Throttle lever test frame

A technology of a throttle lever and a bracket, which is applied in the field of aircraft maintenance tooling, can solve the problems of affecting the work quality, increasing the production cost, difficult to see the correctness of the wire rope winding, etc., and achieving the effect of reducing the production cost and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

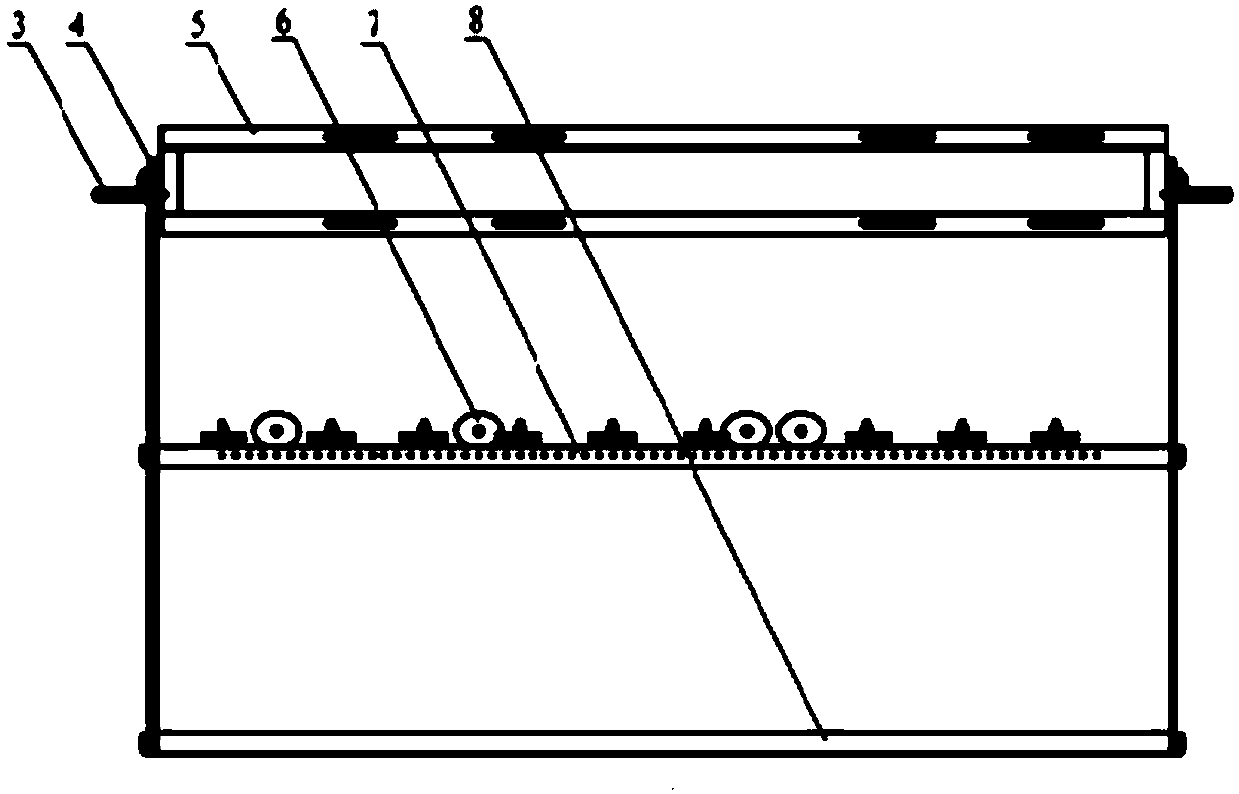

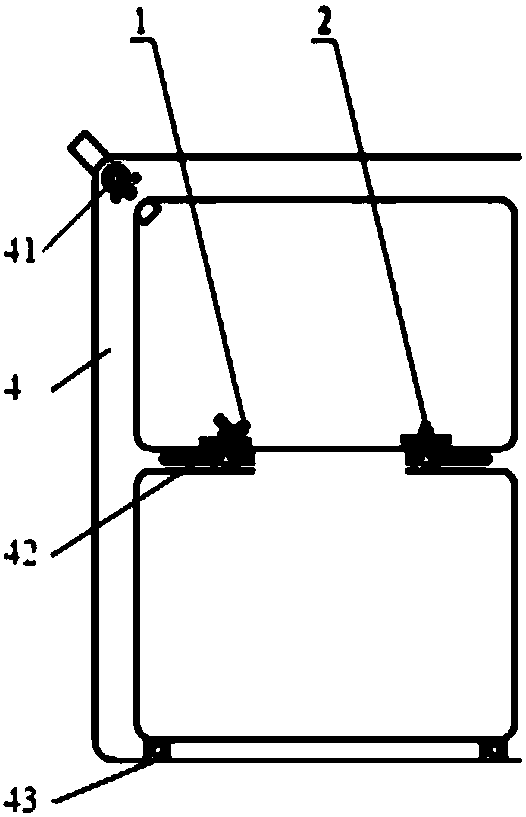

[0027] Referring to the accompanying drawings, a kind of throttle lever inspection frame includes: oblique support 1, straight support 2, stop pin 3, bracket 4, bracket 5, pulley 6, perforated stringer 7, non-perforated stringer 8 ;

