Power vehicle high temperature test device and test method

The technology of a test device and test method, which is applied in the field of power supply vehicles, can solve the problems of high temperature test of power supply vehicles, and achieve the effect of ensuring the smooth completion and avoiding the operation of adding and subtracting loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

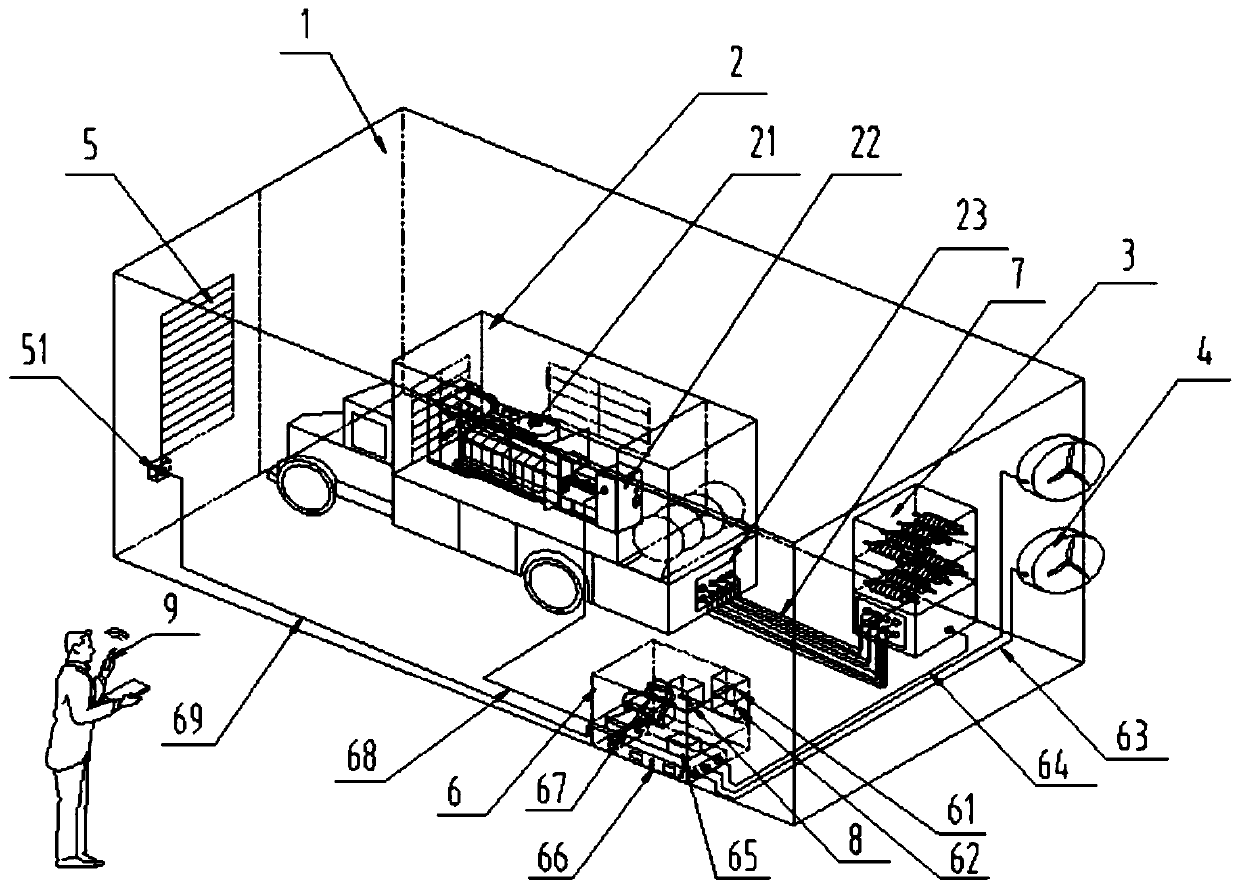

[0032] Such as figure 1 As shown, a power supply vehicle high temperature test device includes a test room 1 and a power supply vehicle 2. The test room 1 is provided with a test cabinet 6 and an adjustable resistance load cabinet 3; the power supply vehicle 2 includes a generator set 21 and a power distribution cabinet 22. and the output junction box 23, the power distribution cabinet 22 is connected with the test cabinet 6 through the cable 68, and the output junction box 23 is connected with the adjustable resistance load cabinet 3 through the cable 7; the test room 1 also includes the air intake shutter 5 and the exhaust fan 4, the air intake shutter 5 and the exhaust fan 4 are connected to the test cabinet 6 through the control line three 69 and the control line one 63 respectively; the test cabinet 6 is provided with a voice input m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com