Fuel supply apparatus

A fuel supply device and fuel technology, applied in the direction of liquid fuel feeder, charging system, machine/engine, etc., can solve the problems of increased mold cost and complexity of forming filter devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described based on the drawings.

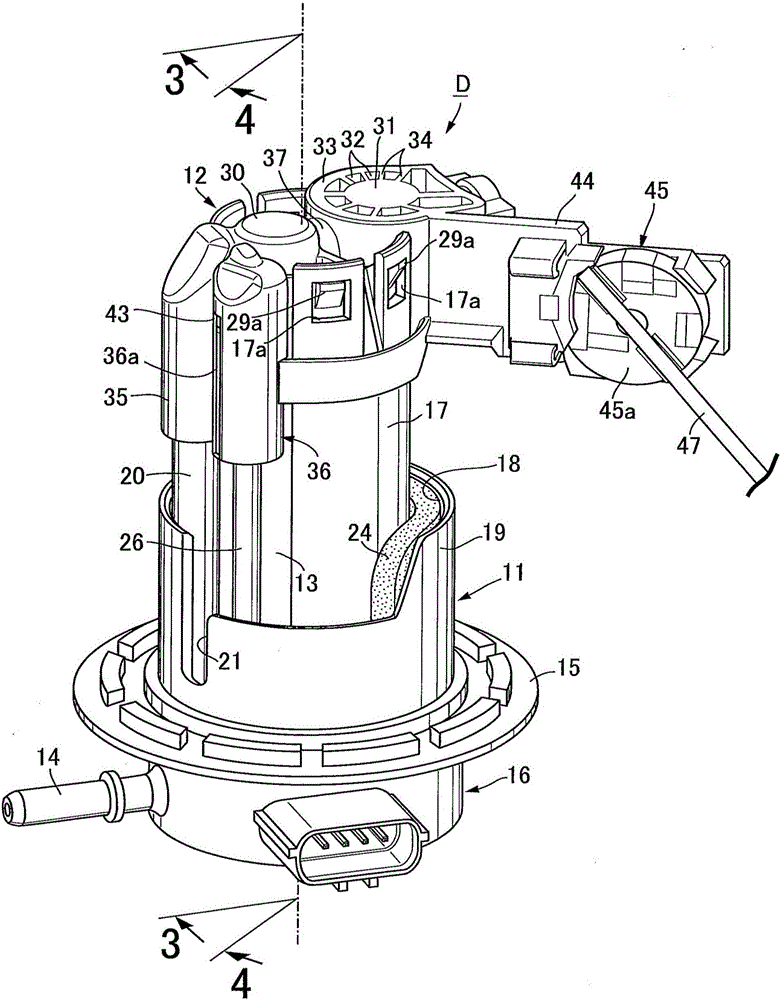

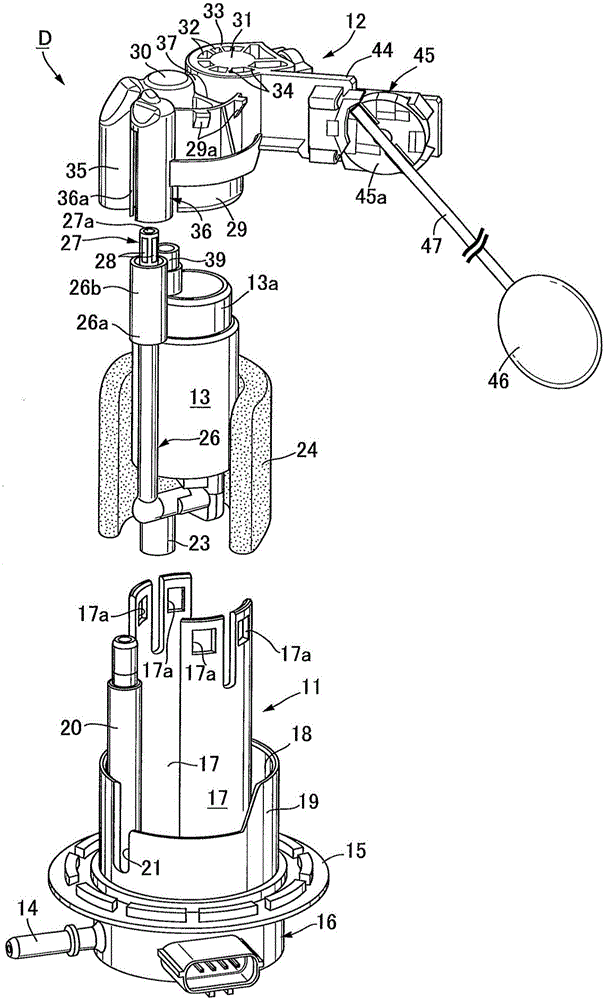

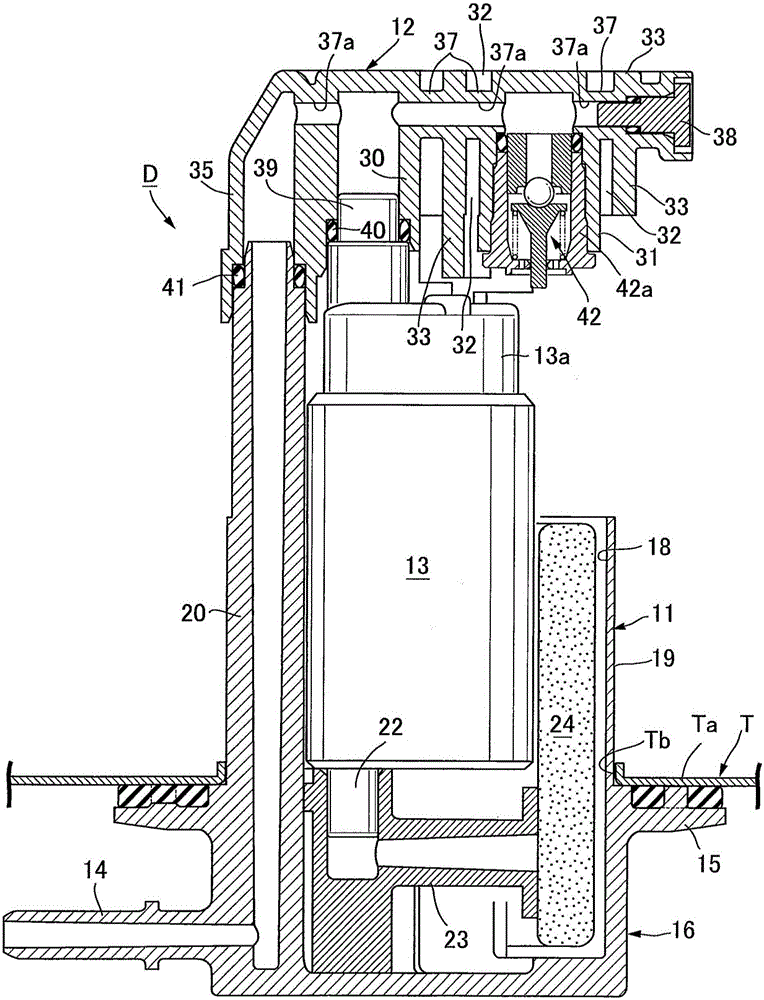

[0029] First of all, in Figure 1 ~ Figure 4 In the bottom plate Ta of the fuel tank T mounted on the vehicle (refer to image 3 with Figure 4 ), the fuel supply device D of the present embodiment that supplies the fuel in the fuel tank T to the fuel injection valve (not shown) of the engine is installed.

[0030] The fuel supply device D includes: a first housing 11 made of synthetic resin attached to the bottom plate Ta of the fuel tank T; a second housing made of synthetic resin connected to the first housing 11 and arranged in the fuel tank T Body 12; and a fuel pump 13 held between the first housing 11 and the second housing 12.

[0031] The first housing 11 is integrally formed with a bottomed cylindrical base portion 16 with a fuel take-out pipe 14 at the lower part and a mounting flange 15 mounted around the opening Tb of the bottom plate Ta of the fuel tank T at the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com