Quick releasing device for gas dynamic disaster simulator stand and testing method thereof

A technology for simulating test benches and dynamic disasters, applied in measuring devices, fuel oil testing, material inspection products, etc., can solve problems such as complex equipment structure, limited simulation level, and troublesome loading and unloading of coal samples, so as to achieve accurate test results and improve the simulation level , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

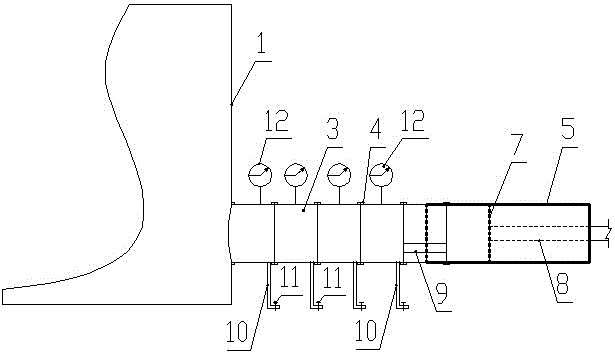

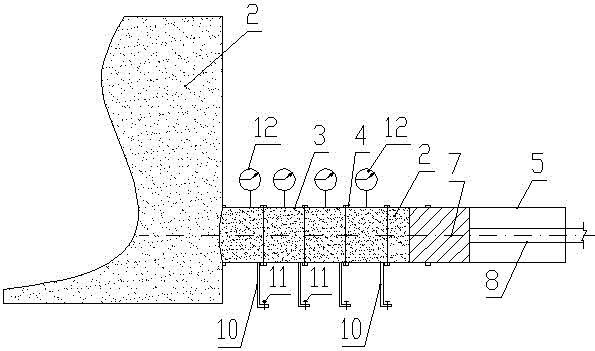

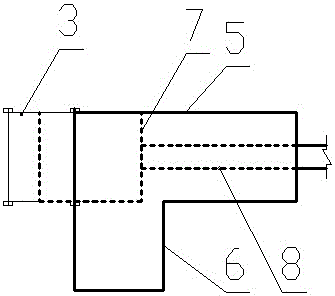

[0026] Such as figure 1 , figure 2 with image 3 As shown, the quick release device of the gas dynamic disaster simulation test bench of the present invention includes a protruding cylinder 1 filled with coal samples 2 and gas; the protruding cylinder 1 is connected with a piston cylinder 3, and the piston cylinder 3 is provided More than two, the total length of the piston cylinder 3 is the same as the thickness of the simulated field shielding coal pillar; the adjacent piston cylinders 3 are connected through the flange structure 4; the piston cylinder 3 at the end is connected through the flange structure 4 with loading and pressure relief cylinder 5, one end of the loading and unloading cylinder 5 connected to the piston cylinder 3 is connected with a protruding cylinder 6, and the protruding cylinder 6 and the loading and unloading cylinder 5 are perpendicular to each other; the free ends of the protruding cylinder 6 and the loading and unloading cylinder 5 are both Op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com