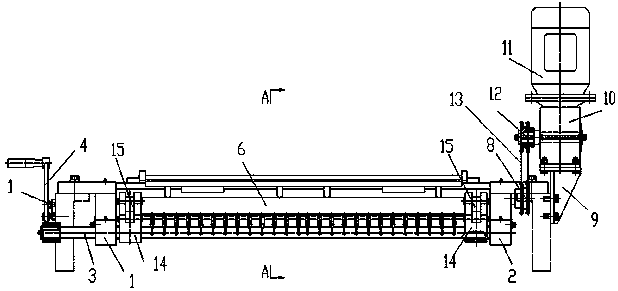

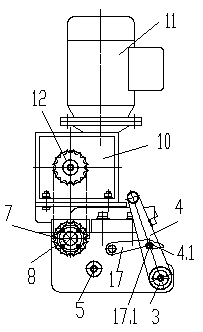

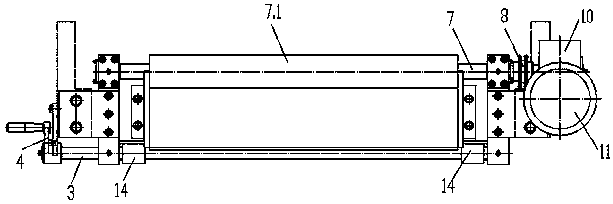

An ink fountain part of a nine-wheel two-color machine

A technology for ink fountains and parts, applied in the field of two-color machines, which can solve problems such as inability to adjust ink fountains, uneven ink printing and dyeing, and complex transmission systems, and achieve the effects of simple structure, easy operation, and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: An ink fountain part of a nine-wheel two-color machine, including symmetrically arranged left and right frames (1, 2), and the left and right frames (1, 2) are correspondingly provided with an ink fountain turning shaft hole, an ink fountain fixing shaft hole, and an ink roller Hole, the ink fountain turning shaft hole is located near the bottom of the left and right racks (1, 2), the ink fountain fixing shaft hole is located at the upper left of the ink fountain turning shaft hole, the ink roller hole is located at the upper left of the ink fountain fixing shaft hole, and the ink fountain is installed in the ink fountain turning shaft hole The turning shaft 3 is fixedly connected with the turning handle 4 at the left end of the turning shaft 3 of the ink fountain, and the fixing shaft 5 of the ink fountain is plugged into the hole of the fixing shaft of the ink fountain. The bottom plate 6.1 on the fixed shaft of the ink fountain, the ink fountain plate 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com