High-precision nozzle clogging detection and processing system and detection and processing method

A technology for blockage detection and processing system, which is applied in the fields of processing data acquisition/processing, manufacturing auxiliary devices, additive processing, etc., and can solve problems such as inability to adapt to 3D printers, signal delays or errors, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

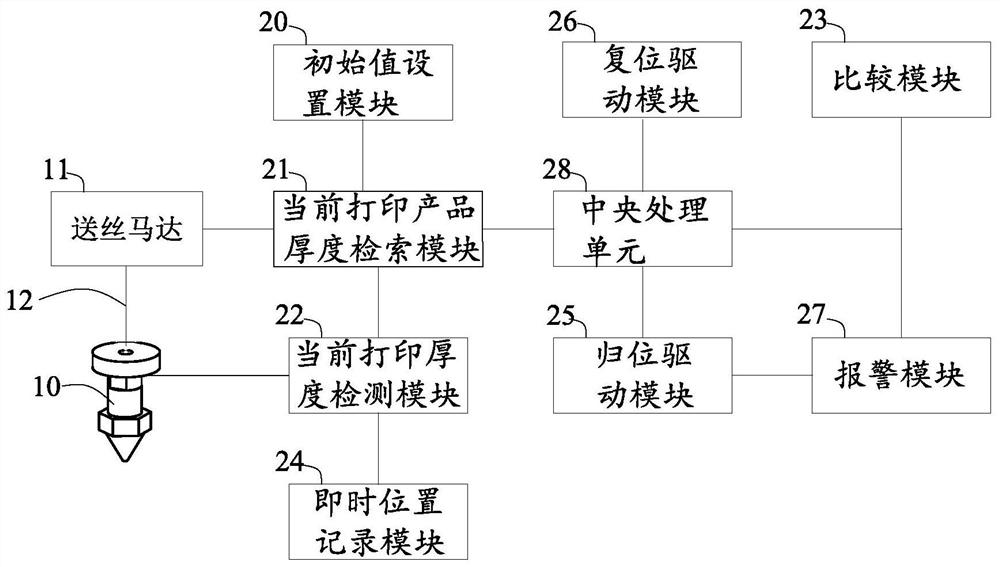

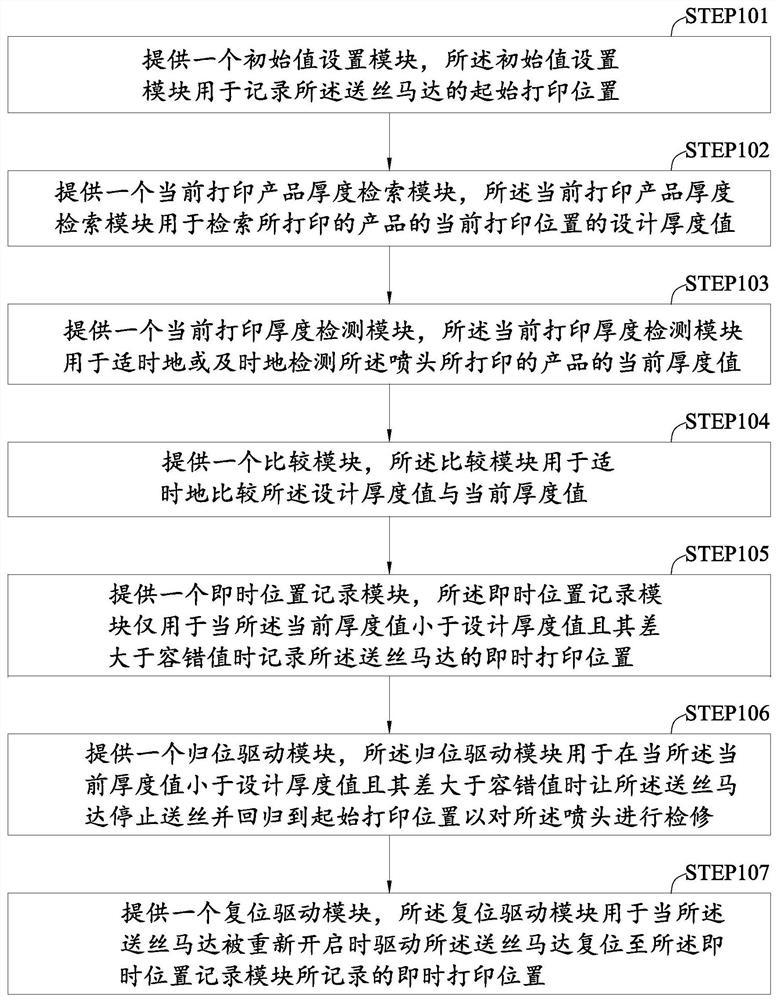

[0025] Such as Figure 1 to Figure 2 As shown, it is a functional block diagram of the high-precision nozzle clogging detection and processing system provided by the present invention. The high-precision nozzle clogging detection and processing system is used in a 3D printer. As known to those skilled in the art, the 3D printers all include a nozzle 10, a printing wire 12 passing through the nozzle 10, and a feeder that drags the printing wire 11 and drives the nozzle 10 to move. wire motor11. It can be understood that the structure and working principle of the spray head 10 and the wire feeding motor 11 should be the prior art, and will not be described in detail here. The high-precision nozzle clogging detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com