An automatic temperature control gas valve

A technology of gas valves and electric control valves, which is applied in the direction of controlling combustion, valve details, valve devices, etc., can solve the problems of gas heater ignition device loss and reduce service life, and achieve simple structure, prolong service life and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

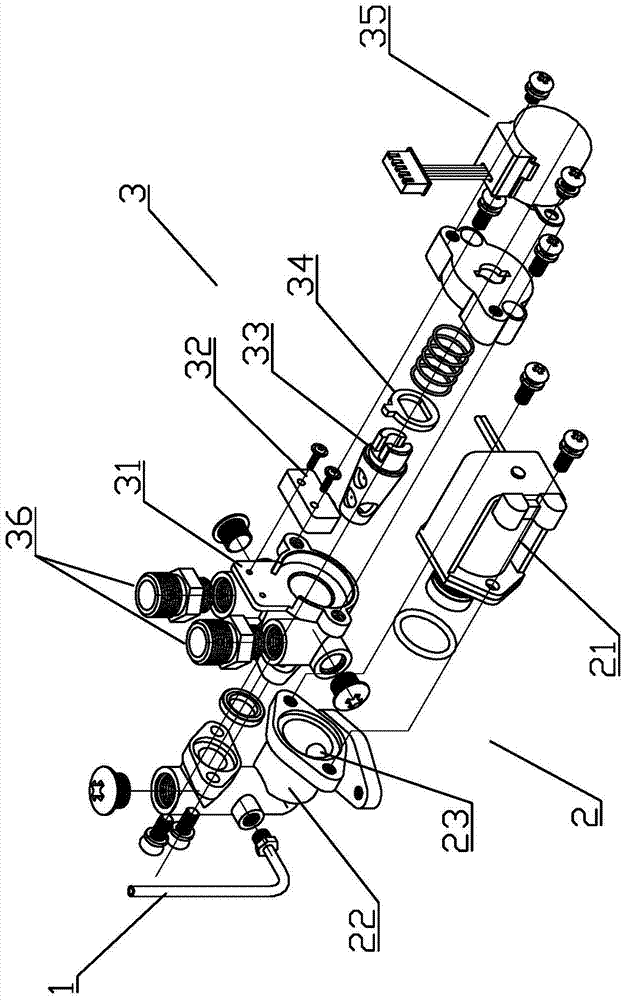

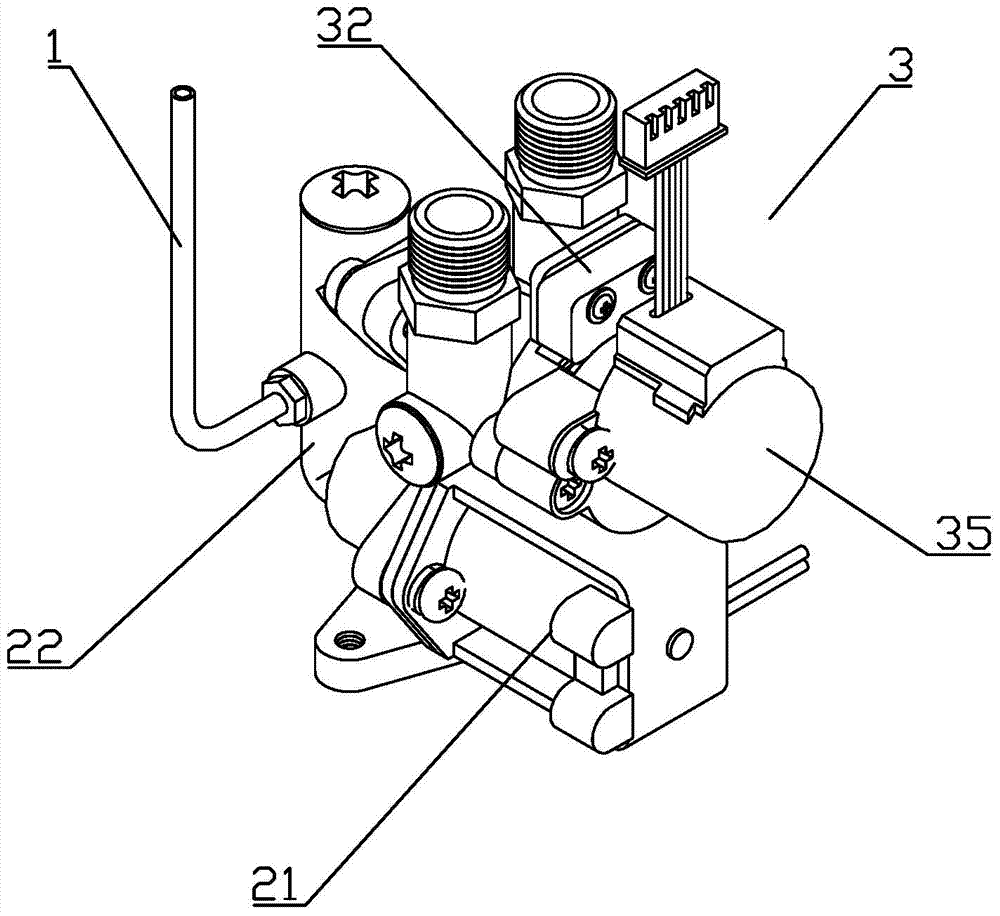

[0014] Reference figure 1 with figure 2 , An automatic temperature control gas valve, comprising a gas source inlet 23, a solenoid valve 2, a mother fire nozzle 1, an electronic control valve 3, at least one main fire outlet 36, the solenoid valve 2 includes a solenoid valve body 21 and The solenoid valve seat 22 and the gas source inlet 23 are used as the air inlet of the solenoid valve seat 22. The air inlets of the mother fire nozzle 1 and the electric control valve 3 are respectively connected to the air outlet of the solenoid valve seat 22. The solenoid valve body 21 controls the solenoid The valve seat 22 is connected or closed between the air inlet and the air outlet. The main fire outlet 36 serves as the air outlet of the electric control valve 3. The electric control valve 3 is used to control the opening and closing of the main fire outlet 36 and the amount of air output. The solenoid valve 2 The action with the electronic control valve 3 is controlled by the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com