Energy-saving glass window with sash capable of rotating by 90 degrees

A technology of glass windows and sash, which is applied to the arrangement of wing leaves, door/window accessories, buildings, etc., and can solve problems such as low safety performance and poor ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

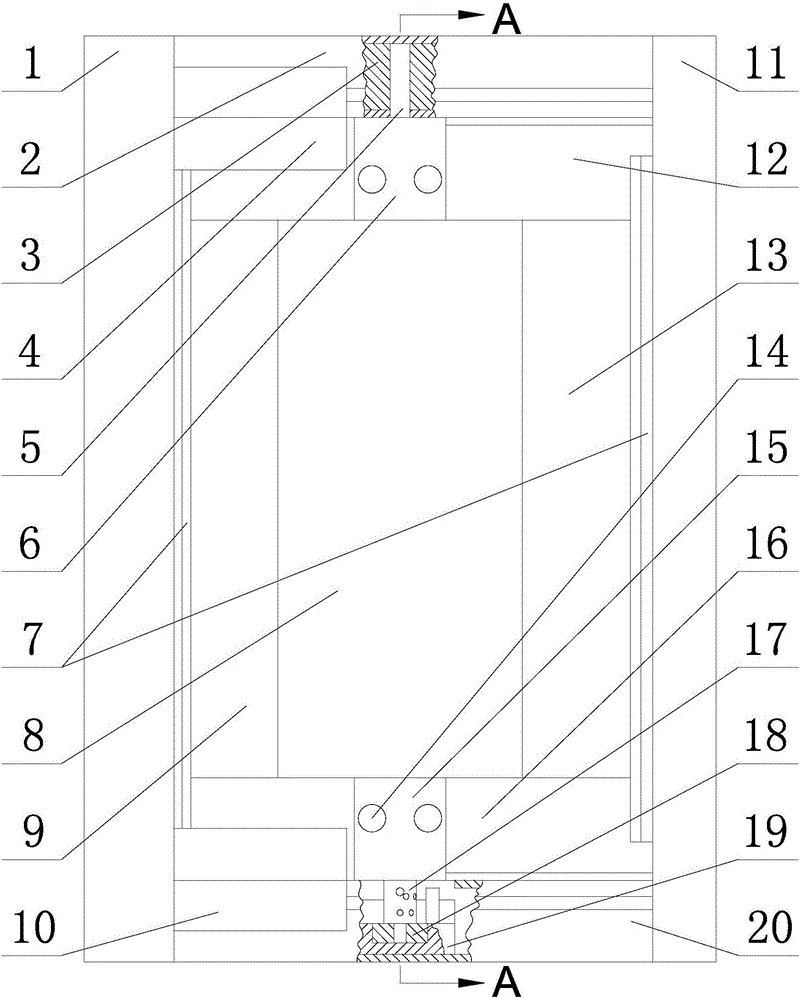

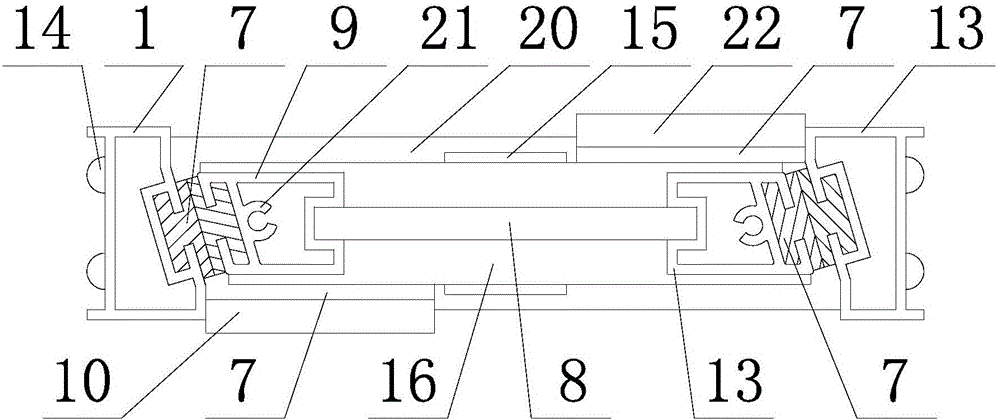

[0113] Embodiment 1: An energy-saving glass window whose sash can be rotated by 90°, including a window frame and a sash, and the sash includes a sash frame and glass, and is characterized in that: the window frame is composed of an upper horizontal frame and a lower horizontal frame , a left frame and a right frame are connected to form a zigzag;

[0114] The upper horizontal frame 2 is connected into a U shape by the upper horizontal frame front vertical plate 203, the upper horizontal frame rear vertical plate 204 and the upper horizontal frame bottom plate 202;

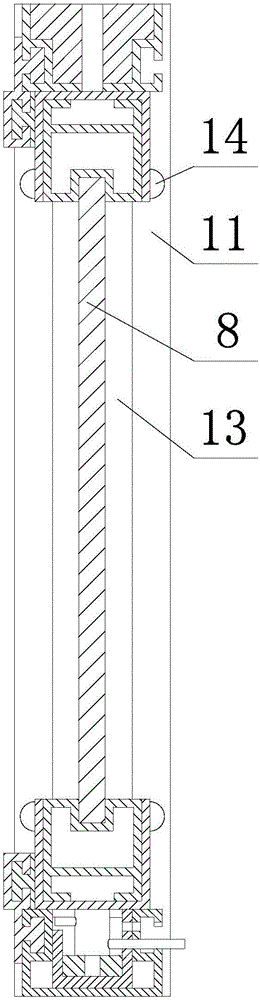

[0115] A front groove frame 26 is provided between the front vertical plate 203 of the upper horizontal frame and the bottom plate 202 of the upper horizontal frame. 26 is connected to the front side of the upper horizontal frame bottom plate 202 as a whole; a rear groove frame 27 is provided between the upper horizontal frame rear vertical plate 204 and the upper horizontal frame bottom plate 202, and the lower p...

Embodiment 2

[0152] Embodiment two: see Figure 7The difference between this embodiment and Embodiment 1 is that the number of said sash is two; The included angle of the front vertical board 101 of the left frame is equal to 180°; The angle is equal to 180°; the angle between the right vertical plate 1303 of the right sash and the front vertical plate 1301 of the right frame plus the angle between the left vertical plate 1104 of the right frame and the front vertical plate 1101 of the right frame is equal to 180°.

Embodiment 3

[0153] Embodiment three: see Image 6 The difference between the present embodiment and the first embodiment is that the middle frame 25 is set, and the middle frame 25 has a front riser 2501 of the middle frame and a rear riser 2502 of the middle frame. The structure is the same, and the structure on the right side is the same as the structure on the right side of the left frame 1; one to several window sashes can be installed on both sides of the middle frame 25.

[0154] The angle between the left vertical board and the left vertical board is less than 90°, and this angle=90°-α. After calculation, α is generally below 10°, which is determined according to the ratio between the thickness and width of the sash, the smaller the ratio, the smaller α. The two dimensions of the projection above the sash on the horizontal plane are the thickness and width of the sash. tgβ=thickness of sash ÷ width of sash, α≥β. see Figure 59 : First draw a rectangle with the width and thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com