Automatic needle mounting machine

A needle loading machine and automatic technology, which is applied in the field of bearing processing, can solve the problems that the installation position of rollers or needle rollers cannot be guaranteed accurately, and achieve the effects of improving installation accuracy and efficiency, facilitating automatic needle loading, and reducing collision friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

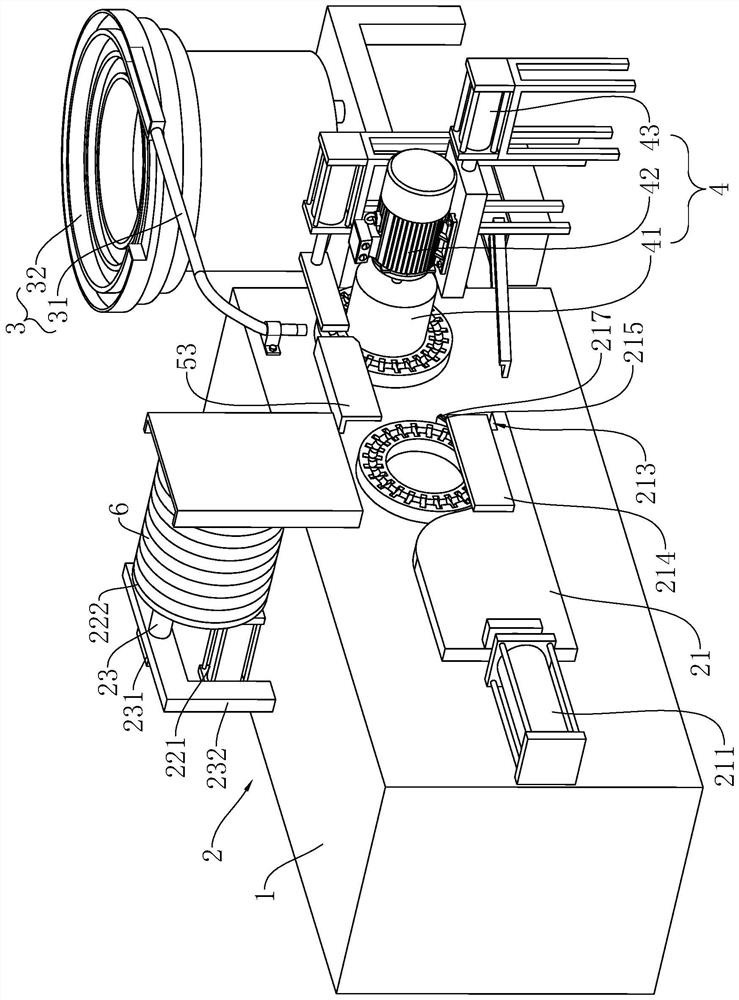

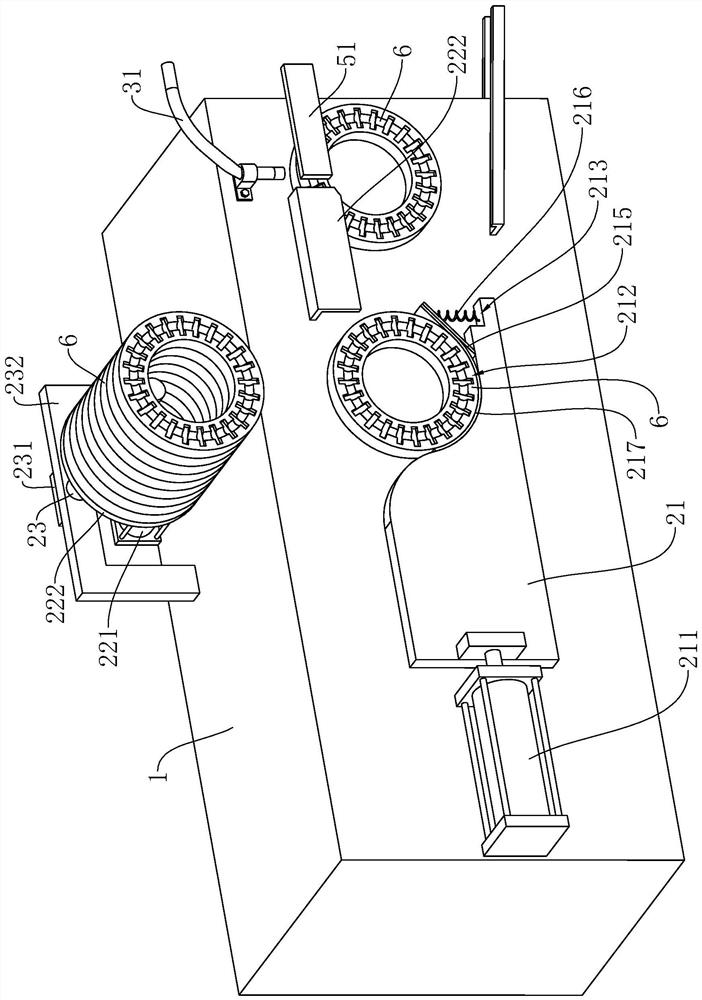

[0033] The following is attached Figure 1-Figure 2 The application is described in further detail.

[0034] The embodiment of the present application discloses an automatic needle loading machine. refer to figure 1 and figure 2 , an automatic needle loading machine, comprising a base 1, the base 1 is provided with a first feeding mechanism 2 for supplying the bearing body 6, the first feeding mechanism 2 includes a baffle 22 arranged in parallel on one side of the base 1, And the second driving member 221 arranged on the top surface of the base 1 and perpendicular to the baffle 22, the second driving member 221 can be a cylinder in the embodiment of the present application, and the spacing width between the baffle 22 and the side of the base 1 is larger than that of the bearing The thickness of the main body 6, the end of the second driver 221 is connected with a partition 222, and a number of bearing bodies 6 are clamped between the partition 222 and the baffle 22, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com