Self-separation method of cartoning machine

A self-separating and cartoning machine technology, used in packaging, conveyors, de-stacking of objects, etc., can solve the problems of inaccurate separation of trays and inaccurate insertion of fork plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A self-separating type unloading method of a cartoning machine comprises the following steps:

[0028] A. Place multiple stacked trays in the tray storage space 5;

[0029] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two set of fork plates 3 are the second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 are located under the lowermost tray, supporting multiple stacked trays;

[0030] C. The first set of fork plates 6 moves away from the tray and releases the tray, and the trays supported by two sets of fork plates 3 become a group of fork plates 3 supporting the tray;

[0031] D. After the first group of fork plates 6 move upward for a distance H, they are horizontally inserted between the bottom tray and the second-to-last tray to support th...

Embodiment 2

[0037] A self-separating type unloading method of a cartoning machine comprises the following steps:

[0038] A. Place multiple stacked trays in the tray storage space 5;

[0039] B. The front, rear, left and right four sides of the tray storage space 5 are each provided with at least one fork plate 3, and the two fork plates 3 provided in the front and rear directions are the first group of fork plates 6. The two set of fork plates 3 are the second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 are located under the lowermost tray, supporting multiple stacked trays;

[0040] C. The first set of fork plates 6 moves away from the tray and releases the tray, and the trays supported by two sets of fork plates 3 become a group of fork plates 3 supporting the tray;

[0041] D. After the first group of fork plates 6 move upward for a distance H, they are horizontally inserted between the bottom tray and the second-to-last tray to support th...

Embodiment 3

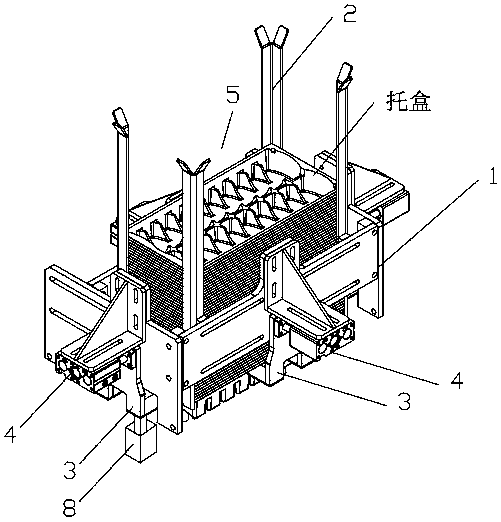

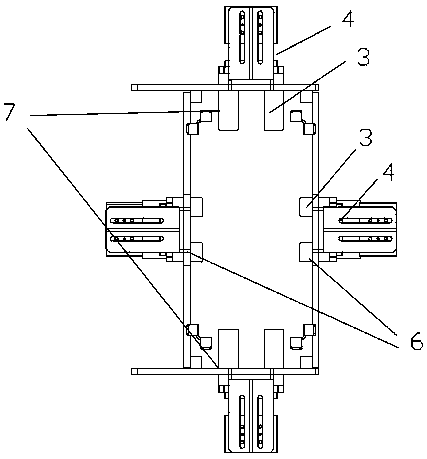

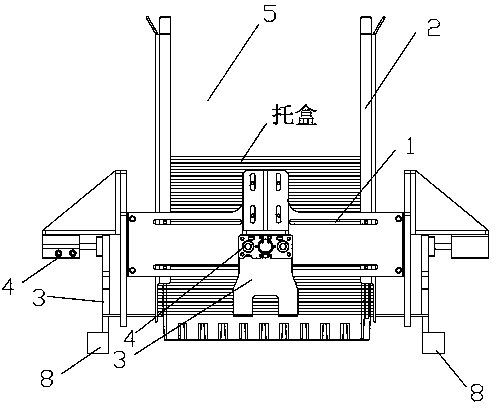

[0049] The equipment that realizes embodiment 1 and embodiment 2 can be the unboxing mechanism of product cartoning machine, and it comprises fixed frame 1, and a plurality of guard plates 2 that fix the position of tray box are installed in described fixed frame 1, and the adjacent Fork plates 3 are arranged between the guard plates 2, and the guard plates 2 surround and form a tray storage space 5 for placing trays. The front, rear, left and right directions of the tray storage space 5 are each provided with at least One fork plate 3, the two fork plates 3 arranged in front and rear directions are the first group of fork plates 6, and the two fork plates 3 arranged in the left and right directions are the second group of fork plates 7, the first group of fork plates The fork plates 6 and the second set of fork plates 7 alternately perform horizontal reciprocating motions in the horizontal direction, and the first set of fork plates 6 and the second set of fork plates 7 altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com