Bellows sleeve

A technology of corrugated pipes and pipe sleeves, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of corrugated pipe damage, time-consuming and laborious, etc., to avoid damage to corrugated pipes, improve installation accuracy and The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

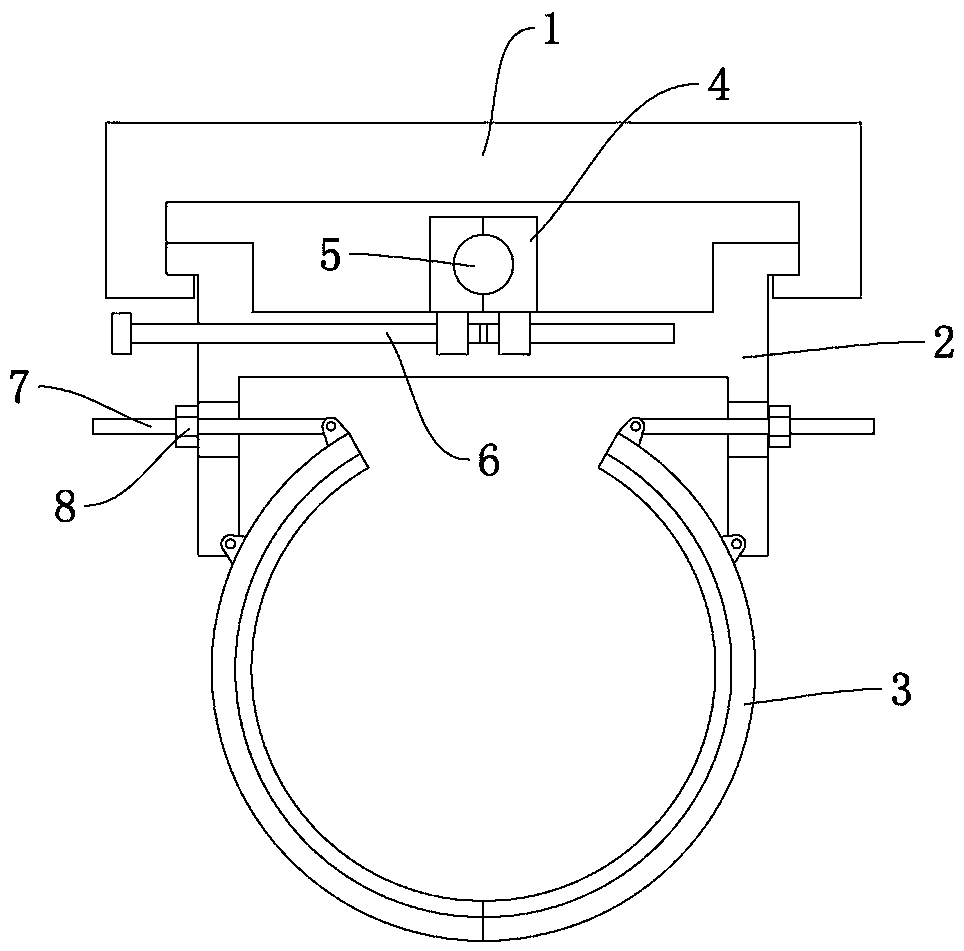

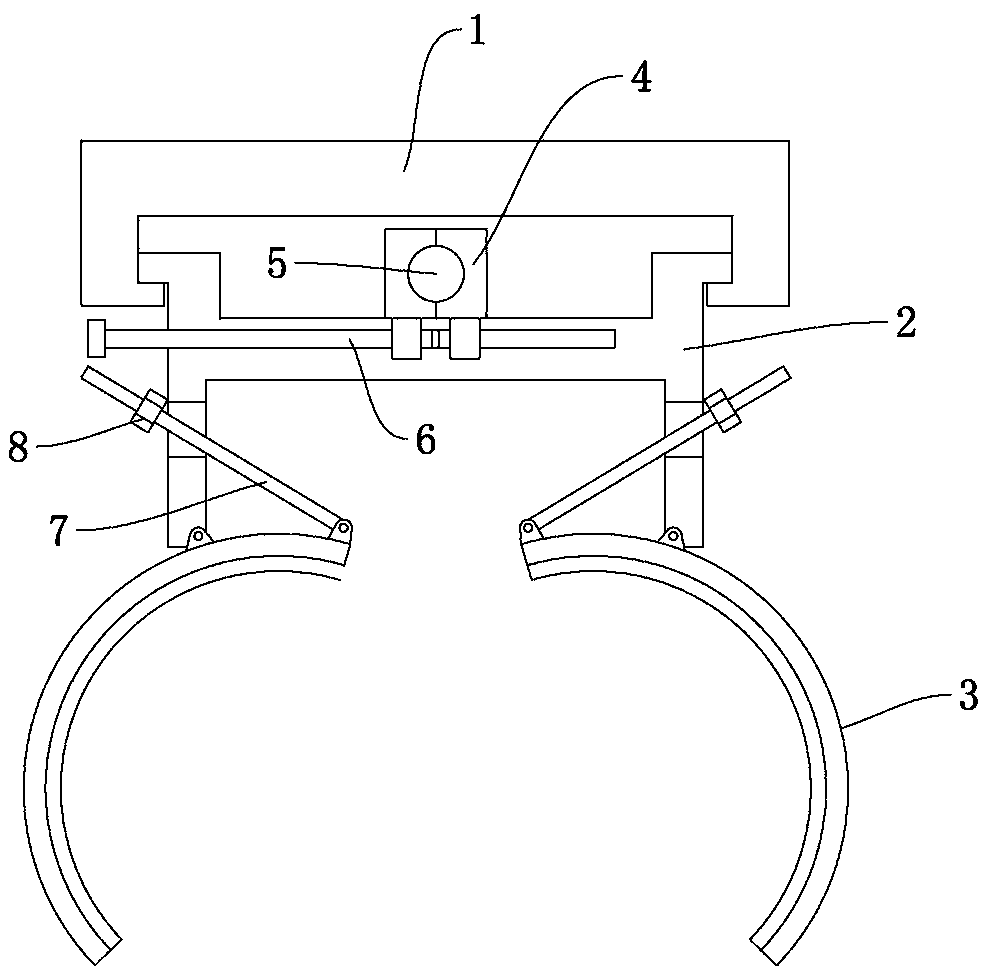

[0020] Embodiment 1: as figure 1 and figure 2 As shown, a bellows sleeve includes a bracket 1, a movable seat 2, and two arc-shaped sleeves 3 formed by buckling each other. The sleeves 3 are symmetrically distributed on the left and right sides of the center line of the bellows. The inner wall of the sleeve body 3 is provided with a clamping groove matching the crest of the bellows.

[0021] The sleeve body 3 is hinged on the movable seat 2 and rotates relative to the movable seat 2 in the radial direction of the bellows. The movable seat 2 is provided with a first control assembly for controlling the rotation of the sleeve body 3 to open or close the sleeve. The first control assembly includes a first screw rod 7 and an adjusting nut 8, and the movable base 2 is provided with a vertically arranged long slot, and the first screw rod 7 is inserted into the long slot, and the first screw rod 7 One end is hinged on the sleeve body 3, and the other end is screwed with an adjus...

