360-degree full-angle wide-area scanning head

A scanning head and wide-area technology, which is applied in the field of 360-degree full-angle wide-area scanning head, can solve the problems that the accuracy and speed of the galvanometer cannot be improved, the quality of the galvanometer increases, and the scanning accuracy and speed cannot be improved, so as to improve the scanning accuracy And the effect of speed and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

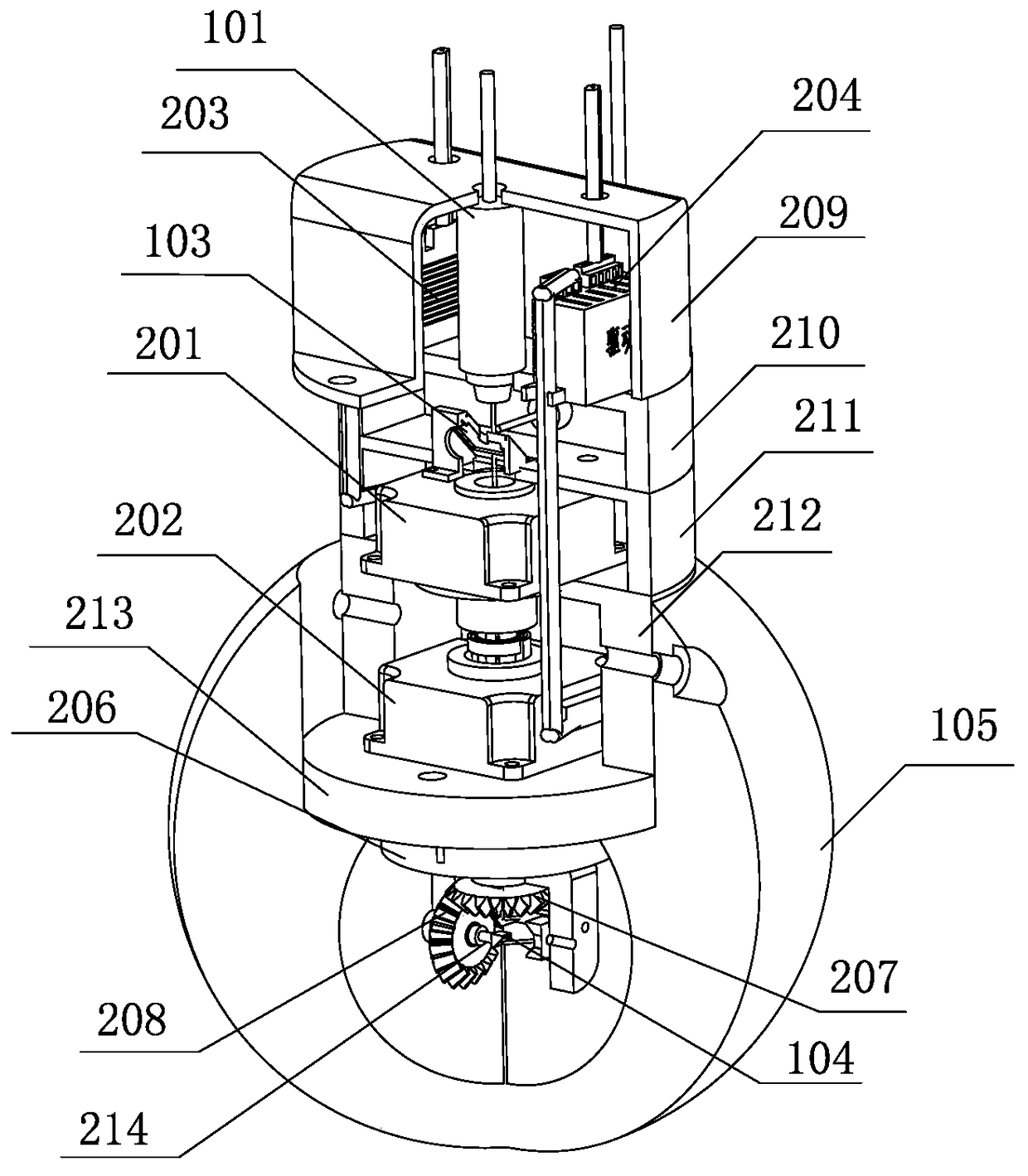

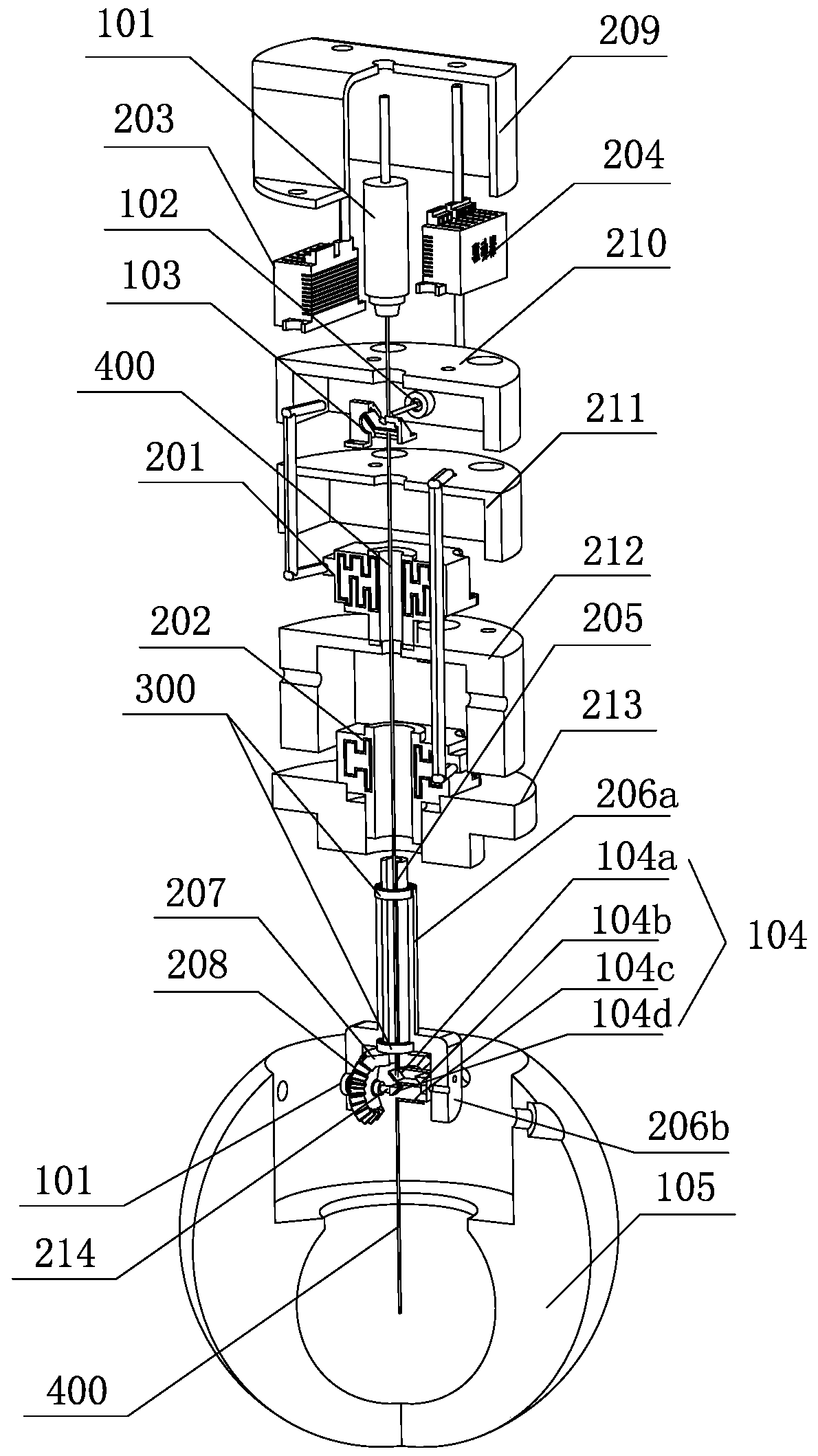

[0043] like Figures 1 to 7 As shown, the 360-degree full-angle wide-area scanning head disclosed in Embodiment 1 of the present invention is composed of a photoelectric component 100 and a driving component 200;

[0044] The photoelectric component 100 includes a vertical light source 101, a horizontal light source 102, a half mirror 103, a full mirror group 104 and a field mirror 105; Above the half-mirror 103, the horizontal light source 102 is arranged on the side of the half-mirror 103, and the full mirror group 104 is arranged on the half-mirror 103 below; the vertical light source 101 and the horizontal light source 102 are laser light sources;

