Gas stove burner and cooking bench assembly

A technology for gas stoves and cooktops, which is applied in the field of gas stove tops and cooktop components, and components of gas appliances. It can solve the problems of affecting production efficiency, difficulty in air tightness detection, and complicated assembly, etc., to achieve air tightness The detection is fast, the internal cleaning is fast and the maintenance is fast, and the effect of saving installation man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

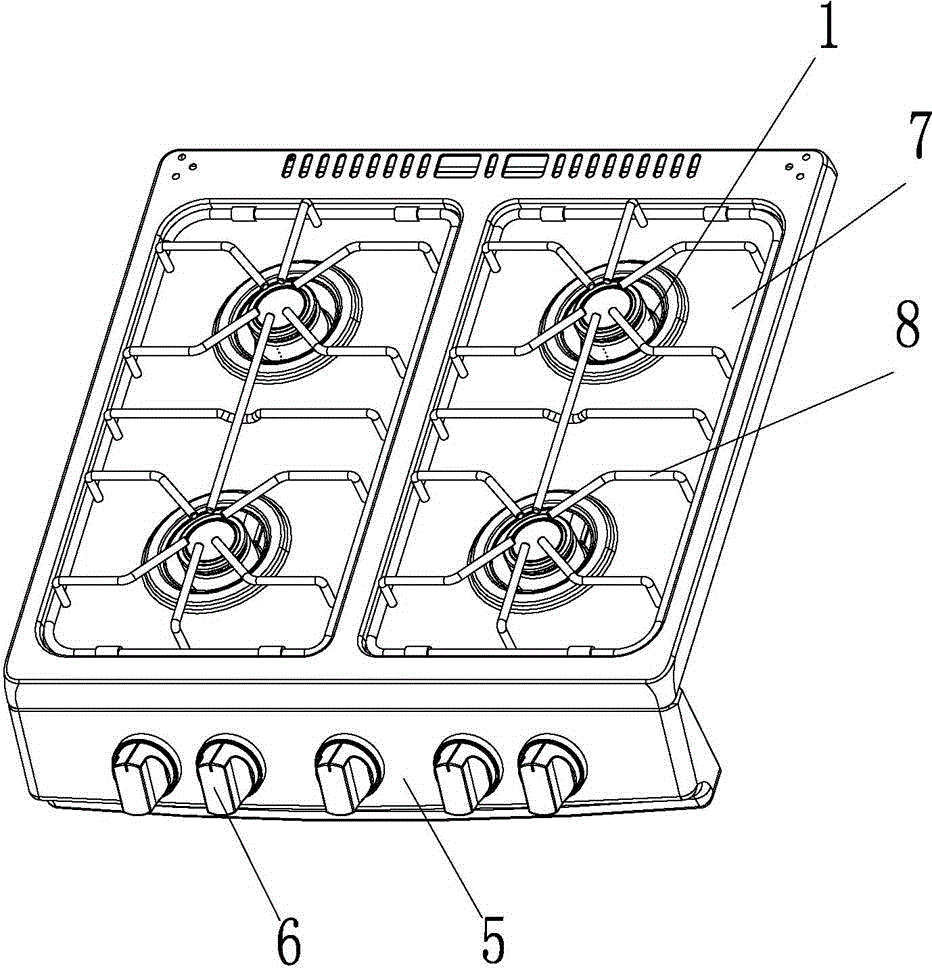

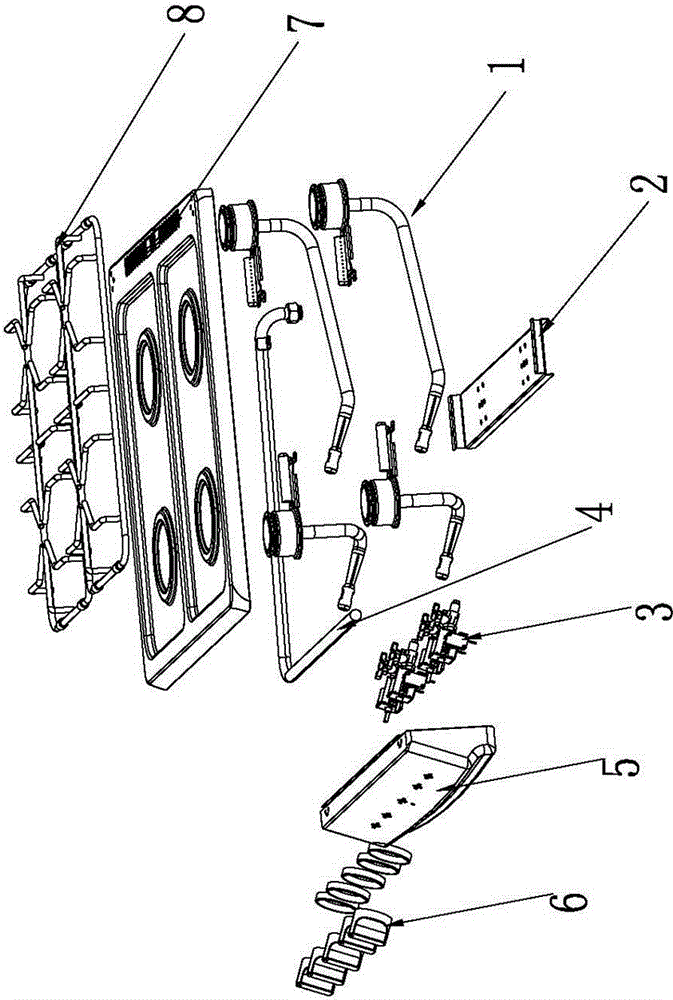

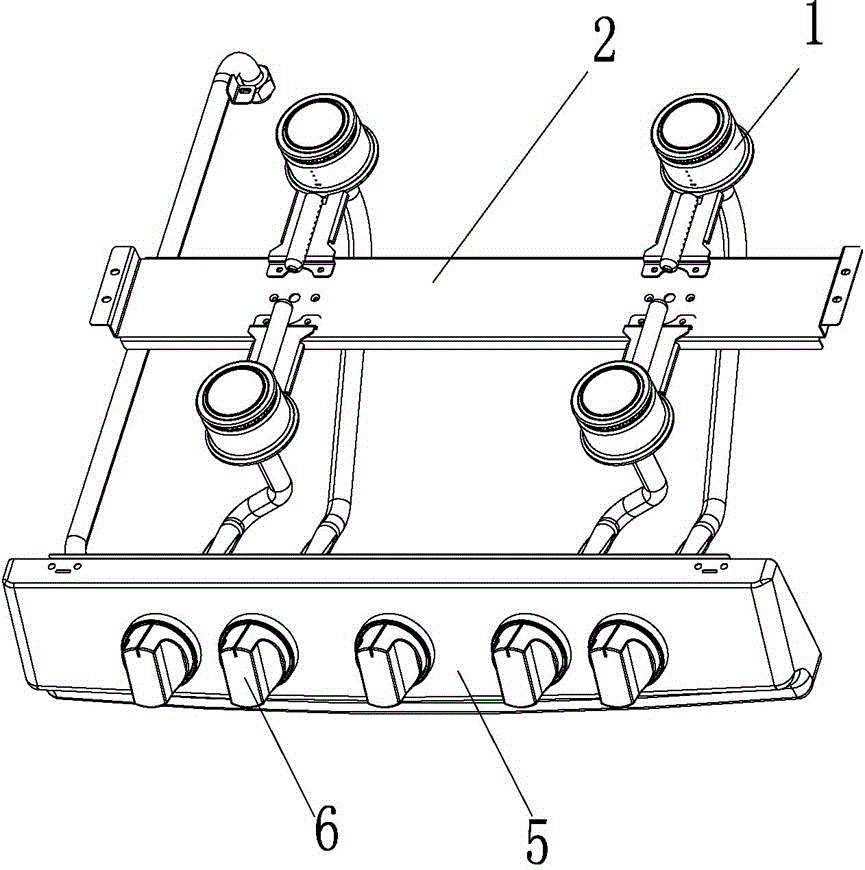

[0023] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a gas burner and cooktop assembly, which consists of a burner 1, a burner support 2, an external air intake valve body 3, a main gas pipe 4, a control panel 5, a knob 6, a cooktop plate 7 and Several parts such as pot support 8 are assembled.

[0024] Wherein, an injection tube 11 is connected to the furnace head 1 .

[0025] The burner bracket 2 is located below the burner 1 and supports the burner 1 .

[0026] One end of the external intake valve body 3 is inserted into the beginning of the injection pipe 11 of the burner 1 , and the other end is connected to the main gas pipe 4 . The external intake valve body 3 is assembled on the control panel 5 .

[0027] The knob 6 is inserted into the external intake valve body 3 and can control the external intake valve body 3 .

[0028] The stove top 7 is covered on the top of the burner support 2 , and the stove 1 is embedded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com