Fixing fixture for tin fillet scroll

A technology for fixing jigs and reels, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., and can solve problems such as cable disorder, waste of resources, and defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

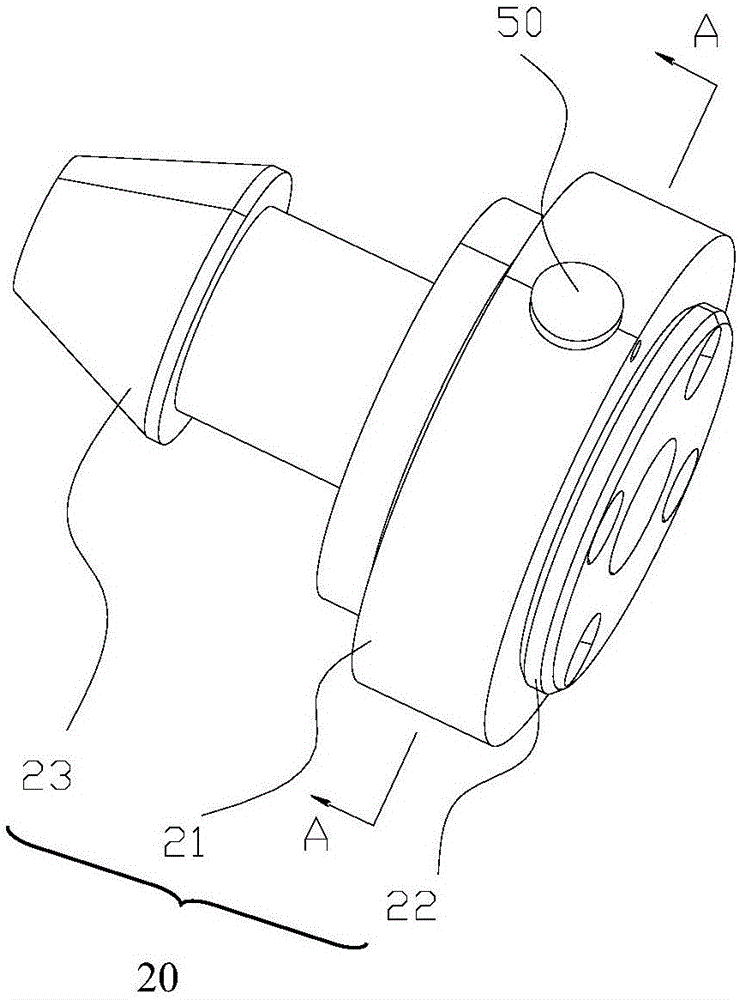

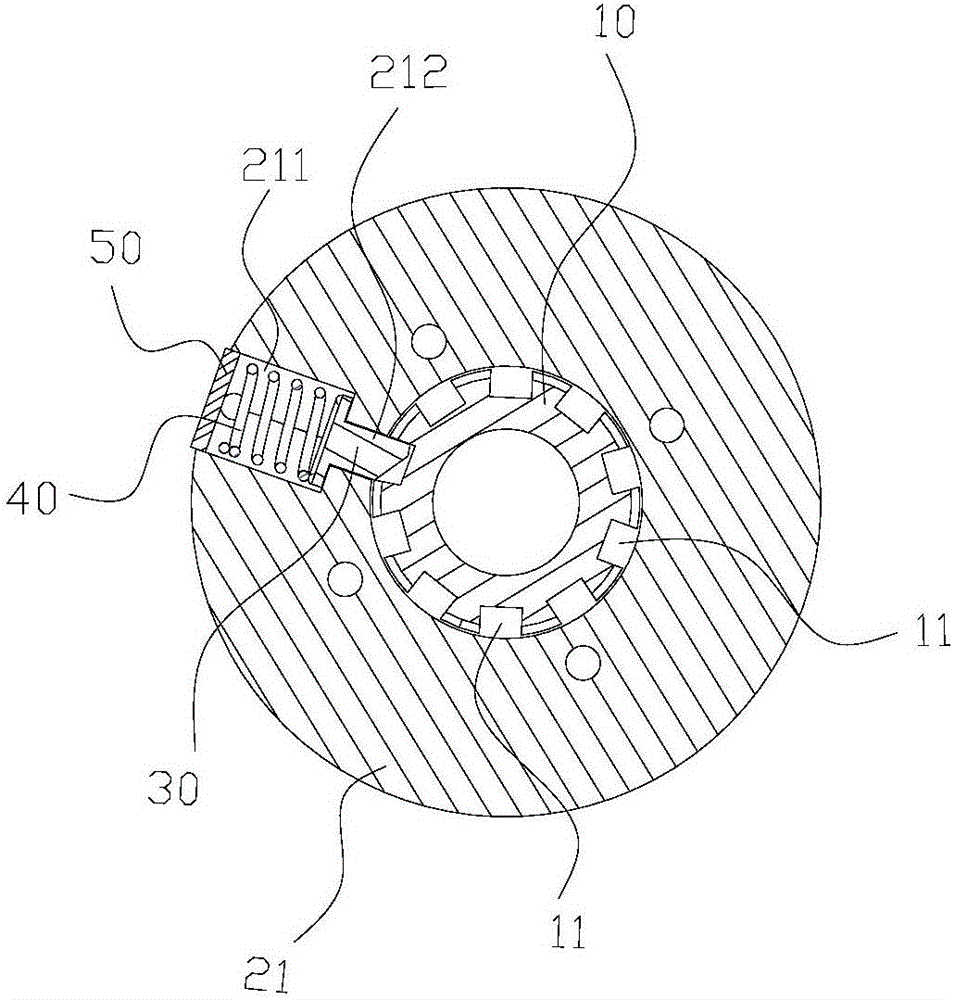

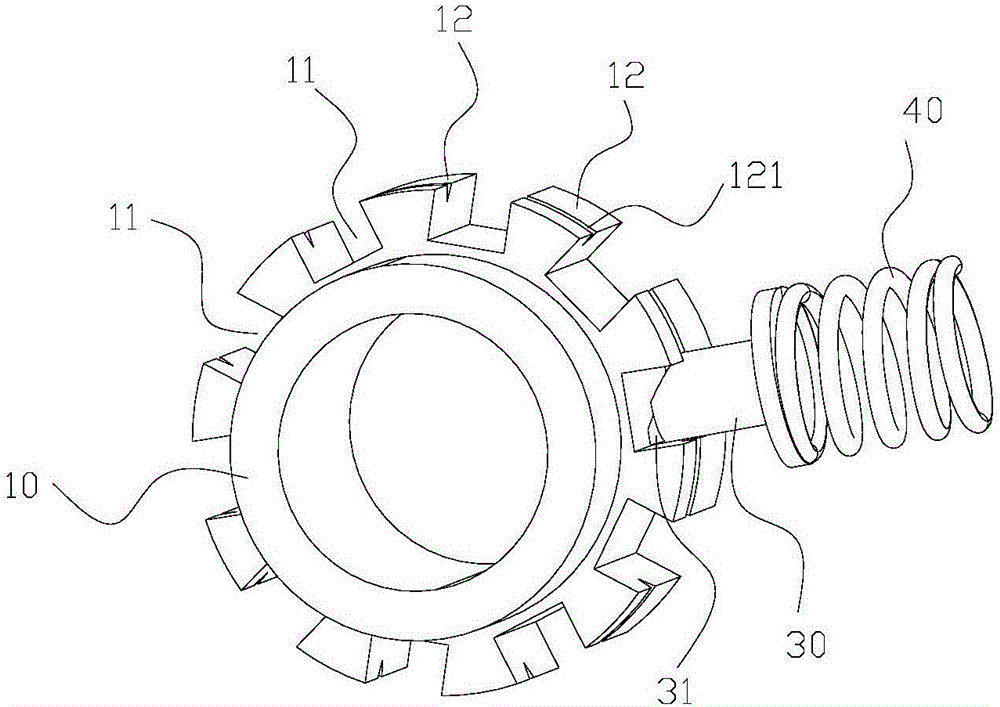

[0009] Combine below Figure 1-Figure 3 , to further describe the present invention.

[0010] A fixing fixture for a tin ribbon reel, comprising a torsion nut 10, the torsion nut 10 is arranged in the chamber of the torsion ring 20, the internal thread of the torsion nut 10 is compatible with the external thread on the shaft of the winding motor, and the torsion ring 20 Arrange the through opening for the shaft body of the wire-receiving motor shaft to pass through. The outer circumference of the torque nut 10 is arranged with grooves 11 at intervals in the circumferential direction, and a convex part 12 is formed between two adjacent grooves 11. The torque ring 20 and the torque nut 10 are connected by a top card 30 and a spring 40, one end of the top card 30 is clamped in the groove 11 and the end face of the end is a slope, the other end of the top card 30 is connected with the spring 40, and the spring 40 is arranged on the torsion ring 20 Inside, the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com