Daily use paper and manufacturing method thereof

A technology for household paper and single-sheet paper, applied in chemical instruments and methods, household appliances, paper/cardboard layered products, etc., can solve the problems of poor quality, increased overlap rate, loose voids, etc., to increase the thickness of the stack , the effect of reducing the overlap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

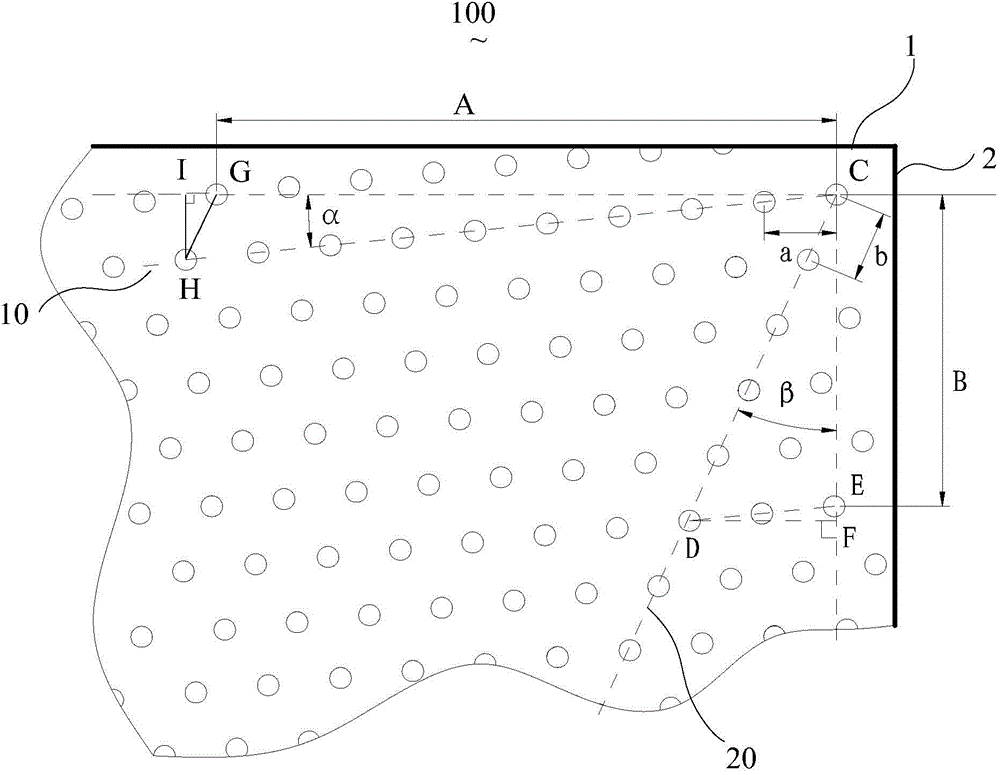

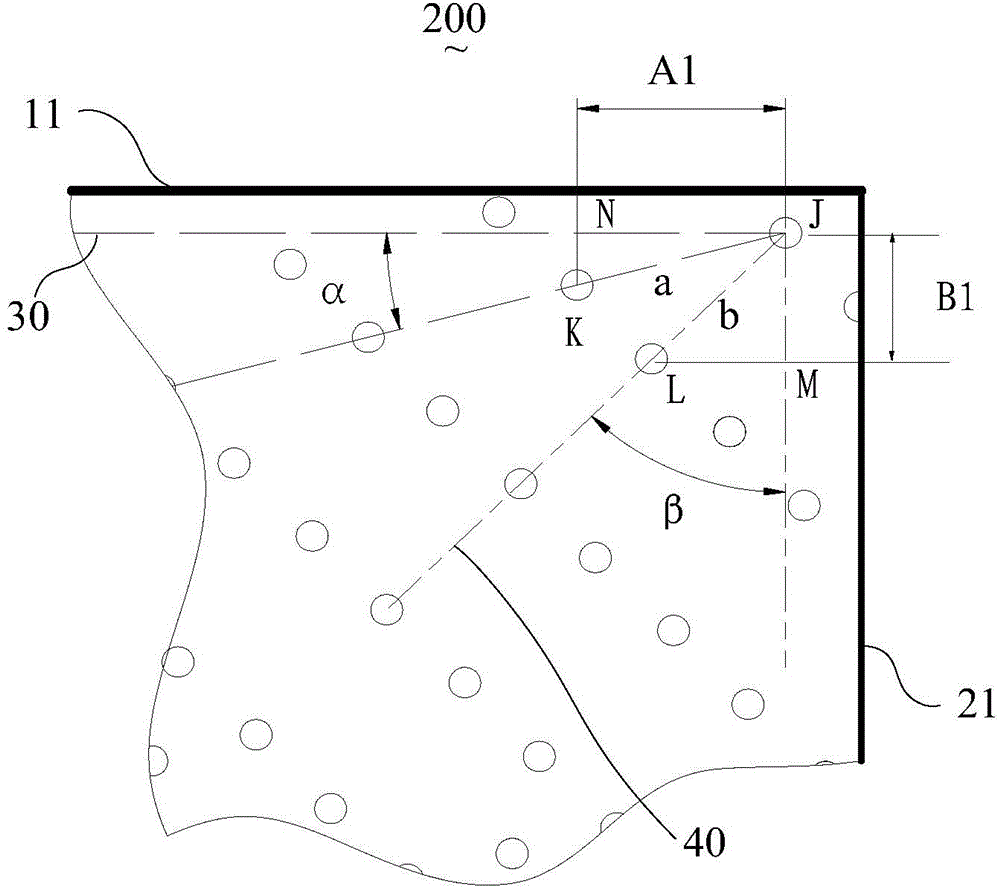

[0034] see figure 1 , figure 1 It is a schematic diagram of the partial arrangement of the embossing on the base paper surface of an embodiment of the present invention. The tissue paper in this embodiment is sequentially