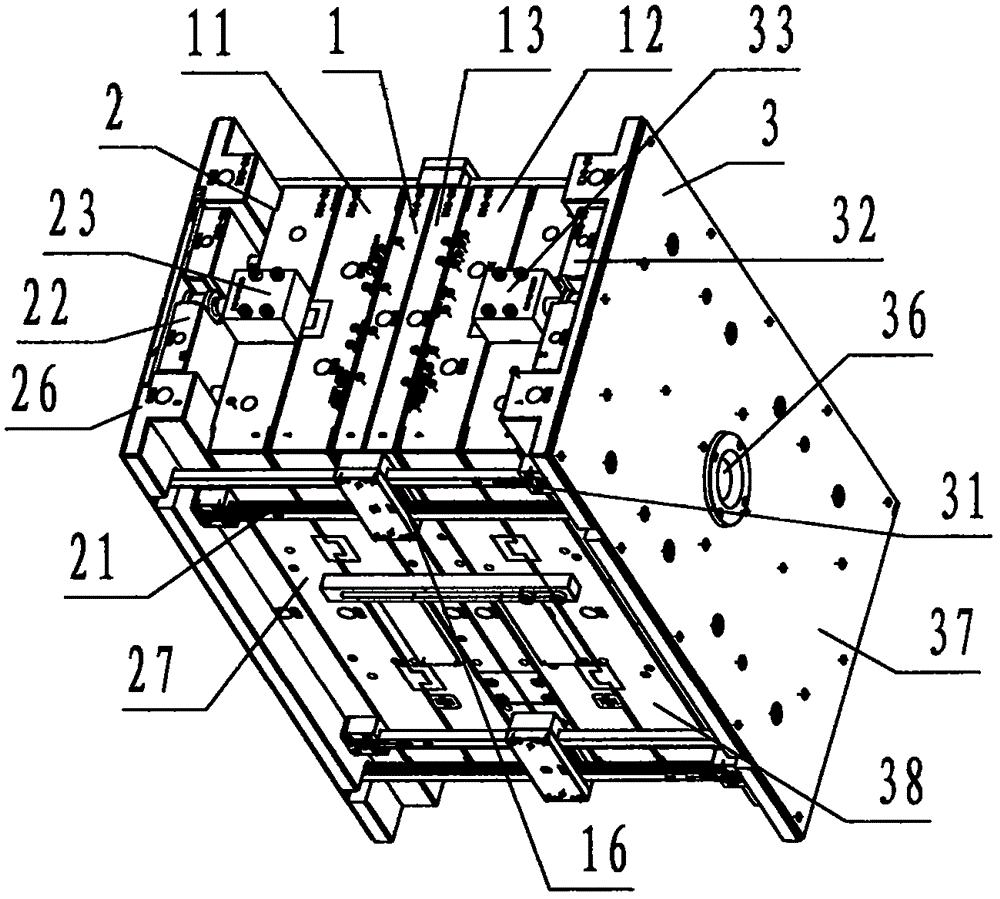

[0026] Refer to Figure 1 ~ Figure 4 , A linked laminated injection mold of the present invention includes a middle cavity template 1, a left core template 2, a right core template 3, wherein: the middle cavity template 1 is, in order from left to right, and is called A The cavity carrier board 11, the thermal fluid carrier board 13, and the B cavity carrier board 12 are fixedly connected and constituted by three rectangular plate-shaped steel members; wherein, the left side of the A cavity carrier board 11 is provided with two product cavities 17; The right side of the B cavity carrier plate 12 is provided with two product cavities 17; the center of the heat flux carrier plate 13 is provided with a cylindrical shape that passes through the B cavity carrier plate 12 and protrudes to the right Two cavities 17 connecting the sliding hot gate 15 and the A cavity carrier plate 11 and two cavities 17 of the B cavity carrier plate 12 are also provided inside the hot fluid carrier pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com