Pneumatic wire feeding device for cigarette machine with brush capable of swinging and rotating

A technology for wind wire feeding and cigarette machine, which is applied to the blanking device of wind wire feeding device and the field of wind wire feeding device of cigarette machine, can solve the problems of easy blockage of filter screen, affecting equipment production efficiency, increasing labor intensity of workers, etc. Driving time, cleaning work is easy and simple, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

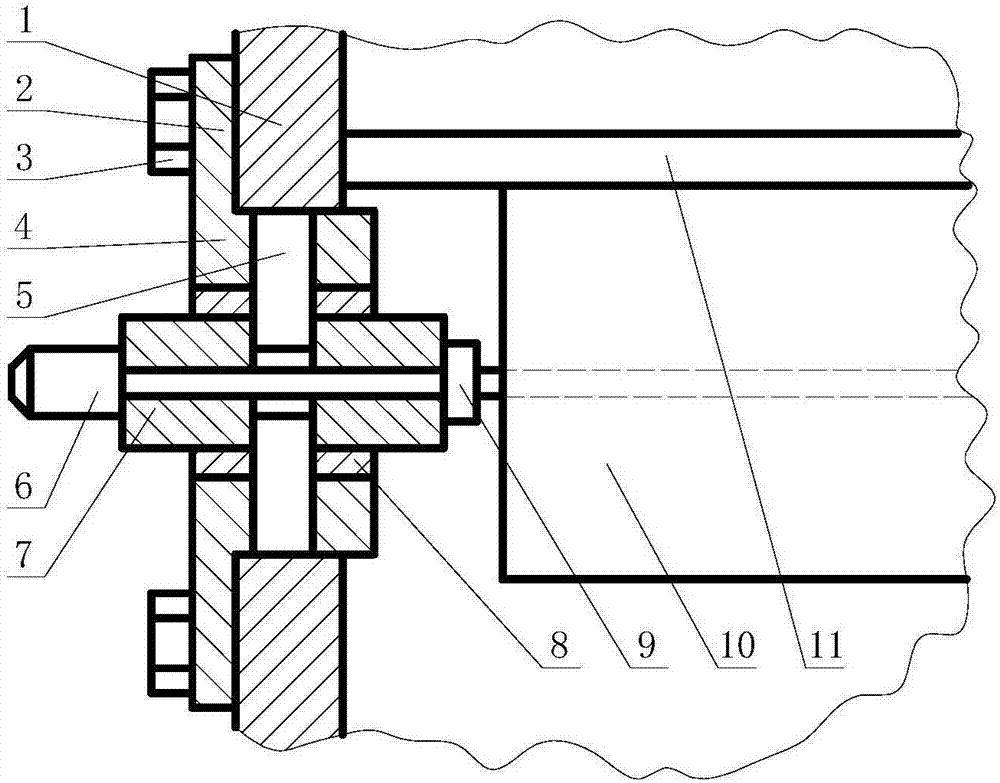

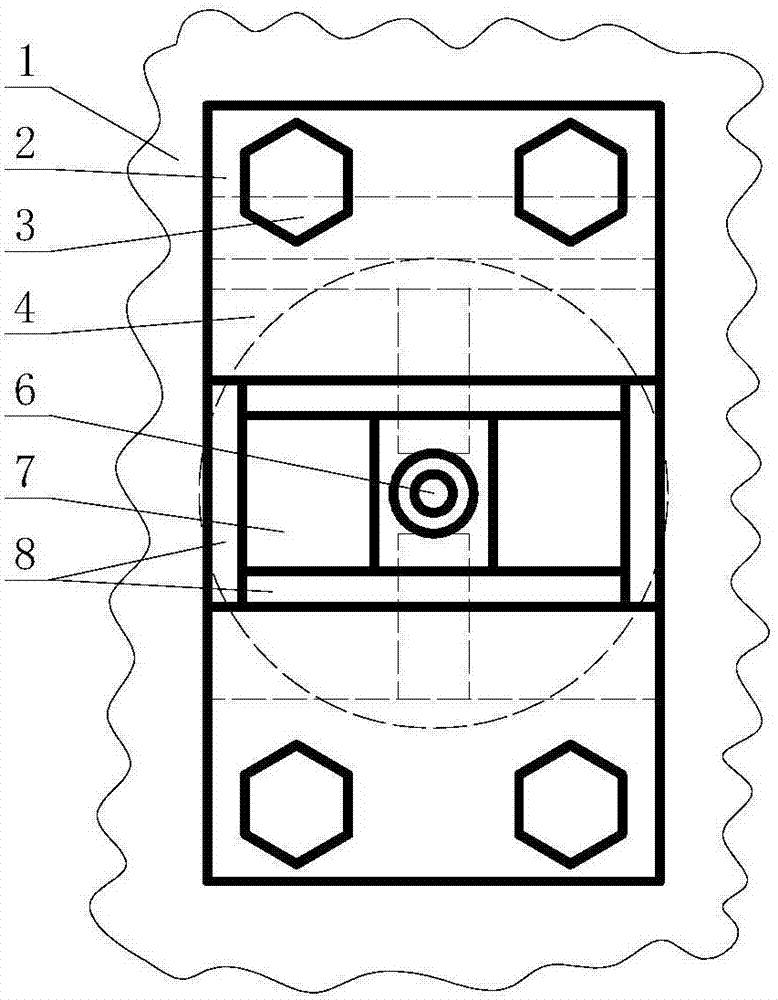

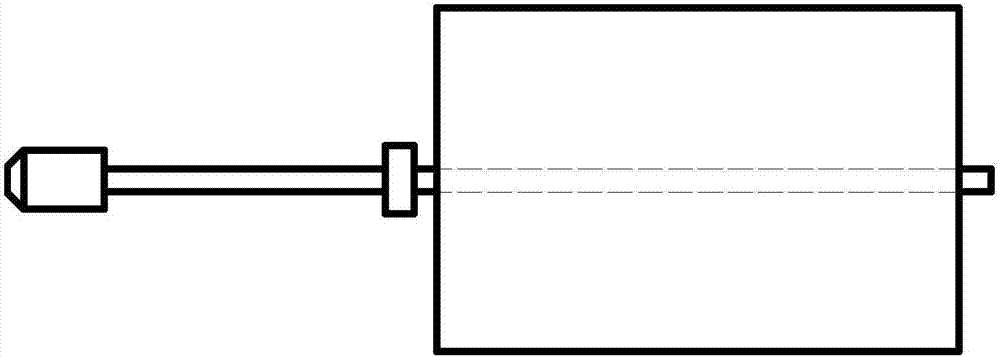

[0030] Combine below Figure 1 to Figure 12 , to further illustrate the present invention: the wind-driven wire feeding device for a cigarette machine with a brush capable of swinging and rotating includes a feeder, and the space surrounded by the main body of the feeder is cuboid, with four The vertical side wall 1 is provided with a filter screen 11 in the horizontal direction in the feeder, and it is characterized in that: the side wall 1 is provided with one to a plurality of rectangular holes, and on the side wall 1, each rectangular hole The top and bottom of the hole are respectively provided with threaded holes, and the two vertical wall surfaces of each rectangular hole are respectively pasted with gaskets 8; the brush device for cleaning the filter screen is set, and the brush device for cleaning the filter screen is set The number of sets is equal to the number of rectangular holes;

[0031] The brush device for each set of cleaning filter screens includes a moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com