Embodiment 2

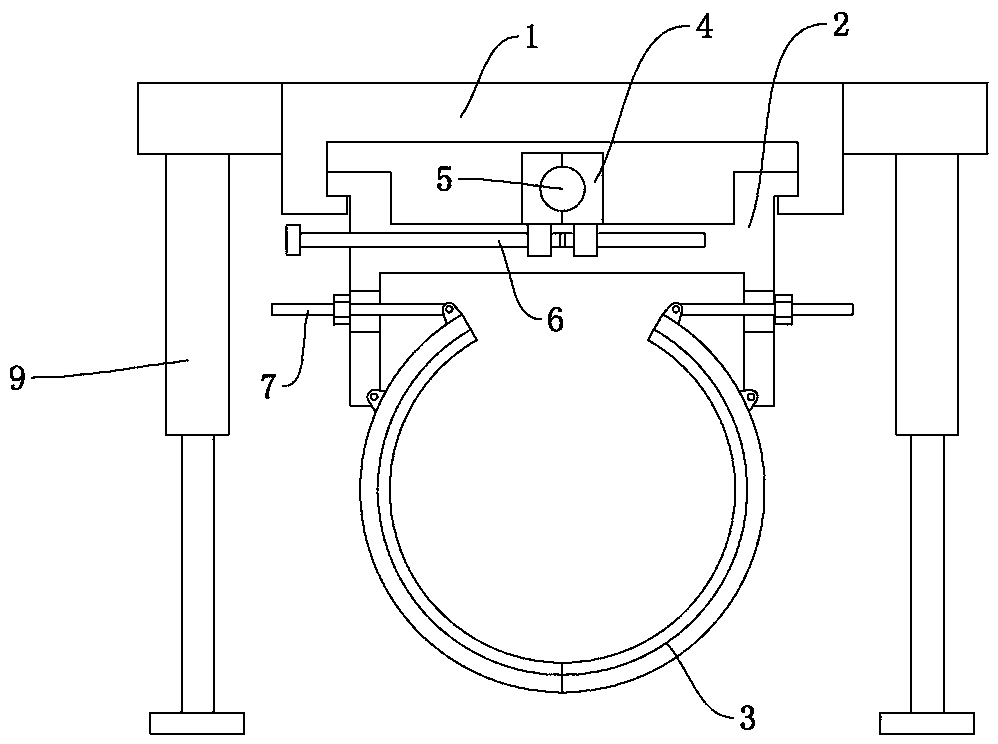

[0024] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 is that support arms 9 are provided on the left and right sides of the bracket 1, and the support arms 9 are telescopic structures.

[0025] A method for using a bellows sleeve, comprising the following steps: 1) rotating the sleeve body 3 to fully open the two sleeve bodies 3; 2) inserting the bellows tube between the two sleeve bodies 3, and The sleeve body 3 is folded and clamped on the surface of the bellows to form a sleeve, and then the adjusting nut 8 is installed on the first screw 7 to fix the sleeve body at the corresponding position; The sleeve is raised to the corresponding height, so that the tube center of the clamped bellows is aligned with the tube center of the installed original tube; 4) Rotate the screw rod 5 through the handle, so that the movable seat 2 and the sleeve body 3 drive the bellows shaft Slowly insert the bellows into the socket of the original pipe to complete the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com