Quilt core, temperature control quilt and production process of temperature control quilt

A production process and technology for quilts, applied in household appliances, bedspreads, applications, etc., can solve the problems that affect the sleep quality of users, cannot be recycled and reused, and the quilt core cannot be cleaned, etc., and achieves light weight, overall light weight, and overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The first purpose of this embodiment is achieved through the following implementation methods:

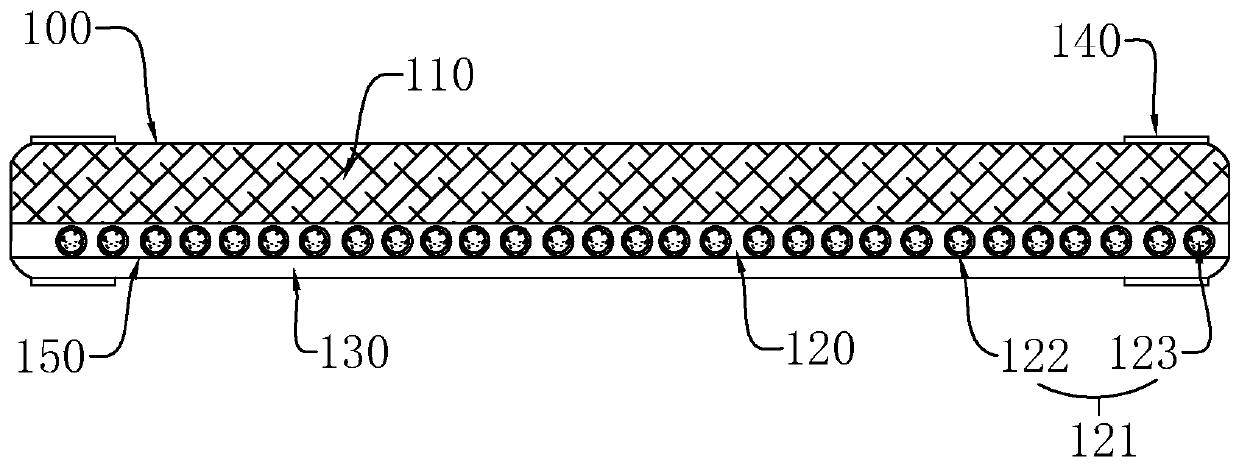

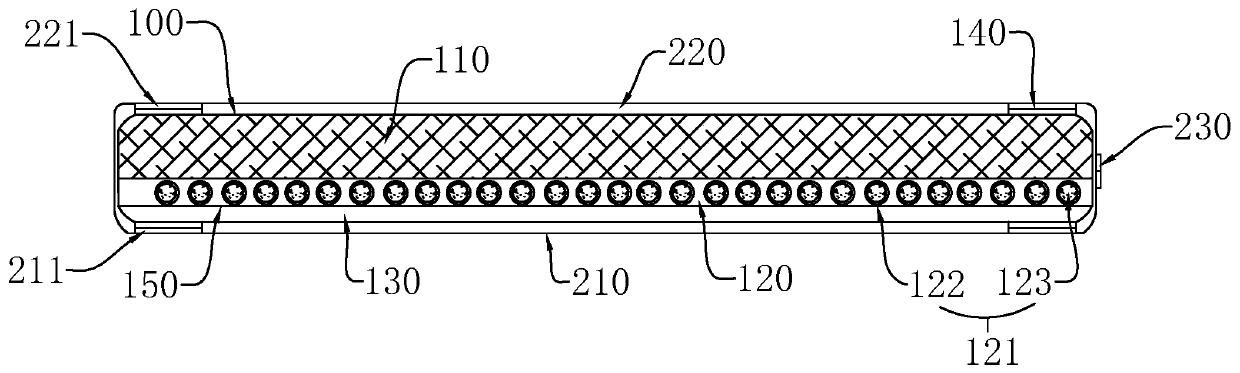

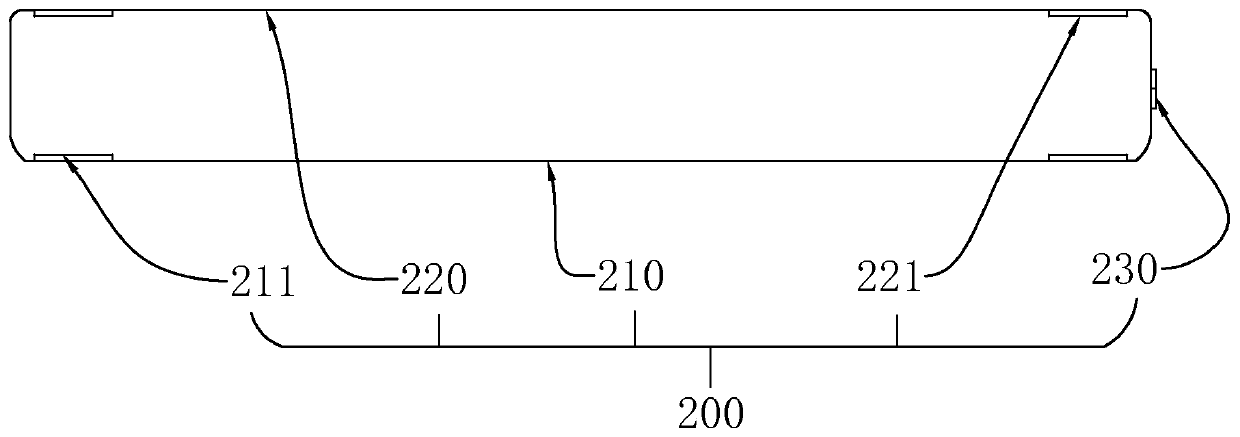

[0051] refer to figure 1 , a quilt core, comprising an outer wrapping layer 100, the outer wrapping layer 100 is provided with a thermal insulation layer 110 and a temperature control layer 120, one side of the thermal insulation layer 110 is connected to one side of the temperature control layer 120, and the other side of the temperature control layer 120 One surface is connected to the drying layer 130 , the temperature control layer 120 is provided with a temperature control component 121 , and the four sides of the wrapping layer 100 are provided with connecting edges 140 above and below. The temperature control layer 120 can control the temperature inside the quilt. The temperature control component 121 contains a phase change material. When the temperature inside the quilt core is high, it absorbs heat, and when the temperature inside the quilt is low, it releases heat t...

Embodiment 2

[0067] refer to Figure 4 , wherein the temperature control component 121 is several layers of woven fabric layers 124 of Tencel fibers soaked in PCM liquid, which are superimposed and connected to each other. The performance of Tencel fiber is as above, it has good moisture absorption, PCM liquid can be soaked in Tencel fiber woven cloth, so that it has the function of temperature control.

[0068] The rest of this embodiment is the same as Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com