cut from the embossed base paper into a plurality of rectangular sheets with a length of L and a width of M. , and stack multiple sheets one after the other in the order they were cut.

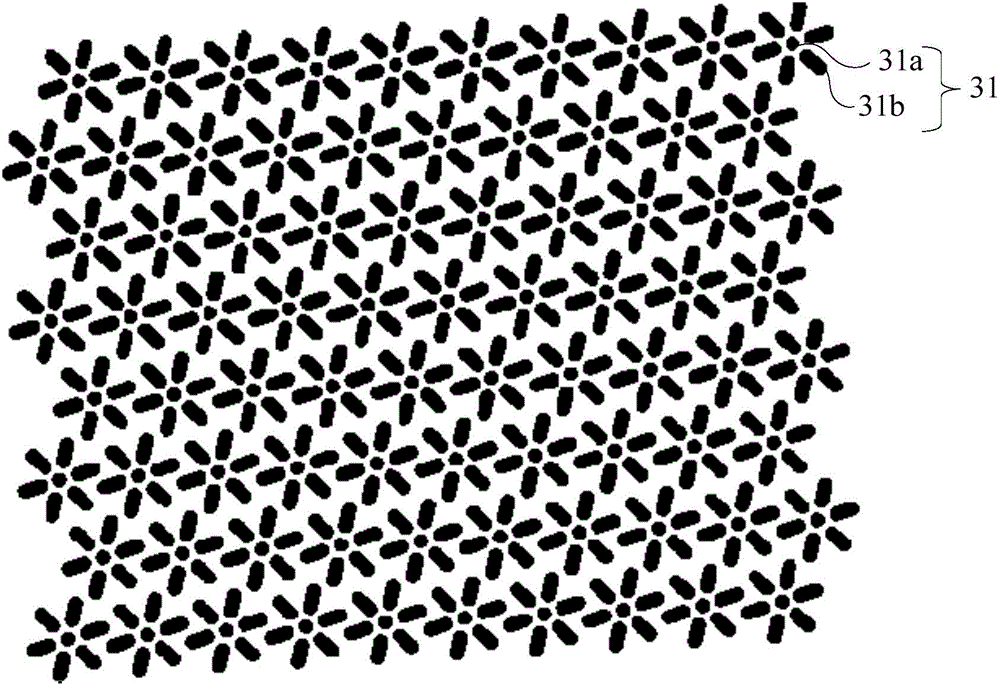

[0035] The base paper 100 is embossed with multiple embossing units, and each embossing unit has the same shape. In this embodiment, the embossing unit is a single pressing point. Of course, the embossing unit can also be other forms flower pattern, such as image 3 An embossed unit in the form of a six-petal flower is shown, Figure 4 Heart-shaped embossed patterns or other forms of embossed patterns, such as flowers, grass, animals, text, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com