Rapid pressure relief detection device for rubber seals

A technology of rubber seals and detection devices, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of high cost, achieve low cost, easy operation, and protect personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further detailed description will be given below in conjunction with the embodiments of the present invention and the accompanying drawings.

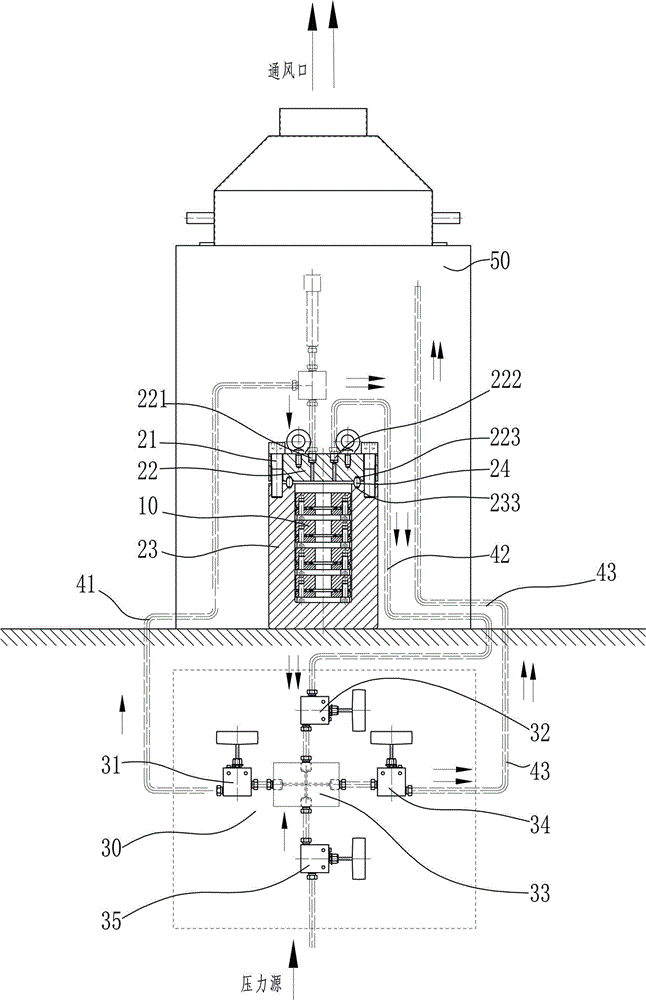

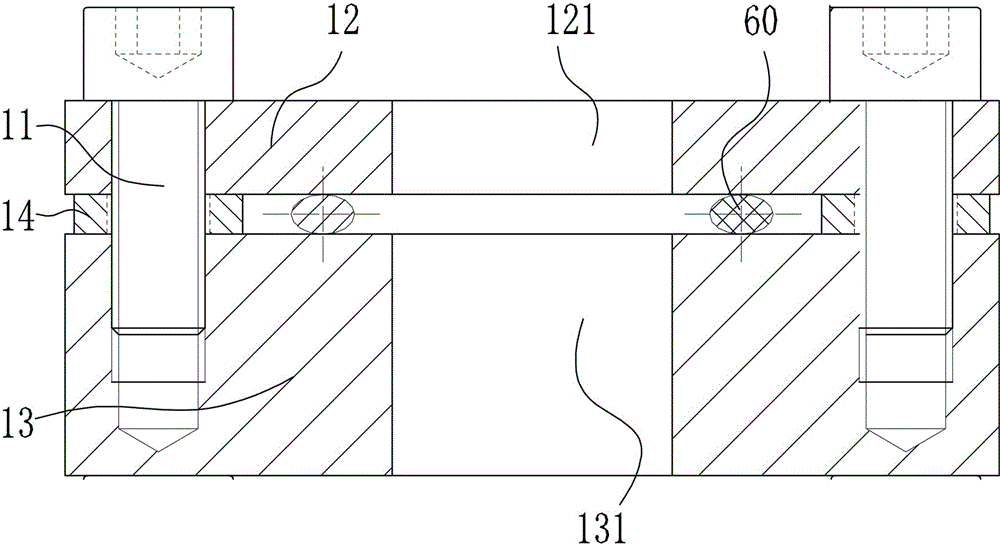

[0012] The rapid pressure release detection device for rubber seals as shown in the accompanying drawings includes a tooling 10, a test container and a valve group 30, wherein the tooling 10 is composed of a first bolt 11 connecting a lower cover 13 and an upper cover 12, and the lower cover 13 and the upper cover 12 is provided with central holes 131 and 121. The rubber seal 60 to be tested is placed on the lower cover 13, and the gasket 14 is placed on the screw hole of the lower cover 13 at the same time, then the upper cover 12 is placed on the rubber seal 60 and the gasket 14, and the first bolt 11 is screwed. Insert the lower cover 13 screw holes until the upper cover 12 is pressed tightly, and the rubber seal 60 is compressed at the same time. The gasket 14 is located between the lower cover 13 and the upper cover 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com