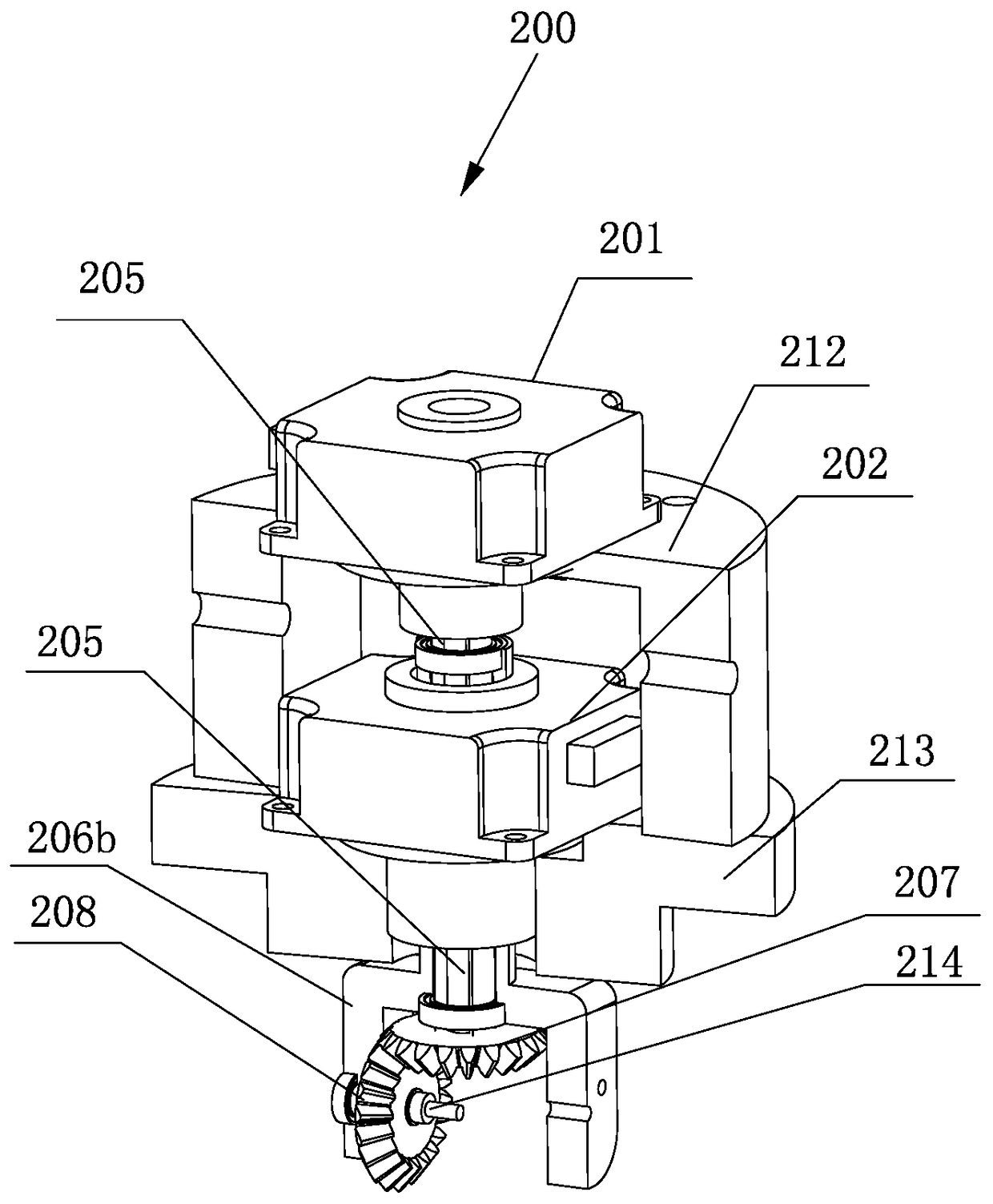

[0045] The drive assembly 200 includes a vertical drive motor 201, a horizontal drive motor 202, a first driver 203, a second driver 204, a vertical rotation shaft 205, a horizontal rotation bracket 206, a vertical rotation bevel gear 207 and a horizontal rotation bevel gear 208 ; The vertical drive motor 201, the horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com