Reinforced beam assembly for instrument panel

A technology for reinforcing beams and instrument panels, applied in the field of reinforcing beam assemblies, can solve the problems of insufficient connection firmness, inconvenient disassembly of instruments, loose instruments, etc., and achieve the effect of improving installation efficiency and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

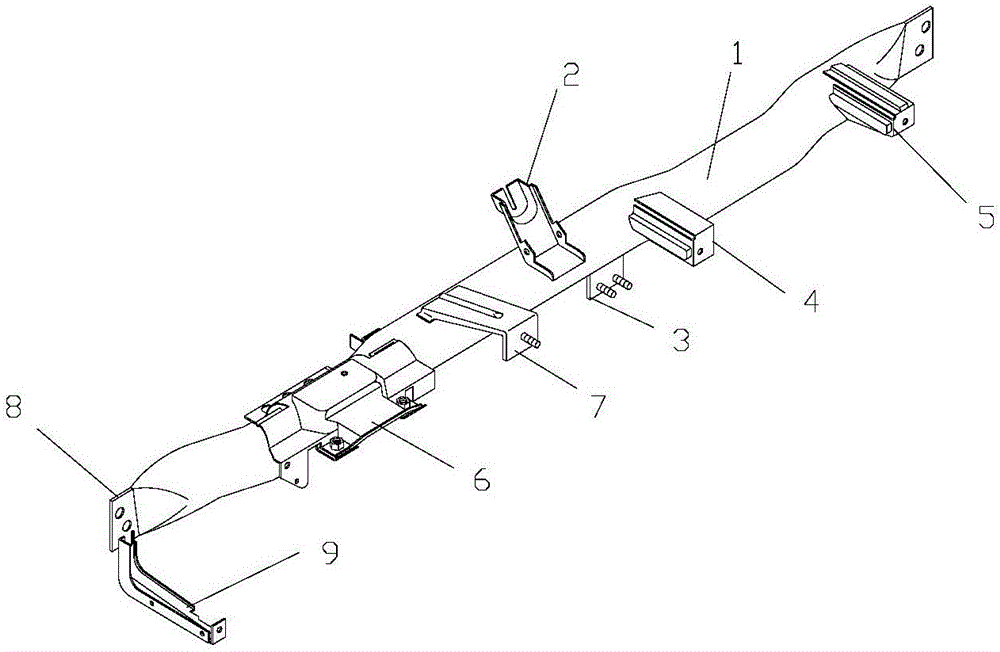

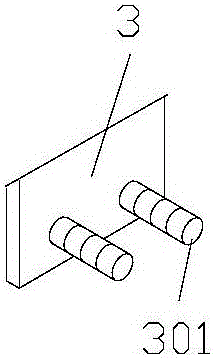

[0032] A reinforcement beam assembly for an instrument panel, comprising a support plate 1, fixed blocks 8 are arranged at both ends of the support plate 1, positioning holes 11 are opened on the fixed block 8, and the fixed block on the left side 8 is connected with a guide frame 9, the guide frame 9 includes a first member 901, and a second member 902 parallel to the first member 901, the head of the first member 901 and the second member 902 The two parts are connected with the fixed block 8, and the two are connected through the connecting bar 903, and the limit block 904 is connected at the end thereof, and a positioning hole is opened on the first member 901 and the limit block 904 11.

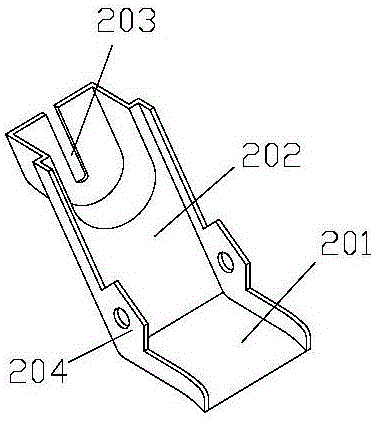

[0033] A bracket 2 is provided in the middle of the support plate 1, the bracket 2 includes a base 201, one end of the base 201 is connected with a slant plate 202, the slant plate 202 is 60° to the base 201, Both sides of the base 201 and the slant plate 202 are jointly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com