[0028] The two brackets 4 are separated on both sides of the frame, the upper corner of the bracket 4 has a mounting hole 41 for the bracket 5, the middle part has a long hole 42 for installing the perforated stringer 7, and the lower part has a round hole for installing the non-porous stringer 8 43;

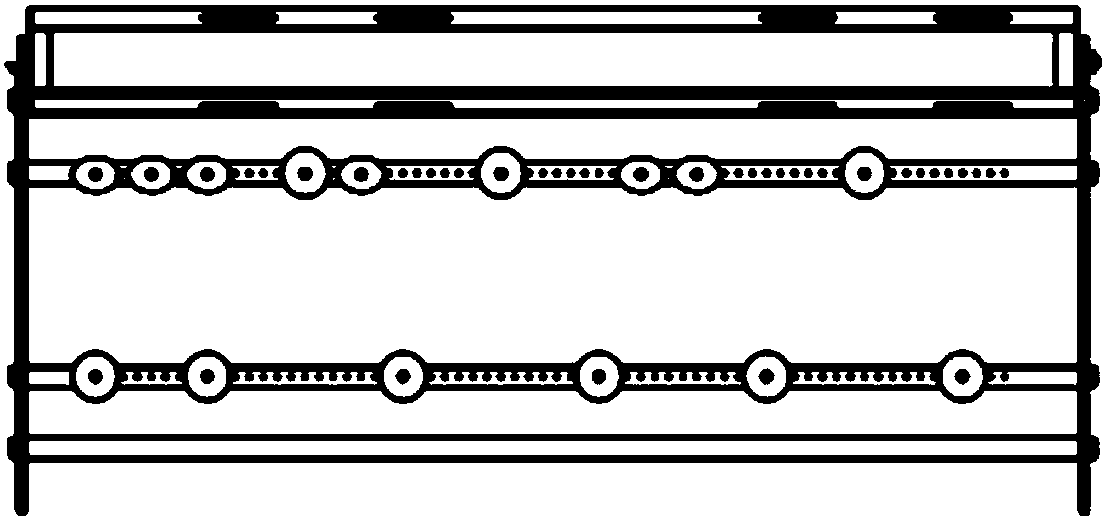

[0029] There are a plurality of long holes 51 for installing the throttle lever on the bracket 5, and shafts 52 for installation are welded at both ends; the shafts 52 at both ends of the bracket 5 are respectively hinged in the mounting holes 41 on the upper parts of the two brackets 4;

[0030] The perforated stringer 7 is divided into two parts, with mounting holes 71 at both ends and a mounting hole 72 for the pulley assembly 6 in the middle; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com