Power supply device

A technology of power supply equipment and power supply unit, which is applied in the direction of data processing power supply, measuring device, measuring flow rate/mass flow rate, etc. It can solve the problems of inability to move relative to each other, connectors are easy to fall off, and connection is inconvenient, so as to avoid open circuit and avoid Plug-in line short circuit, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

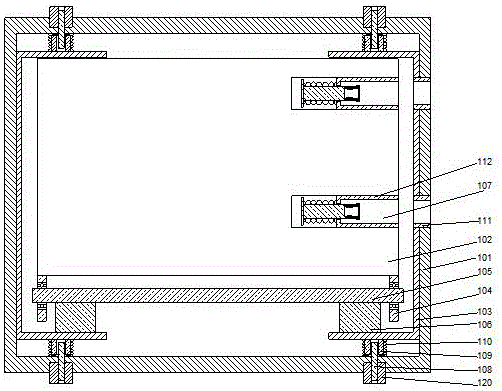

[0023] Such as figure 1 , 2 As shown, a power supply device includes a rectangular parallelepiped cover 101 and a power supply unit 102 arranged inside the cover 101, and brackets 103 are respectively provided on two opposite side walls inside the cover 101 The middle part of the bracket 103 is attached to the inner wall of the cover 101, both ends of the bracket 103 are bent inward to form a U-shaped structure, and the power supply unit 102 is clamped to the two Inside the U-shaped structure of the bracket 103, baffles 104 are provided on the lower ends of both sides of the power supply unit 102, and a rotating shaft 105 is provided between the baffles 104, and the two ends of the rotating shaft 105 are respectively rotatably connected On the baffle 104, a support bar 106 is provided on the inner side of the bracket 103, and the rotating shaft 105 is attached to the support bar 106 to roll relative to each other. On the side wall of the cover 101 The power supply unit 102 is p...

Embodiment 2

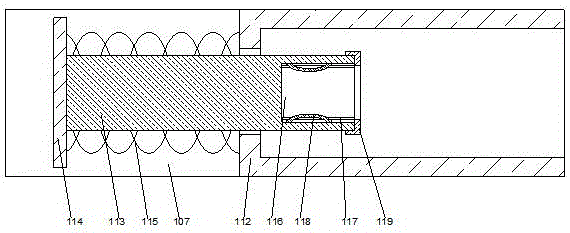

[0026] In this embodiment, on the basis of embodiment 1, in order to prevent the insertion depth of the joint from being unable to be controlled when the line is inserted, in this embodiment, preferably, a through hole is provided at the bottom of the metal connecting pipe 112, and A reset rod 113 is inserted into the through hole, a circular plate 114 is provided at one end of the reset rod 113 extending out of the through hole, and a reset spring 115 is sleeved on the outside of the reset rod 113. One end of the return spring 115 is attached to the end surface of the circular plate 114 facing the metal connecting tube 112, and the other end of the return spring 115 is attached to the metal connecting tube 112 facing the circular plate. The end face of the plate 114 on one side. When the connector is inserted inside the metal connecting tube, the connector and the metal connecting tube are connected to each other, so that the end of the connector is attached to the reset rod. ...

Embodiment 3

[0031] In this embodiment, in order to facilitate the installation of the positioning rod, preferably, a threaded hole is provided on the cover 101, an external thread is provided on the outer wall of the positioning rod 108, and the positioning rod 108 is threadedly connected On the cover 101. After installing the bracket on the inside of the cover, screw the positioning rod on the cover, insert the lower end of the positioning rod into the positioning tube on the bracket, and make the lower end of the positioning rod hang relative to the positioning tube. Due to the threaded connection, the depth of the positioning rod inserted into the positioning tube can be determined as required.

[0032] Further preferably, in this embodiment, in order to fix the positioning rod, preferably, one end of the positioning rod 108 penetrates the outside of the cover body 101, and the positioning rod 108 extends out of the cover body 101 A fixed sleeve 120 is provided on one side, and the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com