Gasket assembly with half stop and method of making the same

A technology of gasket and stopper layer, applied in the field of gasket assembly with half stopper and its manufacture, capable of solving problems such as protrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

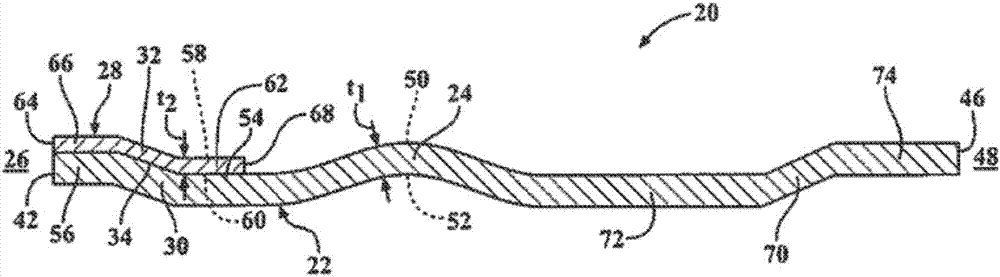

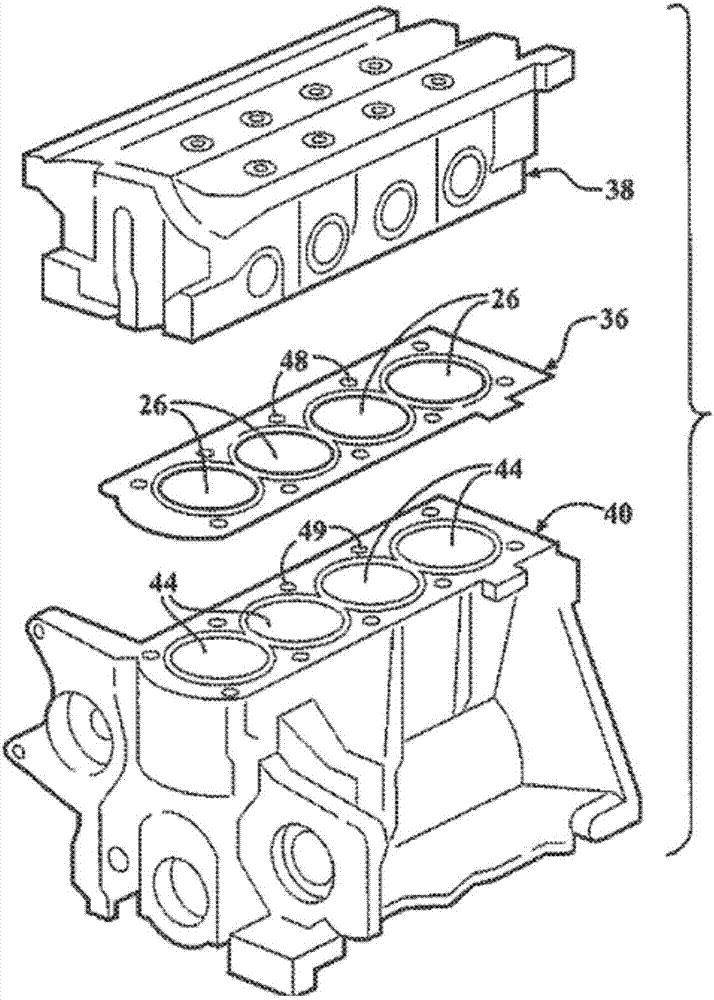

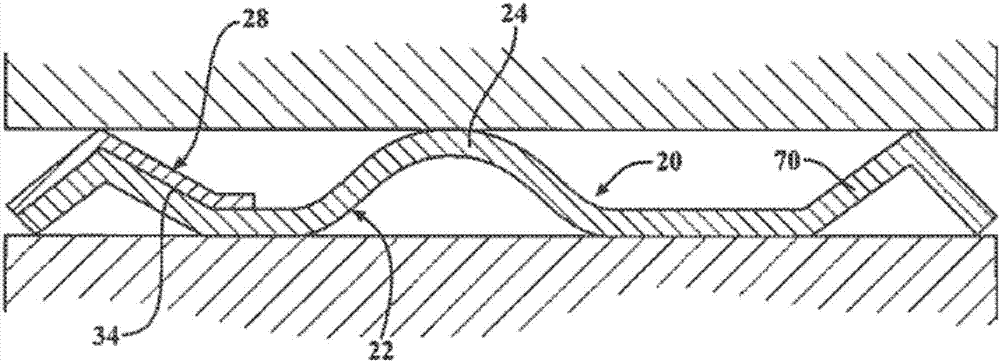

[0014] see figure 1 , generally shows a gasket assembly 20 for providing a gas and fluid seal between two components. The gasket assembly 20 includes a functional layer 22 including an entire protrusion 24 spaced apart from a first opening 26 such as a combustion chamber opening, and a stopper layer 28 disposed between the first opening 26 and the entire protrusion. Between 24. Each of the stop layer 28 and the functional layer 22 includes a half protrusion 30 , 32 located between the first opening 26 and the entire protrusion 24 , which together are referred to as a half stop 34 . Half-stop 34 is formed in a single process step and limits compression across protrusion 24 when gasket assembly 20 is compressed between the two components. As a result, gasket assembly 20 enables high strength, dynamic embossing technology with a substantially single layer and single process step. exist figure 2 An exemplary cylinder head gasket 36 including the gasket assembly 20 is shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com