Capacitor voltage fluctuation suppression method for modular multilevel converter at low frequency and low voltage

A modular multi-level, capacitive voltage technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of increasing converter cost, converter design problems, and affecting motor insulation Design and other issues to achieve the effect of improving work performance, solving control problems, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

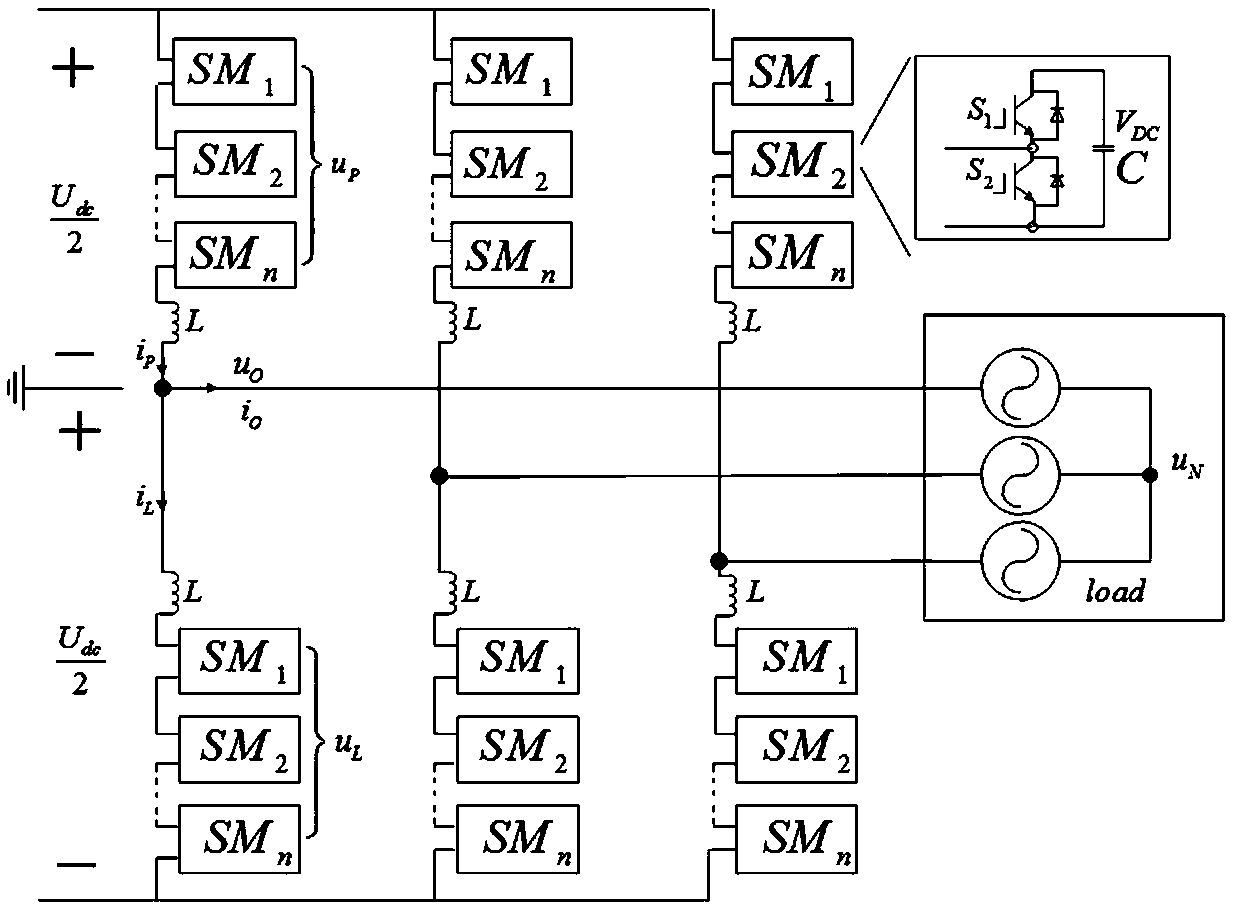

[0022] Such as figure 1 As shown, it is a modular multilevel converter structure. In conventional modular multilevel converter control, in order to share the output power with the upper and lower bridge arms, the upper and lower bridge arms adopt a symmetrical operation mode, and the output voltage of the upper and lower bridge arms is

[0023]

[0024]

[0025] where U dc is the DC side voltage, U o It is the maximum value of AC voltage on the output side. Similarly, the output current of the upper and lower bridge arms is,

[0026]

[0027]

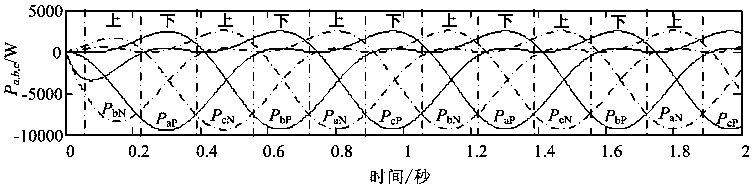

[0028] where I cir is the circulation flow. Therefore, when the converter is running, the power of the upper and lower bridge arms is respectively,

[0029]

[0030]

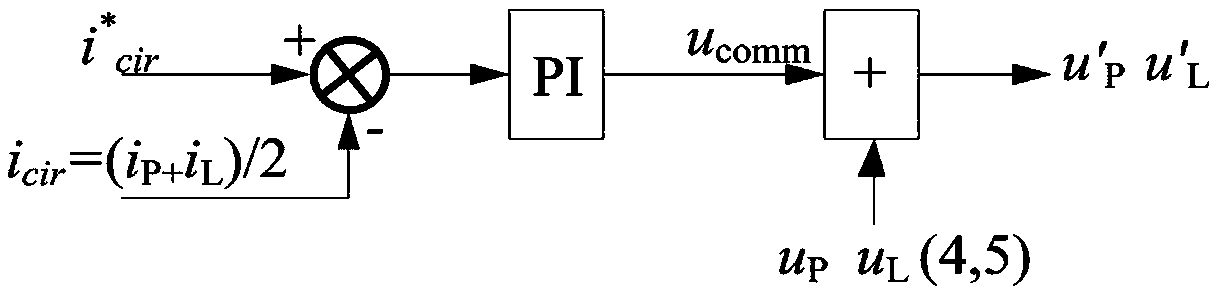

[0031] It can be seen from the above that when the motor is driven at low speed, U O ≈0, there are large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com