Inductive Load Voltage Pulse Width Modulation Degaussing Circuit

A pulse width modulation and degaussing circuit technology, applied in electrical components, pulse technology, electronic switches, etc., can solve the problems of large power consumption of Zener diodes or resistors, inability to quickly release inductive loads, breakdown of Zener diodes, etc. Achieve power saving, low power consumption and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

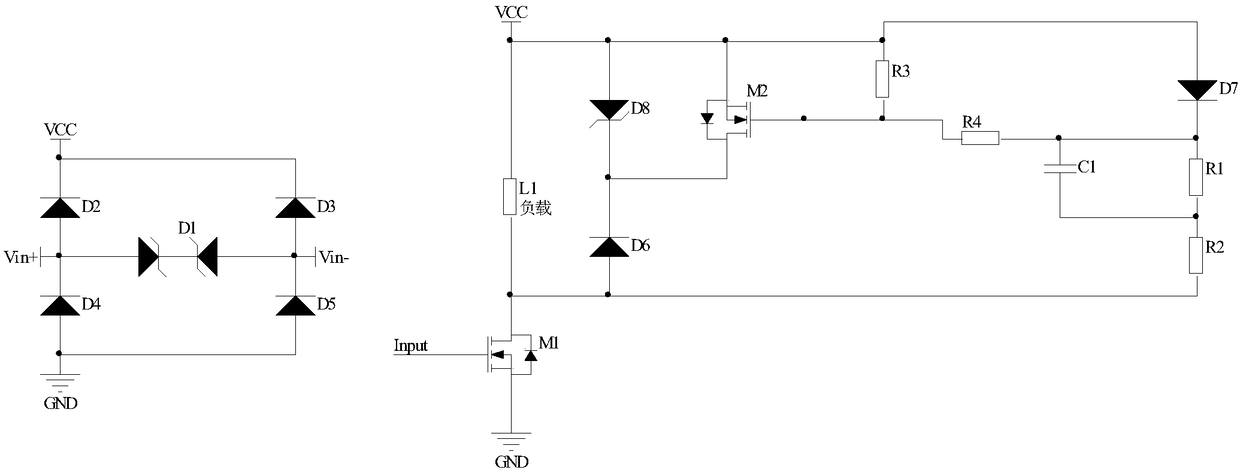

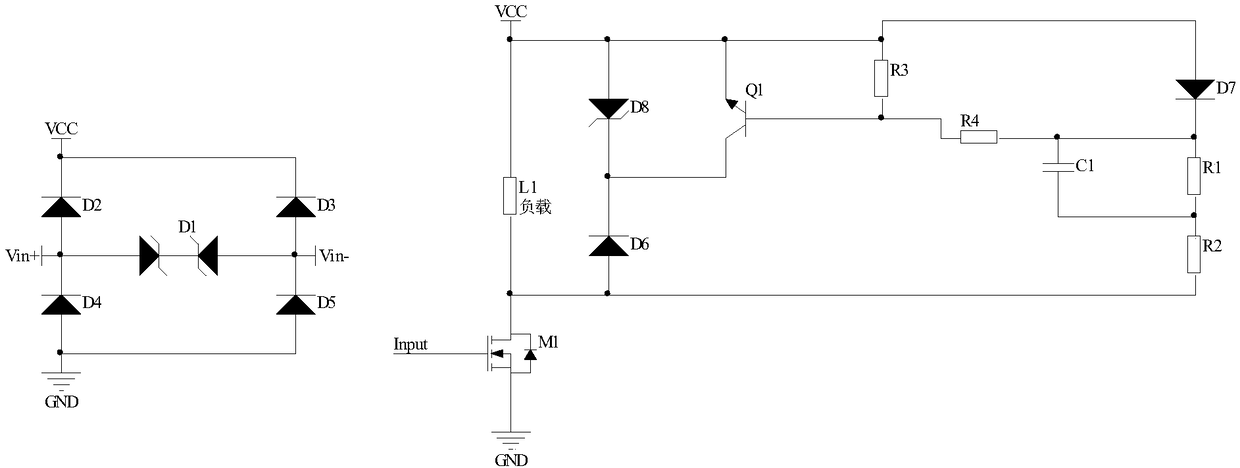

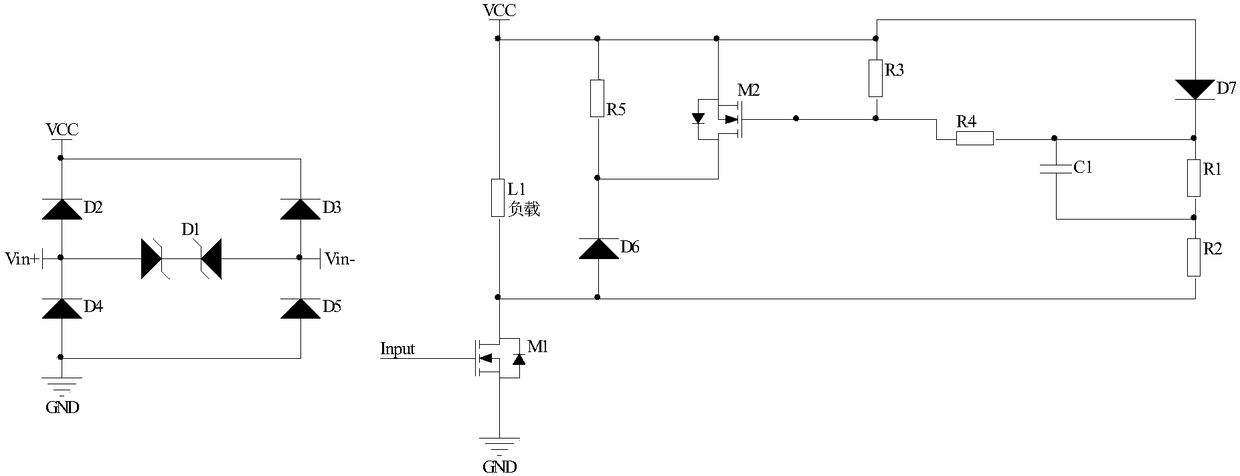

[0034] like figure 1 , figure 2 Shown, the present invention comprises input protection rectification circuit and demagnetization main circuit; Input protection rectification circuit comprises rectification diode D2, rectification diode D3, rectification diode D4, rectification diode D5 and bidirectional TVS tube or bidirectional voltage regulator diode D1; Demagnetization The main circuit includes NMOS tube M1, NMOS tube M2 or triode Q1, load L1, Zener diode D8, diode D6, diode D7, capacitor C1, resistor R1, resistor R2, resistor R3, resistor R4; one end of load L1 is connected to The anode of Zener diode D8, the source of NMOS transistor M2 or the emitter of transistor Q1, one end of resistor R3 and the anode of diode D7 are connected to VCC, and the other end of load L1 is respectively connected to the anode of diode D6 and the drain of NMOS transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com