Adjustable cartoning frame for the lower carton mechanism

An adjustable, boxing technology, applied in packaging, object destacking, transportation and packaging, etc., can solve problems such as the inability to use a universal transmission mechanism, the inability to accurately separate the trays, and the inability to accurately insert the fork plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

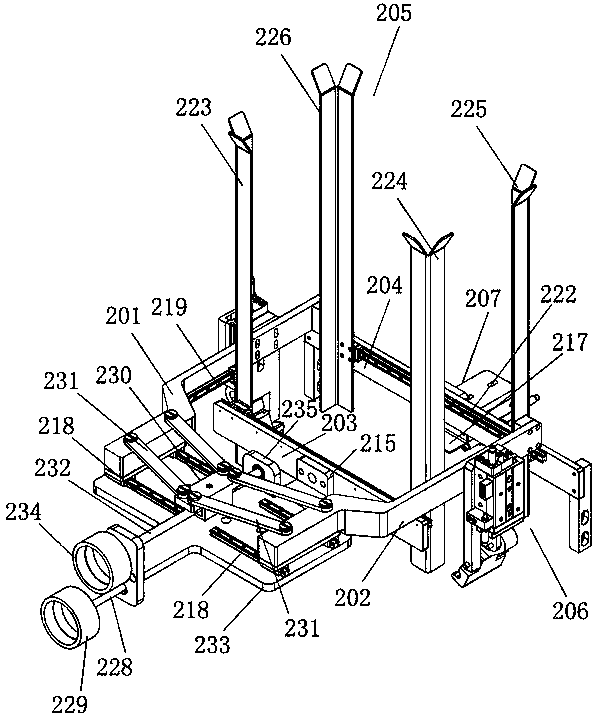

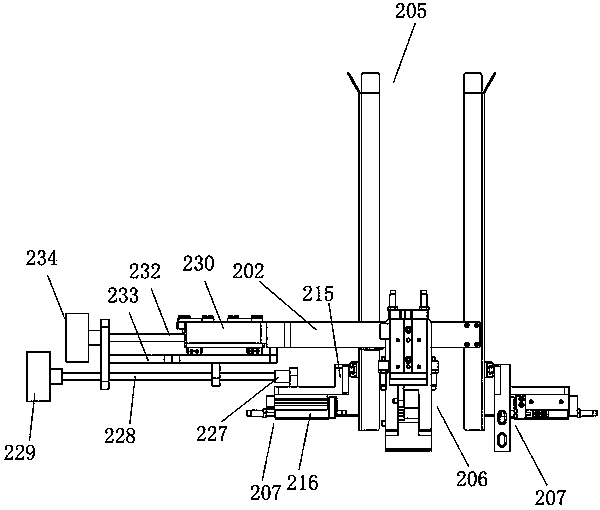

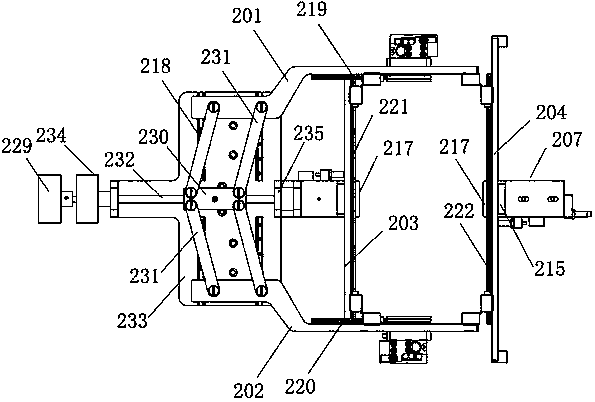

[0044] The adjustable box-loading frame of lower box mechanism comprises the installation left plate 201 and the installation right plate 202 of adjustable left and right spacing, the installation front plate 203 of adjustable front and rear spacing and the installation rear plate 204, described installation left plate 201, installation right plate 202. Both the front panel 203 and the rear panel 204 are vertically provided with a guard plate 205 for limiting the position of the tray, and the guard plate 205 surrounds and forms a tray storage space for placing the tray. The spacing between the left panel 201 of the adjustable box frame 200 and the installation of the right panel 202 can be realized by changing the horizontal position of the two, and the spacing between the front panel 203 and the rear panel 204 can be achieved by changing the level of the two. The position is realized, and the tray storage space formed by guard plates 205 is used for storing trays. When these ...

Embodiment 2

[0046] The adjustable box-loading frame of lower box mechanism comprises the installation left plate 201 and the installation right plate 202 of adjustable left and right spacing, the installation front plate 203 of adjustable front and rear spacing and the installation rear plate 204, described installation left plate 201, installation right plate 202. Both the front panel 203 and the rear panel 204 are vertically provided with a guard plate 205 for limiting the position of the tray, and the guard plate 205 surrounds and forms a tray storage space for placing the tray.

[0047] There are two situations for setting the fork plate 217:

[0048] The first case: the installation left plate 201 and the installation right plate 202 are equipped with a rotating fork plate 206 that rotates around the connection point 212, and the installation front plate 203 and the installation rear plate 204 are equipped with a horizontal fork plate 207 for horizontal movement .

[0049] The secon...

Embodiment 3

[0056] The adjustable box-loading frame of lower box mechanism comprises the installation left plate 201 and the installation right plate 202 of adjustable left and right spacing, the installation front plate 203 of adjustable front and rear spacing and the installation rear plate 204, described installation left plate 201, installation right plate 202. Both the front panel 203 and the rear panel 204 are vertically provided with a guard plate 205 for limiting the position of the tray, and the guard plate 205 surrounds and forms a tray storage space for placing the tray.

[0057] There are two situations for setting the fork plate 217:

[0058] The first case: the installation left plate 201 and the installation right plate 202 are equipped with a rotating fork plate 206 that rotates around the connection point 212, and the installation front plate 203 and the installation rear plate 204 are equipped with a horizontal fork plate 207 for horizontal movement .

[0059] The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com