A carton unloading mechanism of a cartoning machine

A cartoning machine and unloading technology, used in packaging, conveyors, destacking of objects, etc., can solve problems such as the inaccurate insertion of the fork plate and the inaccurate separation of the trays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

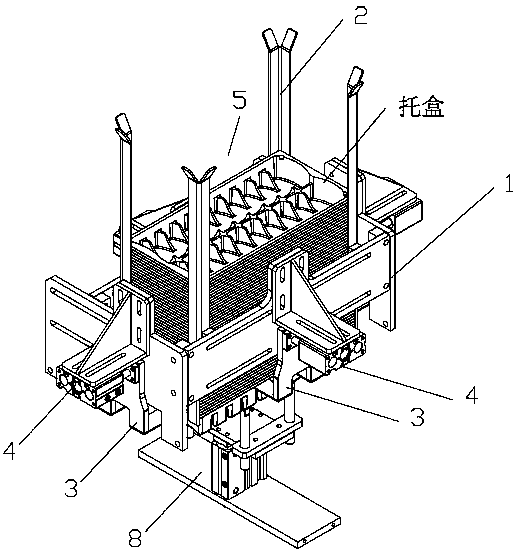

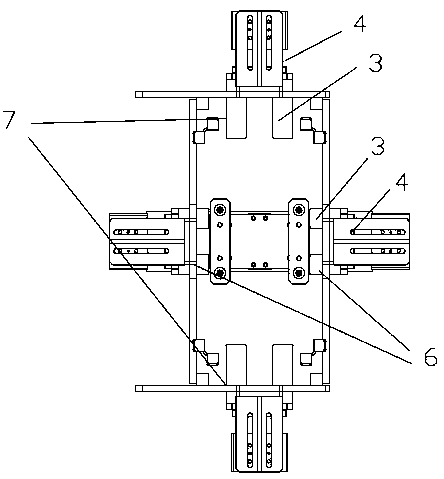

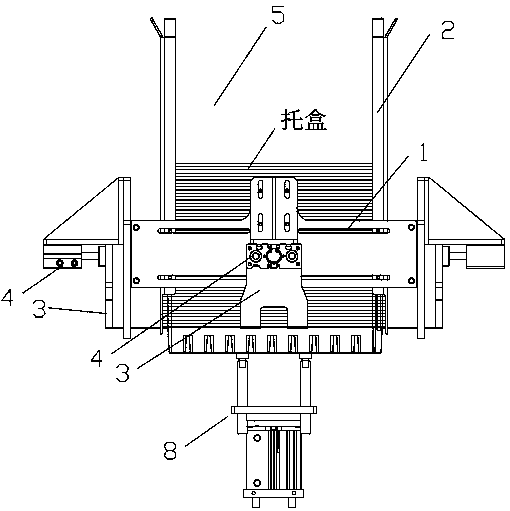

[0028] A box-down mechanism of a cartoning machine comprises a fixed frame 1, a plurality of guard plates 2 for fixing the position of the tray box are installed in the fixed frame 1, fork plates 3 are arranged between the adjacent guard plates 2, and the The fork plate 3 is connected with the fork plate cylinder 4, and a negative pressure device 8 is arranged below the guard plate 2, and the guard plate 2 surrounds and forms a tray storage space 5 for placing trays. At least one fork plate 3 is respectively arranged in the four directions of rear, left and right, and the two fork plates 3 arranged in the front and rear directions are the first set of fork plates 6, and the two fork plates 3 arranged in the left and right directions are The second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 alternately perform horizontal reciprocating motions in the horizontal direction.

[0029] The working principle of the lower box mechanism is: ...

Embodiment 2

[0033] A box-down mechanism of a cartoning machine comprises a fixed frame 1, a plurality of guard plates 2 for fixing the position of the tray box are installed in the fixed frame 1, fork plates 3 are arranged between the adjacent guard plates 2, and the The fork plate 3 is connected to the fork plate cylinder 4, and a negative pressure device 8 is arranged below the guard plate 2, and the guard plate 2 surrounds and forms a tray storage space 5 for placing trays. At least one fork plate 3 is respectively arranged in the four directions of rear, left and right, and the two fork plates 3 arranged in the front and rear directions are the first set of fork plates 6, and the two fork plates 3 arranged in the left and right directions are The second set of fork plates 7, the first set of fork plates 6 and the second set of fork plates 7 alternately perform horizontal reciprocating motions in the horizontal direction.

[0034] The first set of fork plates 6 and the second set of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com